Enzyme electrode and preparation method thereof

An enzyme electrode and electrode technology, applied in the field of biosensors, can solve problems such as changing enzyme activity, and achieve the effects of good stability, high sensitivity and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

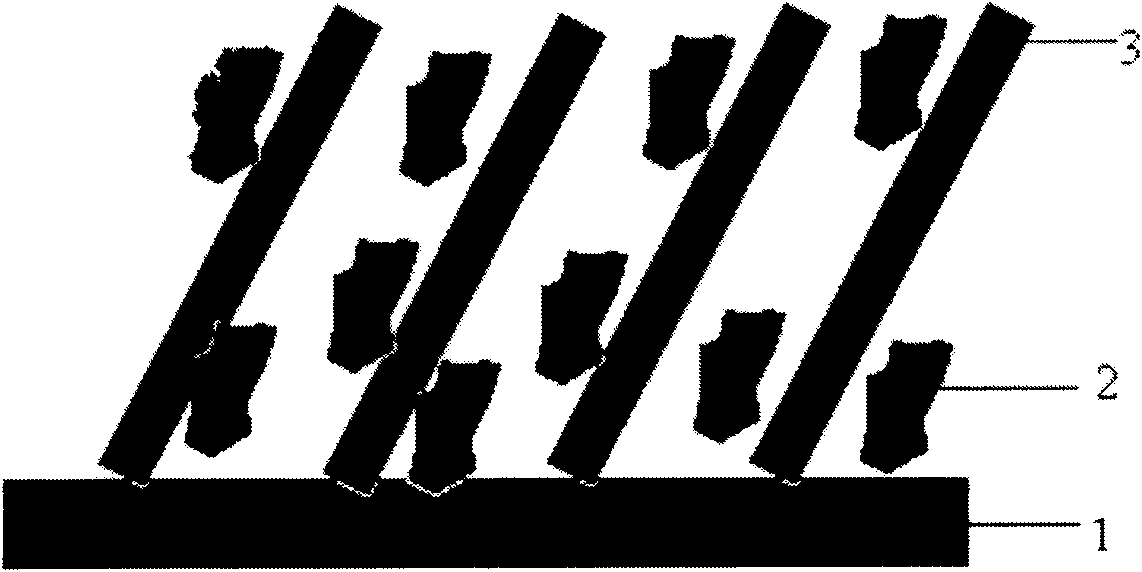

[0029] Preparation of Sb-doped SnO 2 Nanowires: Put the gold-plated silicon chip into a magnetic boat filled with tin powder and antimony powder, wherein the mass ratio of tin powder and antimony powder is 100:5, at 850°C and 80sccm N 2 Sb-doped SnO can be obtained on the surface of a silicon wafer by heating under airflow conditions for 2 hours 2 Nanowires;

[0030] Doped SnO containing 1 mg / mL of the above Sb 2 The ethanol solution of nanowires and the phosphate buffer solution containing 2 mg / mL HRP were uniformly mixed in equal volumes, and 6 μL was drip-coated on the surface of the glassy carbon electrode treated by the above method, and dried in the refrigerator at 4 ° C to prepare the nanowire / HRP composite Membrane enzyme electrode.

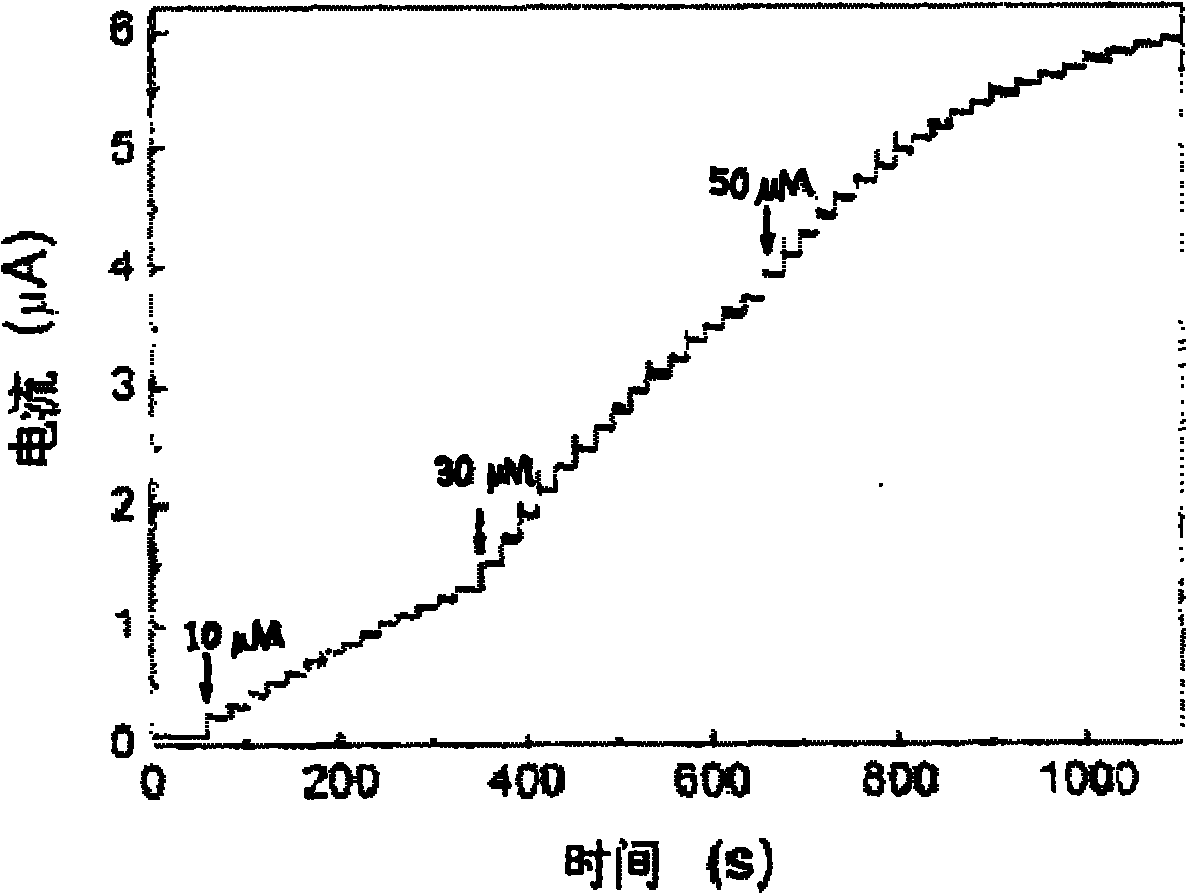

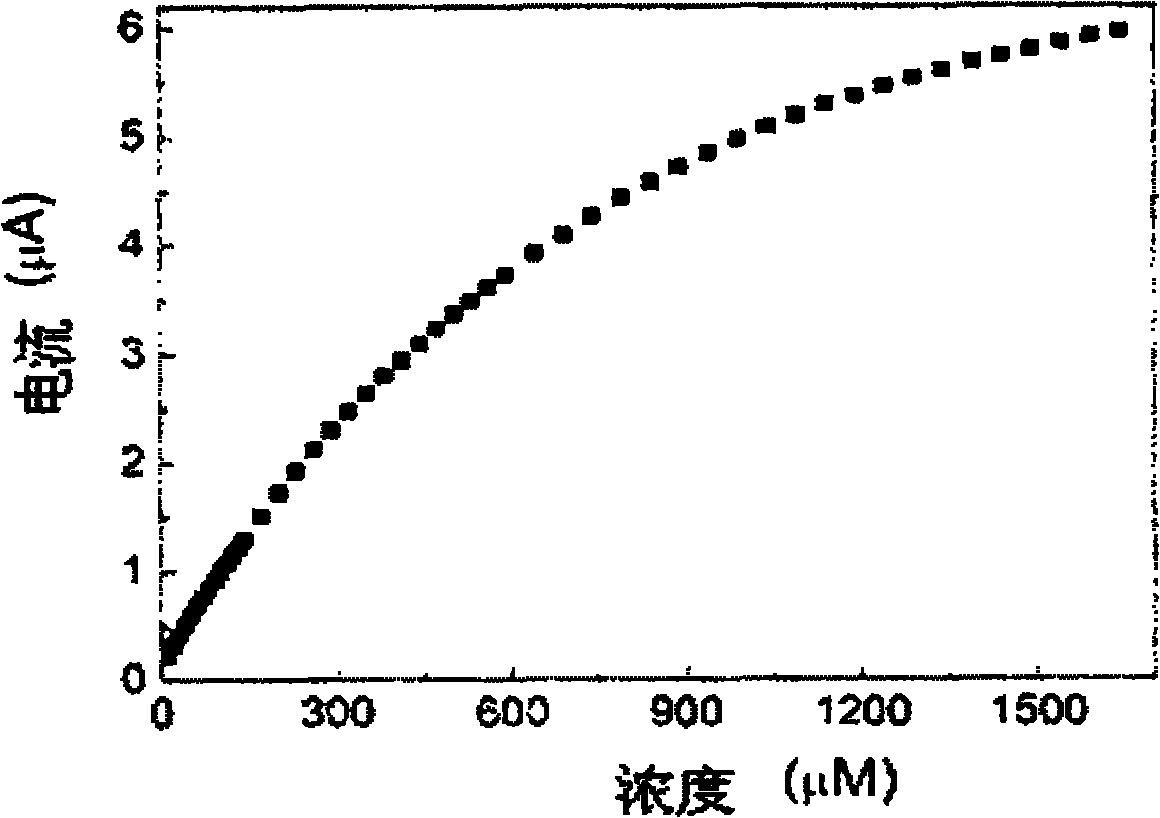

[0031] A three-electrode system was used to test the above-mentioned enzyme electrode, in which the platinum electrode was used as the counter electrode, the Ag / AgCl (saturated KCl) electrode was used as the reference electrode, the ab...

Embodiment 2

[0033] Doped SnO with 2mg of Sb 2The nanowires were dispersed in 1 mL of 1wt% Nafion ethanol solution, mixed evenly with a phosphate buffer solution containing 6 mg / mL myoglobin (Mb) at a volume ratio of 1:0.9, and 7 μL was drip-coated on the gold treated by the above method. The surface of the electrode was dried in a refrigerator at 4° C. to prepare a nanowire / Mb composite film enzyme electrode.

[0034] According to the method in Example 1 with different concentrations of H 2 o 2 The enzyme electrode of Example 2 was tested as a substrate, and the sensitivity had a good linear relationship in the range of 1-600 μM, and the stability was good, and 91% of the activity was still maintained after four weeks of testing.

Embodiment 3

[0036] Sb doped SnO 2 The nanowires were dispersed into an acetic acid solution containing 0.3wt% chitosan (the concentration of acetic acid in the solution was 0.05M), wherein the Sb doped SnO in the solution 2 The concentration of the nanowires is 1 mg / mL, and the solution is uniformly mixed with the phosphate buffer solution containing 2 mg / mL cytochrome C at a volume ratio of 1:1.25, and 8 μL is drip-coated on the surface of the cleaned pyrolytic graphite electrode, and the refrigerator is 4 °C and then dried to prepare the nanowire / cytochrome C composite film enzyme electrode.

[0037] According to the method in Example 1 with different concentrations of H 2 o 2 The enzyme electrode of embodiment 3 is tested as substrate, has very wide linear range (10~400 μ M), very high sensitivity (90mA M -1 cm -2 ) and good stability, the test still maintained 85% of the activity after one month.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com