Manufacture method of prosthesis with self-antibacterial action

A technology of artificial prosthesis and manufacturing method, applied in the fields of prosthesis, medical science, coating, etc., can solve the problems of unable patients to provide personalized medical services, reducing the service life of artificial prosthesis, and long production cycle of artificial prosthesis, etc. Achieve the effect of eliminating adverse effects, low cost and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

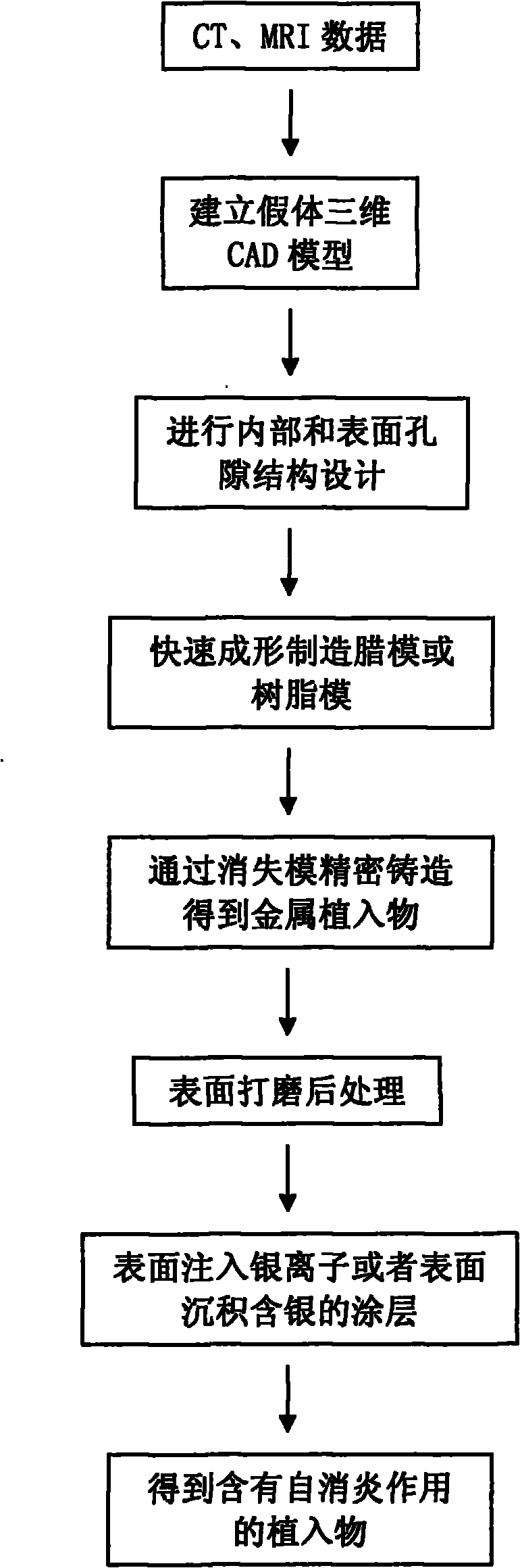

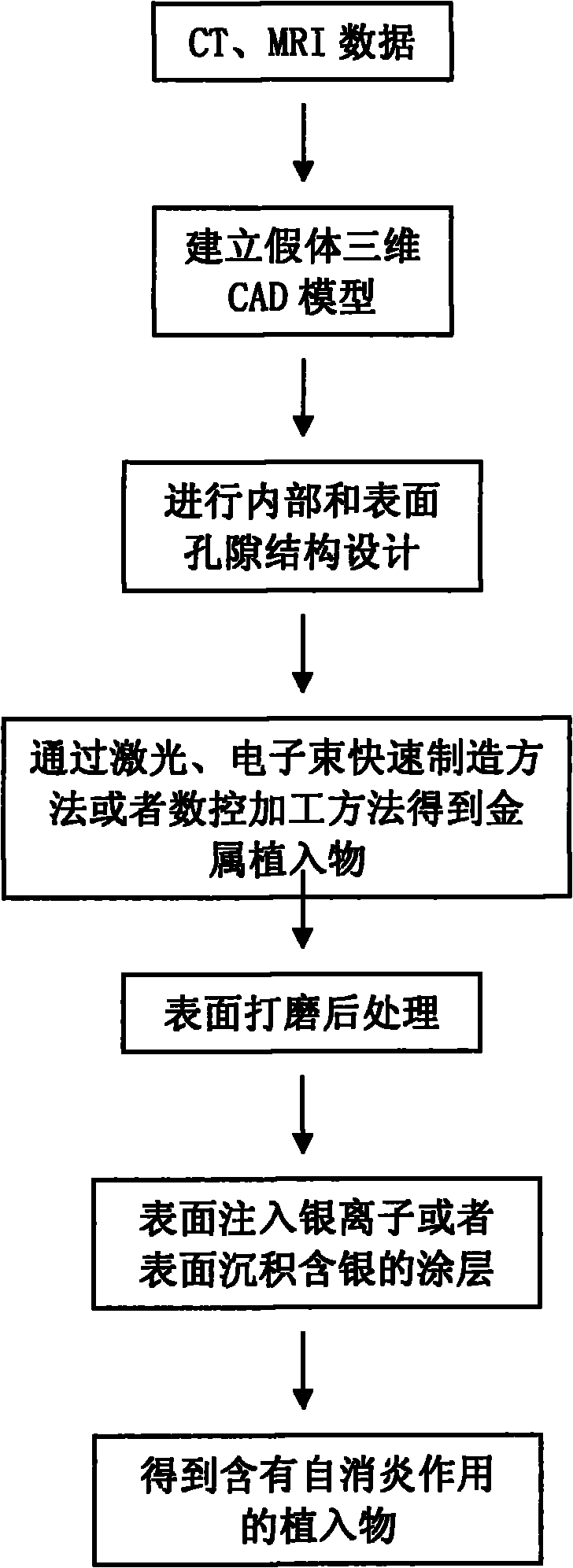

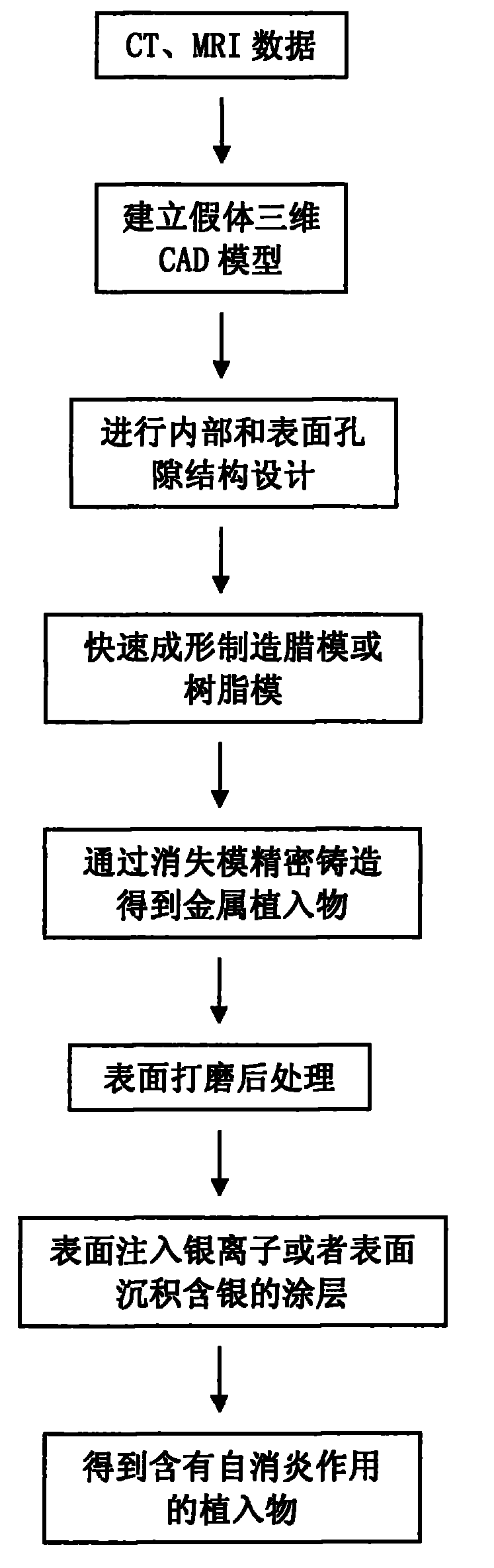

[0025] Attached below figure 1 , 2 The present invention is described in detail, but it is not intended to limit the present invention.

[0026] Specific steps are as follows:

[0027] a) Based on the patient's CT or MRI image data, establish a three-dimensional CAD model of the prosthesis, and design the internal pore structure to obtain the final prosthesis data model suitable for transplantation;

[0028] b) Generate CNC codes from the CAD model, drive rapid prototyping equipment, manufacture wax or resin molds, and obtain metal implants through lost foam precision casting; or directly obtain metal implants through laser electron beam rapid manufacturing methods and numerical control processing methods entry;

[0029] c) After the surface of the implant is polished, a silver ion implantation or deposition process is used to form a silver-containing antibacterial coating on the surface to obtain an implant with self-antibacterial effect.

[0030] The above-mentioned embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com