Method for purifying chloroacetic acid by catalytic hydrogenolysis in chloroacetic acid production and application thereof

A technology for catalytic hydrogenolysis and chloroacetic acid, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, chemical instruments and methods, etc., can solve the problems such as whether the chlorinated solution is applicable, the catalyst activity declines rapidly, and the reaction time is long. , to reduce the deactivation trend and activity decline rate, improve the utilization rate of raw materials and product yield, and reduce hydrogen consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

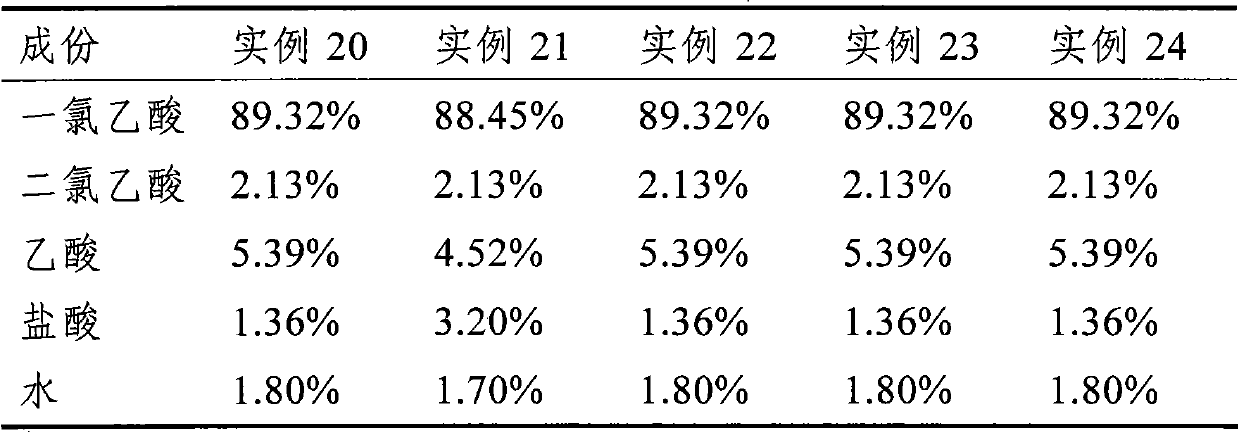

Examples

Embodiment 1

[0038] Example 1. A method for purifying monochloroacetic acid by catalytic hydrogenolysis in the production of monochloroacetic acid. It includes treating the mother liquor after acetic acid chlorination under certain temperature and pressure. The following steps are also included: (1) in a catalytic reactor lined with polytetrafluoroethylene or zirconium material, one or a combination of Group VIII noble metals is installed as a hydrogenolysis catalyst bed, and the ratio of noble metals to the carrier is 3.5% (2) under the gauge pressure of 500kPa and the temperature condition of 150 DEG C, the chlorinated liquid in the monochloroacetic acid production process is made to flow through the fixed bed layer, and the hydrogen-nitrogen mixed gas and the liquid phase are co-flowed into the bed layer; (3) Under the action of the catalyst bed, make all or most of the polychloroacetic acid in the chlorinated liquid hydrogenolyze to produce monochloroacetic acid; (4) take the material...

Embodiment 2

[0039] Example 2. A method for purifying monochloroacetic acid by catalytic hydrogenolysis in the production of monochloroacetic acid. It includes treating the mother liquor after acetic acid chlorination under certain temperature and pressure. The following steps are also included: (1) in a catalytic reactor lined with polytetrafluoroethylene or zirconium material, one or a combination of Group VIII noble metals is installed as a hydrogenolysis catalyst bed, and the ratio of noble metals to the carrier is 2% (2) under the gauge pressure of 800kPa and the temperature condition of 100 DEG C, make the chlorinated liquid in the monochloroacetic acid production process flow through the fixed bed layer, and simultaneously make the hydrogen-nitrogen mixed gas and the liquid phase co-flow into the bed layer; (3) Under the action of the catalyst bed, make all or most of the polychloroacetic acid in the chlorinated liquid hydrogenolyze to produce monochloroacetic acid; (4) take the ma...

Embodiment 3

[0040] Example 3. A method for purifying monochloroacetic acid by catalytic hydrogenolysis in the production of monochloroacetic acid. It includes treating the mother liquor after acetic acid chlorination under certain temperature and pressure. It also includes the following steps: (1) in a catalytic reactor lined with polytetrafluoroethylene or zirconium material, one or a combination of Group VIII noble metals is installed as a hydrogenolysis catalyst bed, and the ratio of noble metals to the carrier is 0.1% (2) under the gauge pressure of 100kPa and the temperature condition of 200 DEG C, the chlorinated liquid in the monochloroacetic acid production process is made to flow through the fixed bed layer, and the hydrogen-nitrogen mixed gas and the liquid phase are co-flowed into the bed layer; (3) Under the action of the catalyst bed, make all or most of the polychloroacetic acid in the chlorinated liquid hydrogenolyze to produce monochloroacetic acid; (4) take the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com