Method of preparing single-wall carbon nanotube loaded with noble metal nanoparticle

A single-walled carbon nanotube and nanoparticle technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as reducing the crystallinity of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of single-walled carbon nanotubes containing rhodium nanoparticles

[0021] Drill a hole with a diameter of 4mm and a depth of 30mm at the center of the carbon electrode rod with a diameter of 6mm, and fill the hole with a mixture of iron powder, rhodium powder and carbon powder; the mass ratio of iron, rhodium and carbon powder is 2: 4:94; DC current 60A; distance between electrodes 2mm; discharge time 2 minutes; gas pressure 200Torr. Arc discharge in hydrogen / argon (volume ratio 2:3) mixed gas to obtain net-like and cloth-like products. Then heat treatment at 400°C in air for half an hour, soak in hydrochloric acid for 24 hours, and obtain the final sample.

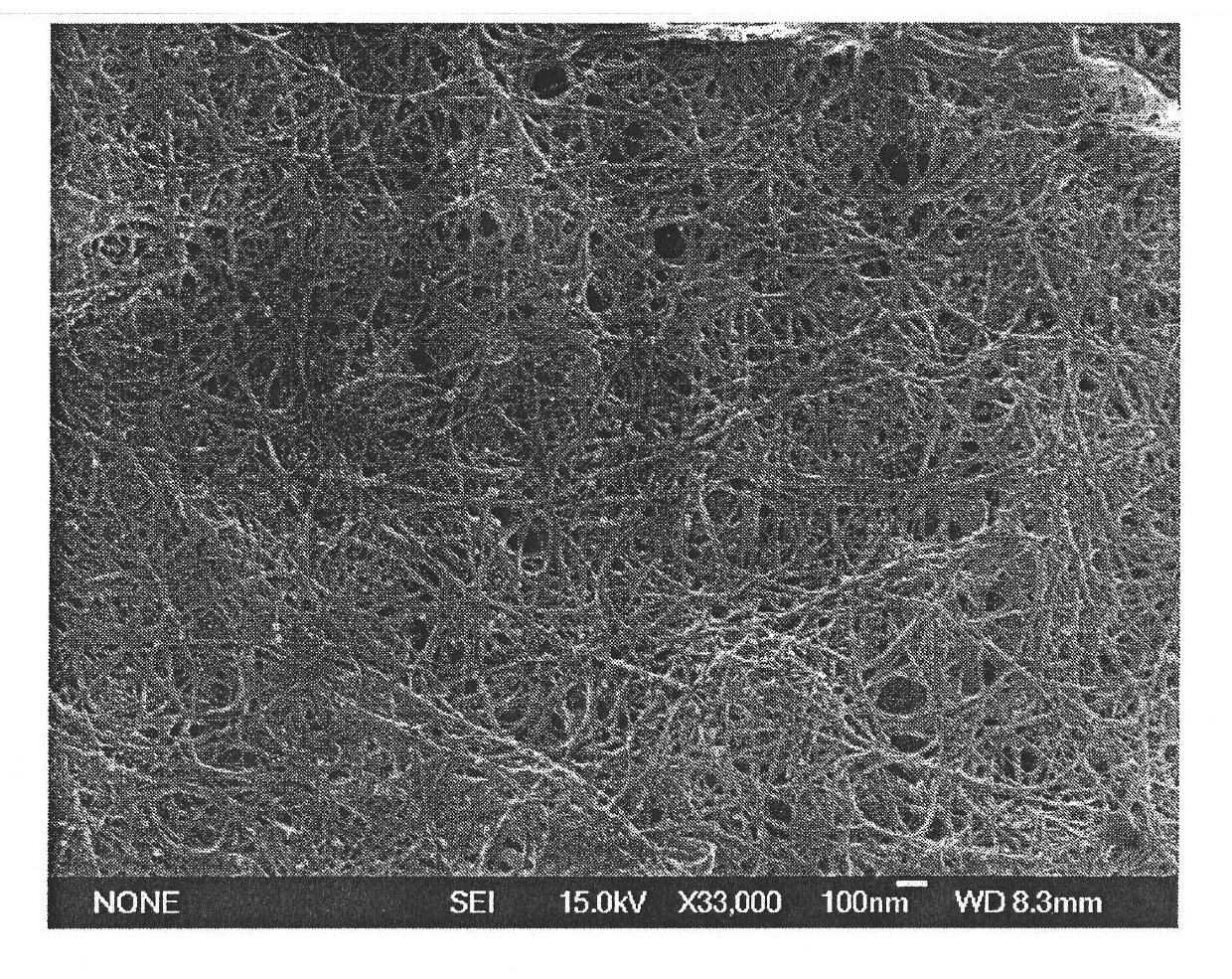

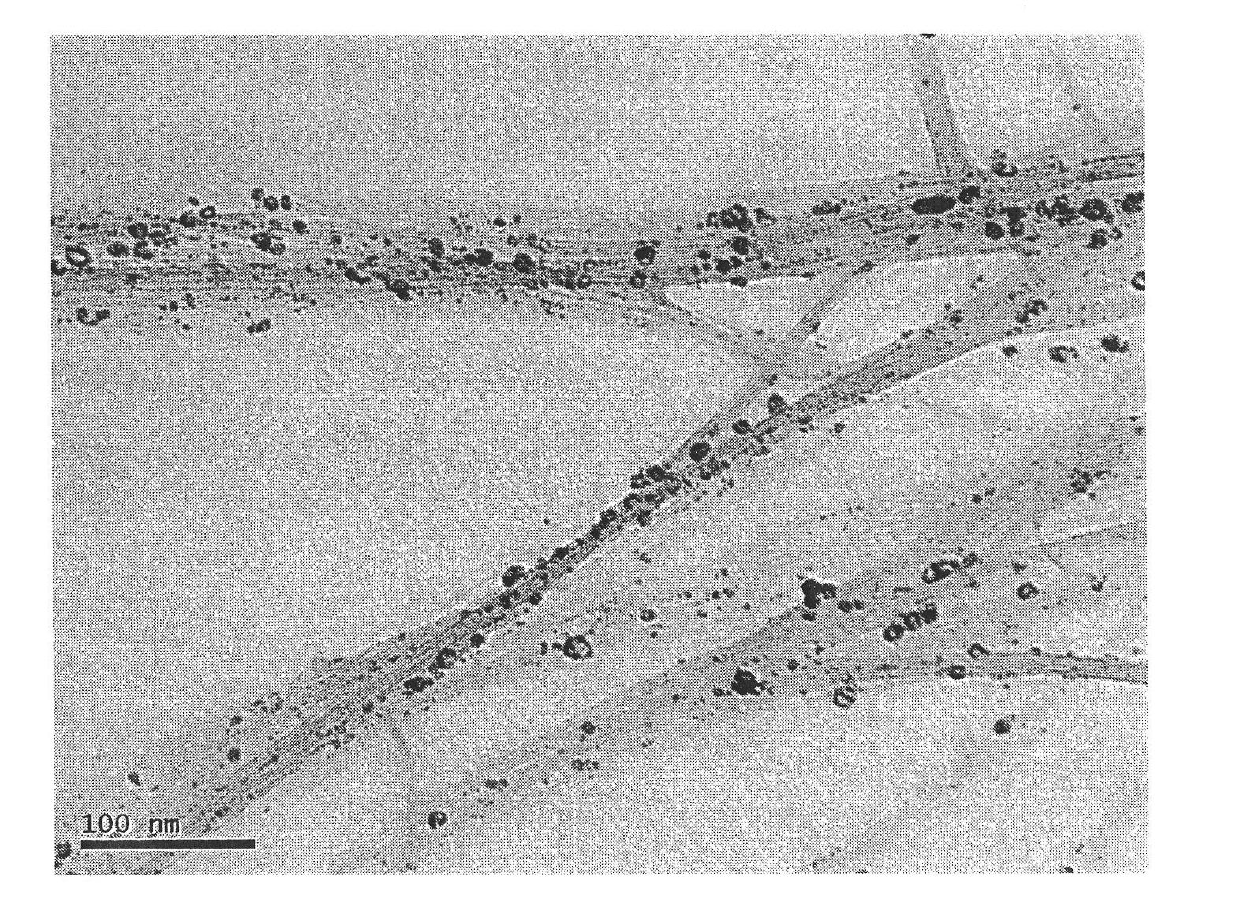

[0022] figure 1 , figure 2 SEM and TEM photographs of single-walled carbon nanotubes containing rhodium nanoparticles.

experiment example 2

[0023] Experimental example 2: Preparation of single-walled carbon nanotubes containing iridium nanoparticles

[0024] Drill a hole with a diameter of 4mm and a depth of 30mm in the center of a carbon electrode rod with a diameter of 6mm, and fill the hole with a mixture of iron powder, iridium powder and carbon powder; the mass ratio of iron, iridium and carbon powder is 2: 4:94; DC current 60A; distance between electrodes 2mm; discharge time 2 minutes; gas pressure 200Torr. Arc discharge in hydrogen / argon (volume ratio 2:3) mixed gas to obtain net-like and cloth-like products. Then heat treatment at 400° C. in air for half an hour, soak in hydrochloric acid for 24 hours, and obtain single-walled carbon nanotubes loaded with iridium nanoparticles.

[0025] Figure 5 is a scanning electron micrograph of single-walled carbon nanotubes loaded with iridium nanoparticles.

experiment example 3

[0026] Experimental Example 3: Preparation of Single-walled Carbon Nanotubes Containing Platinum Nanoparticles

[0027] Drill a hole with a diameter of 4mm and a depth of 30mm at the center of the carbon electrode rod with a diameter of 6mm, and fill the hole with a mixture of iron powder, platinum powder and carbon powder (weight ratio, iron powder: platinum powder: carbon powder = 2: 4 : 94), DC current 60A, electrode distance 2mm, discharge time 2 minutes, gas pressure 200torr. Arc discharge in the mixed gas of hydrogen / argon (volume ratio 2:3) to obtain single-walled carbon nanotube network and cloth products loaded with iron and platinum nanoparticles. Figure 6 It is a scanning electron micrograph of single-walled carbon nanotubes loaded with iron and platinum nanoparticles. Then, heat treatment at 400° C. in air for half an hour, soak in hydrochloric acid for 24 hours, and then single-walled carbon nanotubes loaded with platinum nanoparticles can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com