Hydrophilic sheet and method of imparting ultrahigh hydrophilicity to substrate surface

A substrate surface, hydrophilic technology, applied in the direction of anti-pollution methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as decreased vision, and achieve the effect of preventing fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0105] The (meth)acrylic polymer can be prepared, for example, using a mixture containing one or more monomer components, and can be carried out by an appropriate method such as a solution polymerization method, an emulsion polymerization method, a bulk polymerization method, or a suspension polymerization method. .

[0106] In the preparation of the (meth)acrylic polymer, a polymerization initiator can be used. Examples of the polymerization initiator include peroxides such as hydrogen peroxide, benzoyl peroxide, and t-butyl peroxide.

[0107] Although the polymerization initiator is desirably used alone, it can also be used as a redox type polymerization initiator in combination with a reducing agent.

[0108] Examples of the reducing agent include ionized salts such as sulfites, bisulfites, iron salts, copper salts, and cobalt salts; amines such as triethanolamine; and reducing sugars such as aldose and ketose.

[0109] As a polymerization initiator, an azo compound is al...

Embodiment 1

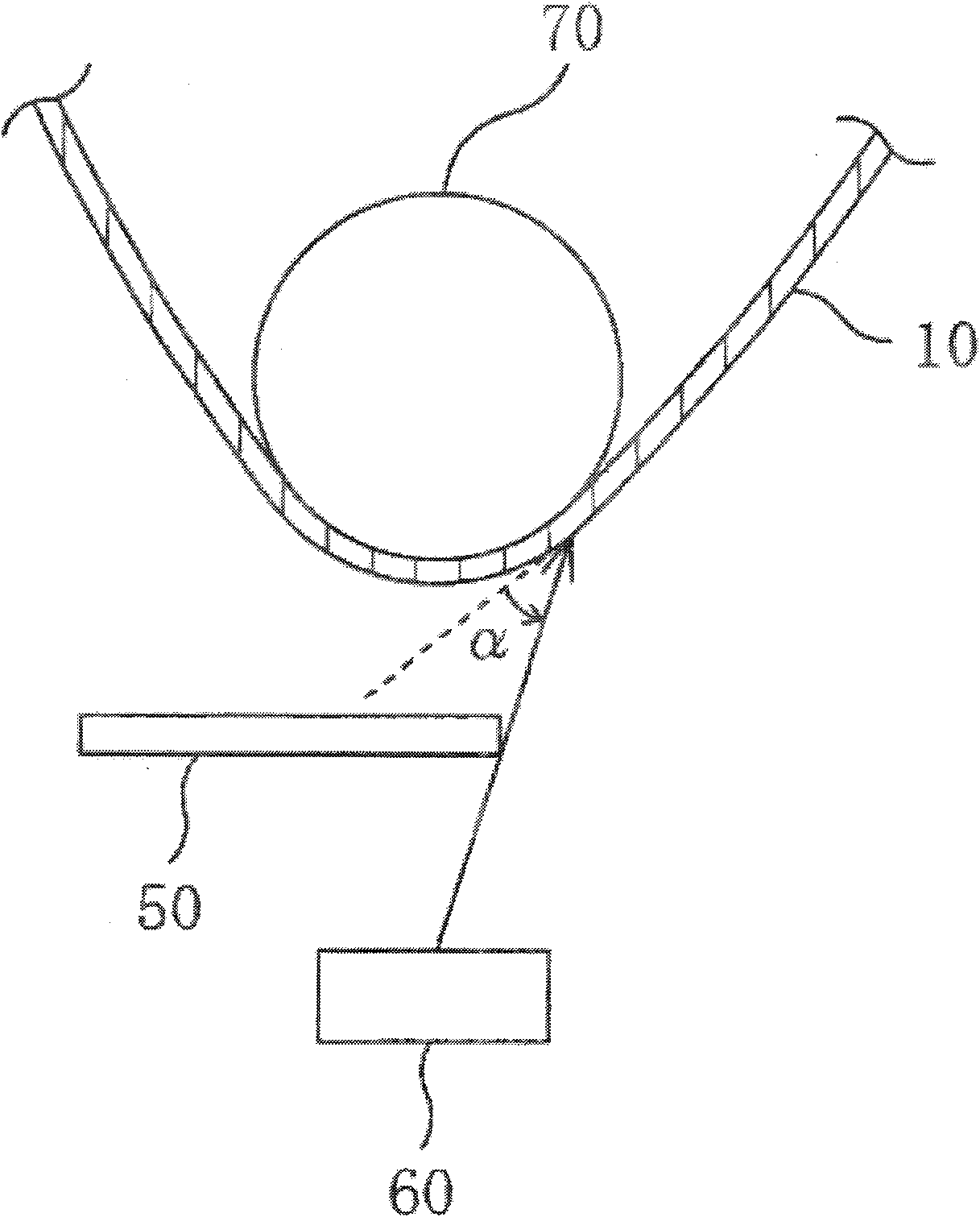

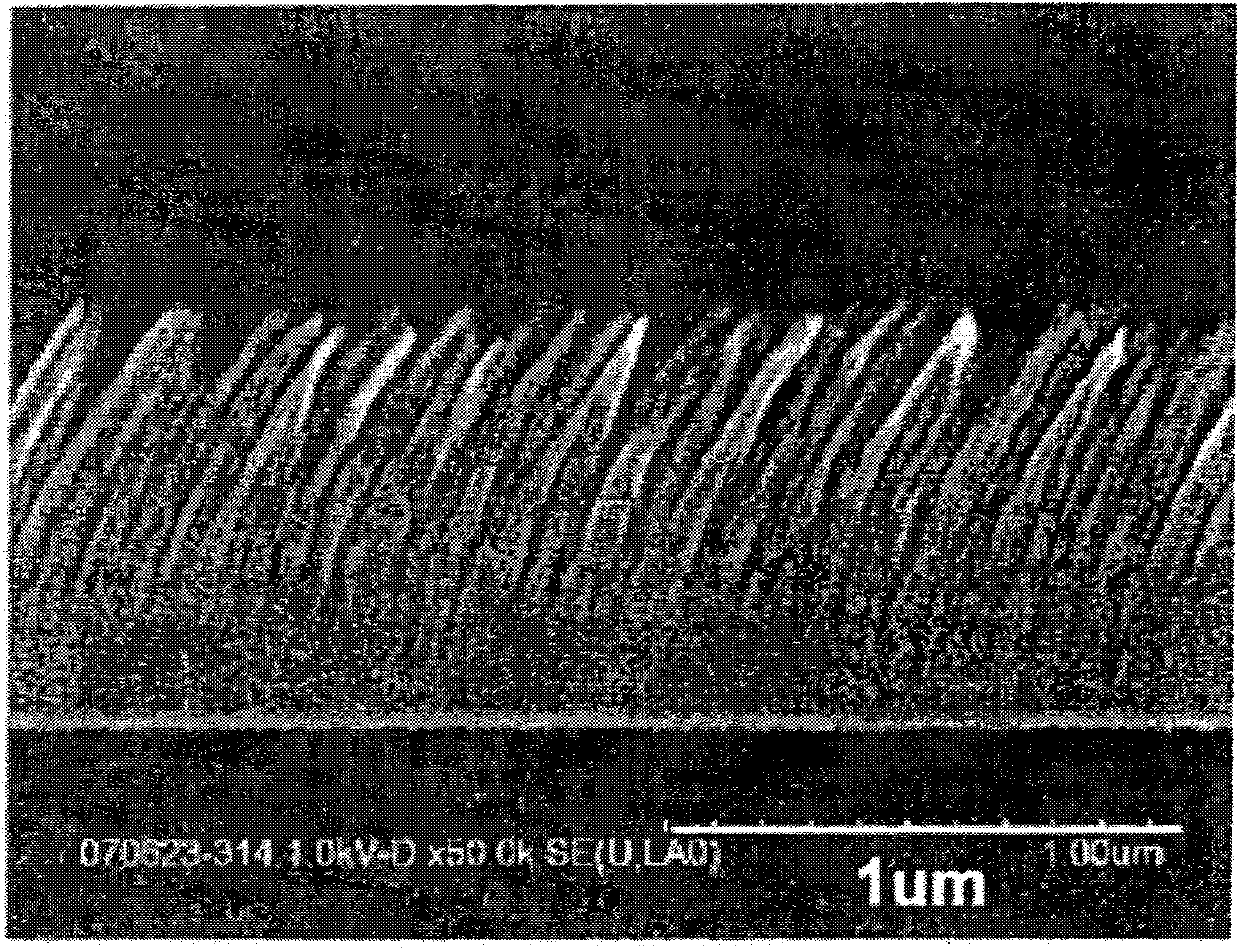

[0147] (Oblique evaporation method)

[0148] Slanted columnar structures are formed using as Image 6 The coiled electron beam (EB) vacuum evaporation setup shown. A polyester film (manufactured by Toray, Lumirror S10) with a thickness of 50 μm was used as the substrate, and silicon dioxide (SiO 2 ), set the line speed to 0.2m / min, and the ultimate vacuum in the chamber is 4×10 -5 The tort and EB outputs were produced under the conditions of (emission current) 500mA and an incident angle of vapor deposition of 60 degrees.

[0149] (Production of hydrophilic sheet)

[0150] With respect to 100 parts of acrylic polymer obtained from a monomer mixture liquid composed of 100 parts of butyl acrylate and 3 parts of acrylic acid, 2 parts of polyisocyanate compound (manufactured by Nippon Polyurethane Industry, trade name: Coronate L), epoxy compound (manufactured by Mitsubishi Gas Chemical, trade name: Tetrad C) 0.6 parts were uniformly mixed to prepare an acrylic adhesive soluti...

Embodiment 2

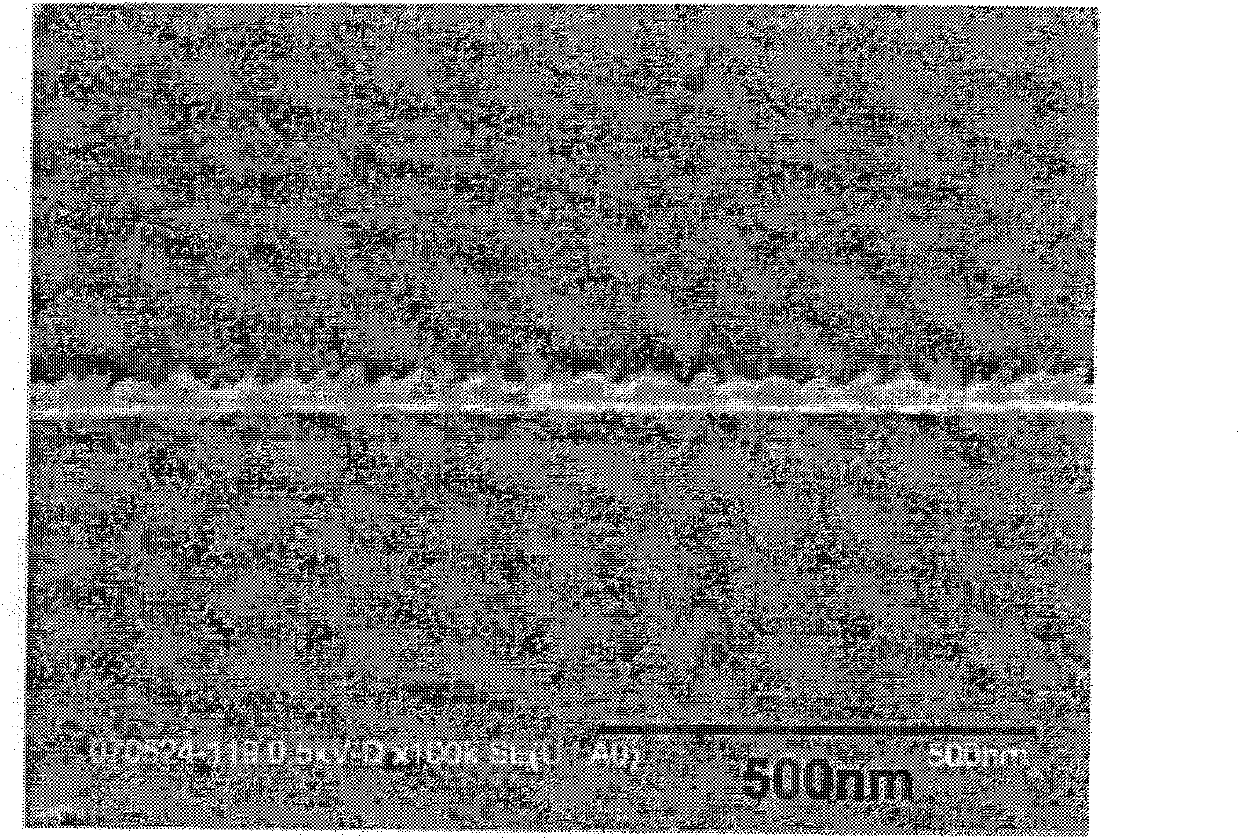

[0154] Except that the line speed is set to 1.7m / min, the SiO of the evaporation source is made 2 Evaporate to form an inclined columnar structure on the substrate to make a hydrophilic sheet. The evaluation results are shown in Table 1. In addition, in Figure 8 The cross-sectional SEM photograph of the obtained hydrophilic sheet is shown in . In addition, in Figure 9 A photograph showing the evaluation of the anti-fogging property is shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com