Catalyst for producing furan by furfural liquid-phase decarbonylation and preparation method

A catalyst and furfural liquid technology, applied in the field of catalysts, can solve the problems of low price, small production capacity, low activity, etc., and achieve the effect of long life and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (a)γ-Al 2 o 3 and K 2 Preparation of O complex support

[0025] According to K 2 O accounts for the proportion of 0.5wt% of the composite carrier, the γ-Al of 5g 2 o 3 Immersion to 0.054gKNO 3 In the aqueous solution, make γ-Al 2 o 3 just happened to be KNO 3 The aqueous solution is completely infiltrated, under mechanical stirring, impregnated at 60°C for 4h, dried at 100°C for 4h, calcined at 450°C for 3h, and then crushed the resultant through a 200-mesh sieve to obtain a powder catalyst composite carrier.

[0026] (b) Preparation of a catalyst for the production of furan by liquid-phase decarbonylation of furfural

[0027] Account for 5wt% of the composite carrier according to palladium (Pd), the PdCl of 0.5g 2 Dissolve in 50mL of hydrochloric acid solution, the concentration of hydrochloric acid is 0.1mol / L, after it is completely dissolved, pour it into a 250mL three-neck flask, blow nitrogen for 10 minutes to exhaust oxygen, pass nitrogen protection and...

Embodiment 2~11

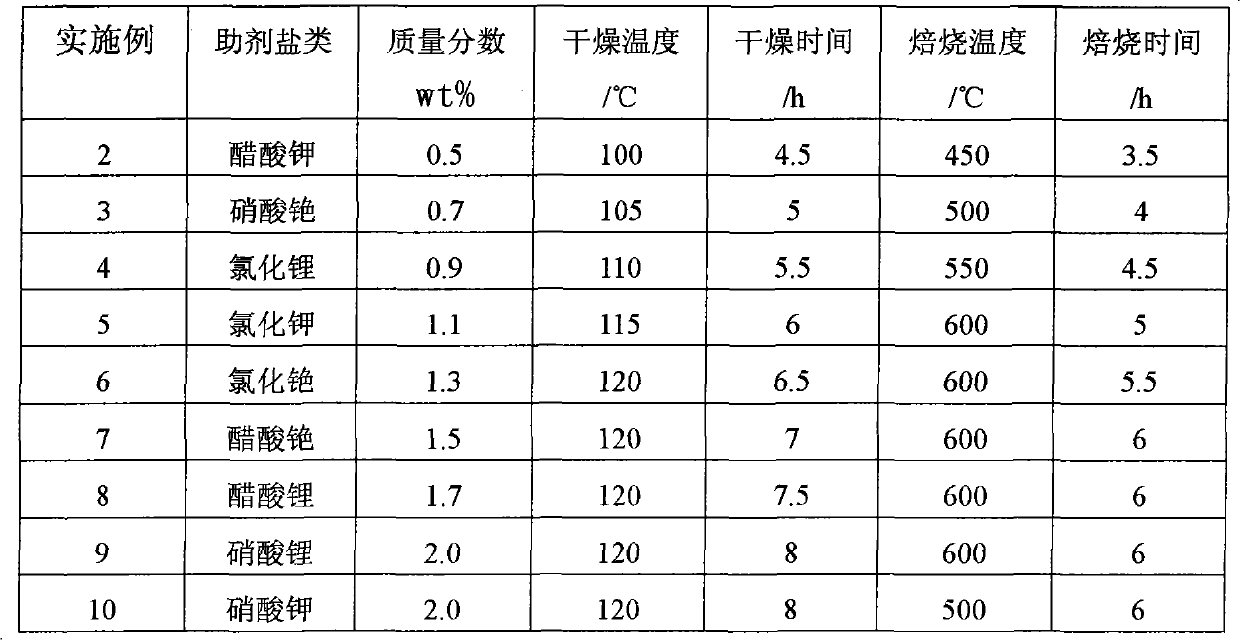

[0034] (a)γ-Al 2 o 3 The conditions for the preparation of the composite carrier with MO are shown in Table 1, and the rest of the conditions are the same as in Example 1.

[0035] Table 1

[0036]

[0037] Note: In Table 1, mass fraction wt% is the proportion value of MO accounting for the composite carrier.

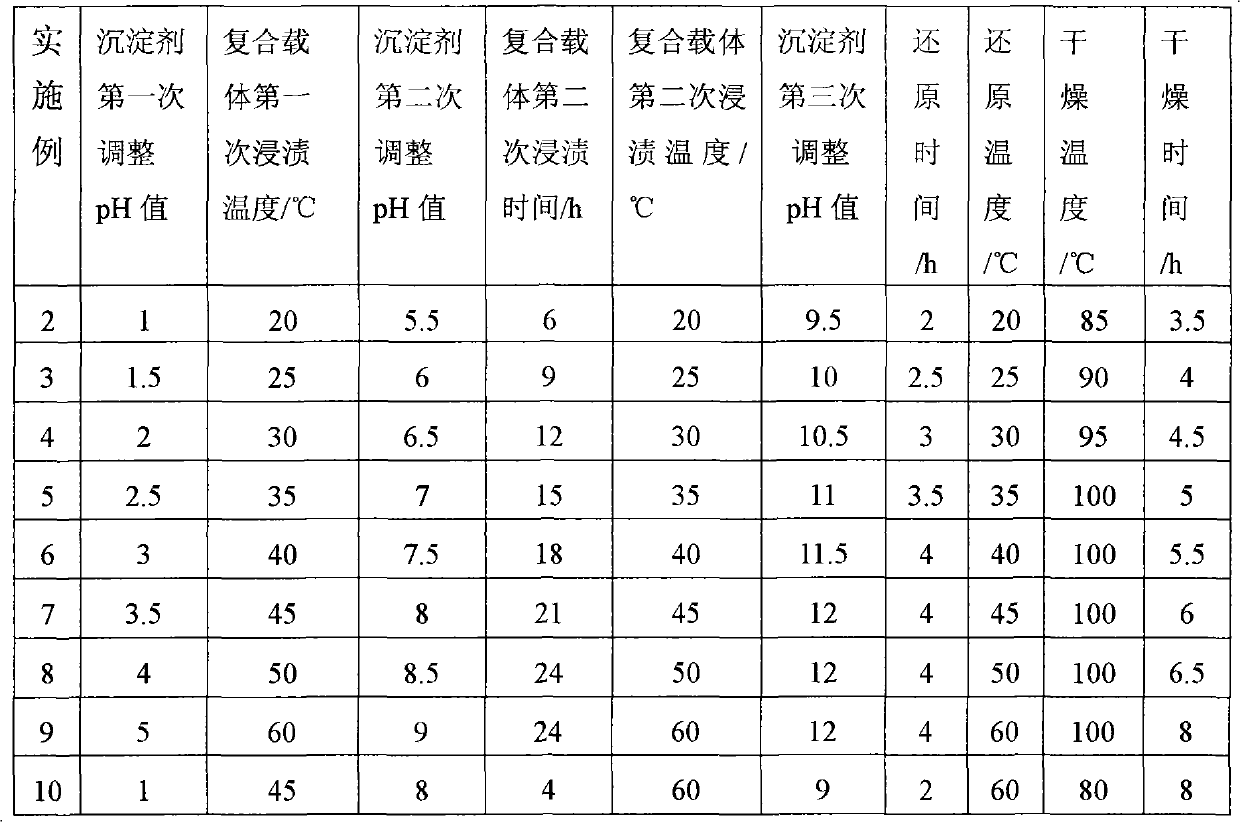

[0038] (b) The preparation conditions of a catalyst for producing furan through liquid-phase decarbonylation of furfural are as shown in Table 2 and Table 3, and all the other conditions are the same as in Example 1.

[0039] Table 2

[0040]

[0041] table 3

[0042] Example

palladium salt

Precipitant

2

3

palladium acetate

4

5

Hydrazine hydrate

6

palladium acetate

sodium bicarbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com