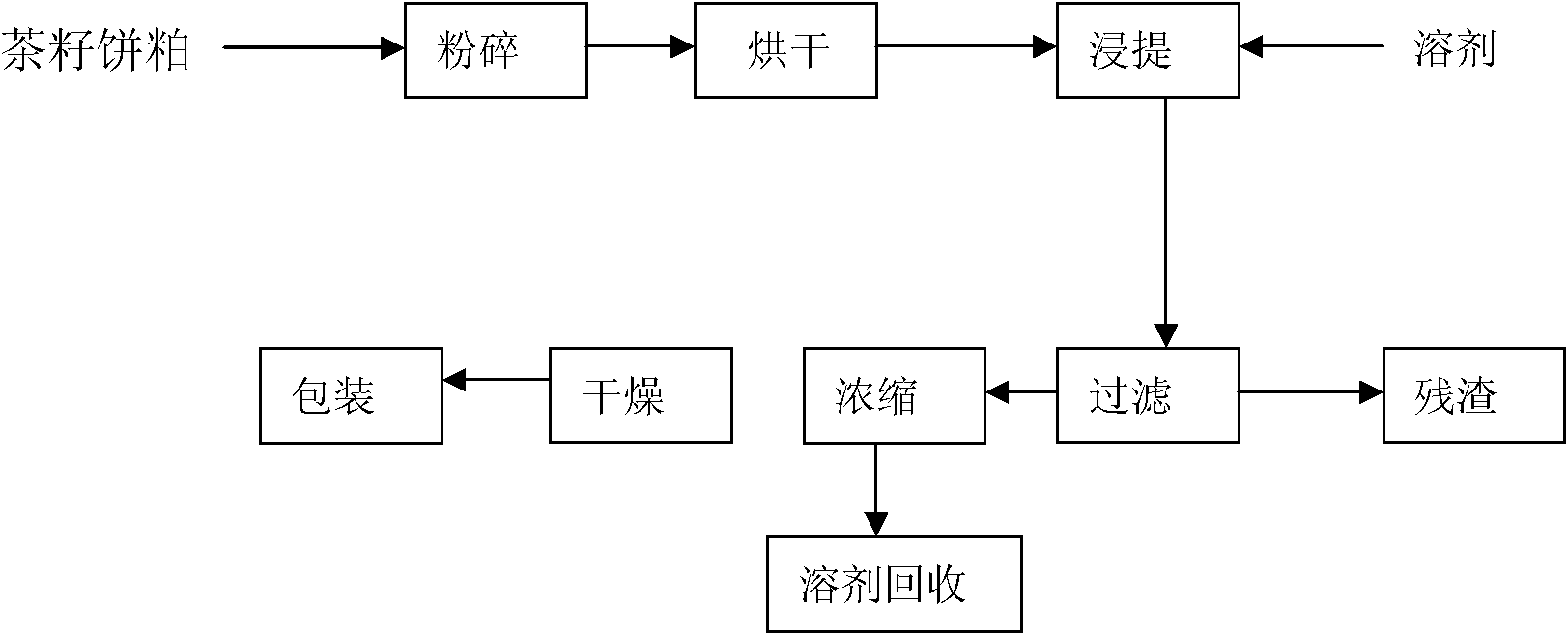

Process for extracting tea saponin from tea seed cakes or meal

A technology for tea seed cake and tea saponin, which is applied in the preparation of sugar derivatives, steroids, sugar derivatives, etc., can solve the problems of pollution, not very obvious effect, large energy consumption, etc. The effect of reducing the decolorization link and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 2000kg of raw material and crush it to a particle size of 1-3mm, then send it to a steamer for 10-30 minutes to dry until the water content of the raw material is less than 7%; then use ethanol solution with a volume concentration of 75% as a solvent, solvent Proportioned with the tea seed cake by weight percentage 3:1, enter the horizontal extraction machine and extract at a temperature of 40-50°C for 1-1.5 hours, the slag liquid is automatically separated after extraction twice, and the extraction liquid enters the Two-stage long-tube evaporator, primary temperature 50-80°C, secondary temperature 70-95°C; after 2-4 minutes, it is automatically input into a vacuum concentration tank, and the remaining temperature is naturally concentrated for 2-4 hours, and dried to a light yellow powder Tea saponin 276kg, yield 13.8%. (Product to feed ratio) is 1.8% higher than the original process. The content of the active substance is 81.5% according to the test; the pH valu...

Embodiment 2

[0030] Weigh 2000kg of raw material and crush it to a particle size of 1-3mm, then send it to a steamer for 10-30 minutes and dry until the water content of the raw material is less than 7%; then use an ethanol solution with a volume concentration of 85% as a solvent, solvent Proportioned with tea seed cake by weight percentage 4:1, enter the horizontal rotary extraction machine and extract for 1-1.5 hours at a temperature of 40-50°C, after two extractions, the slag liquid is automatically separated, and the extraction liquid enters the Two-stage long-tube evaporator, primary temperature 50-80°C, secondary temperature 70-95°C, after 2-4 minutes, it will automatically enter the vacuum concentration tank, after which the remaining temperature will be naturally concentrated for 2-4 hours, and dried to light yellow powder Tea saponin 278.5kg, yield 13.93%. The tests have reached and exceeded the quality level of the original process.

Embodiment 3

[0032] Weigh 700 tons of raw materials, operate according to the process of Example 2, run continuously for 17 days (24 hours a day), and finally obtain 98.5 tons of tea saponin. The yield rate is 14.07%. The product was sent to the Anhui Provincial Product Quality Supervision and Inspection Institute for inspection. The mass fraction of tea saponin 64.30% was 14% higher than the original process 50%; the pH value of 6.0 was 0.1-0.3 higher than the original process; the content of active substances was 81.5% higher than the original process 5-15%; the color is light yellow and similar to the original process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com