Method for preparing graphene

A graphene and metal technology, applied in the field of preparation of nanomaterials, can solve the problem that graphite oxide is not easy to redisperse, etc., and achieve the effects of high yield and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 : Palladium chloride as a catalyst to catalyze the hydrogenation of graphene oxide to prepare graphene

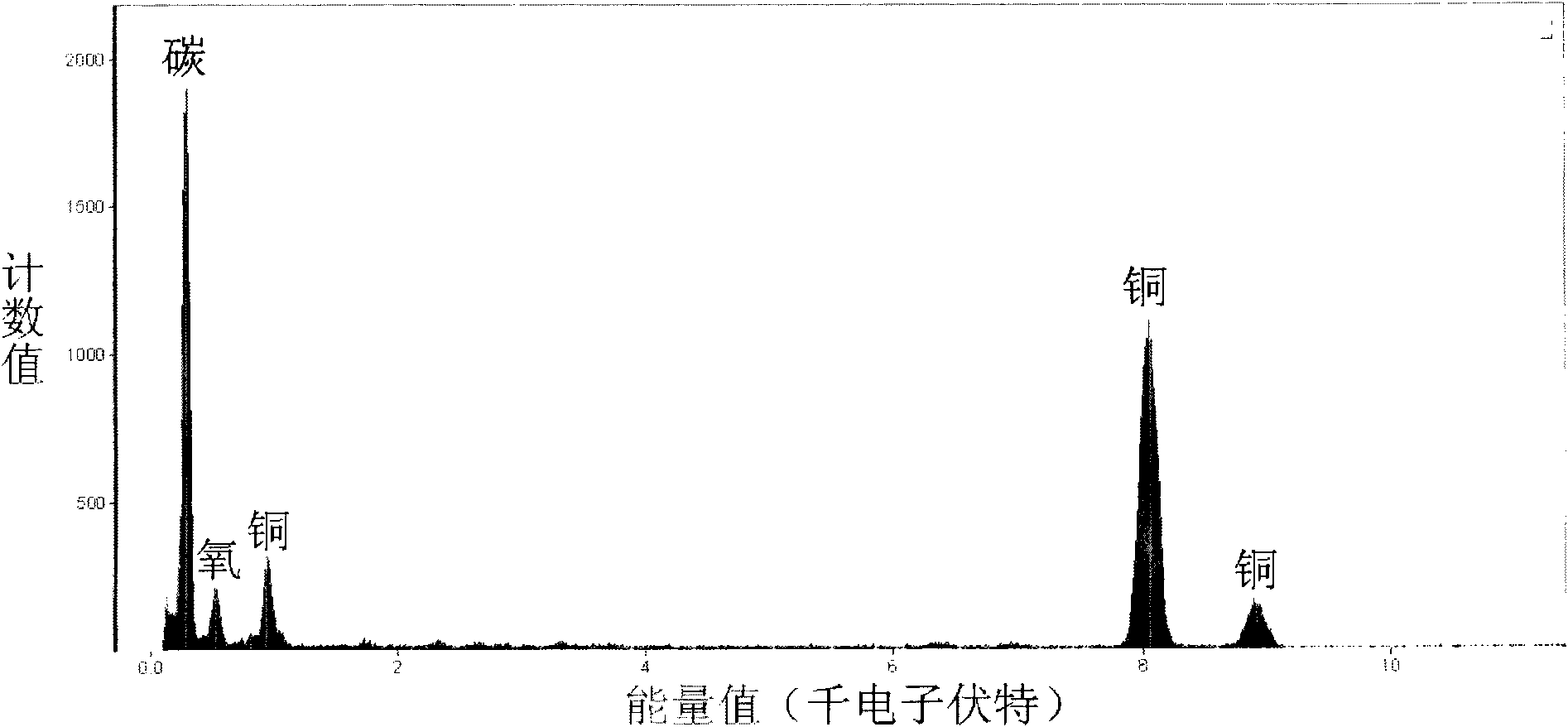

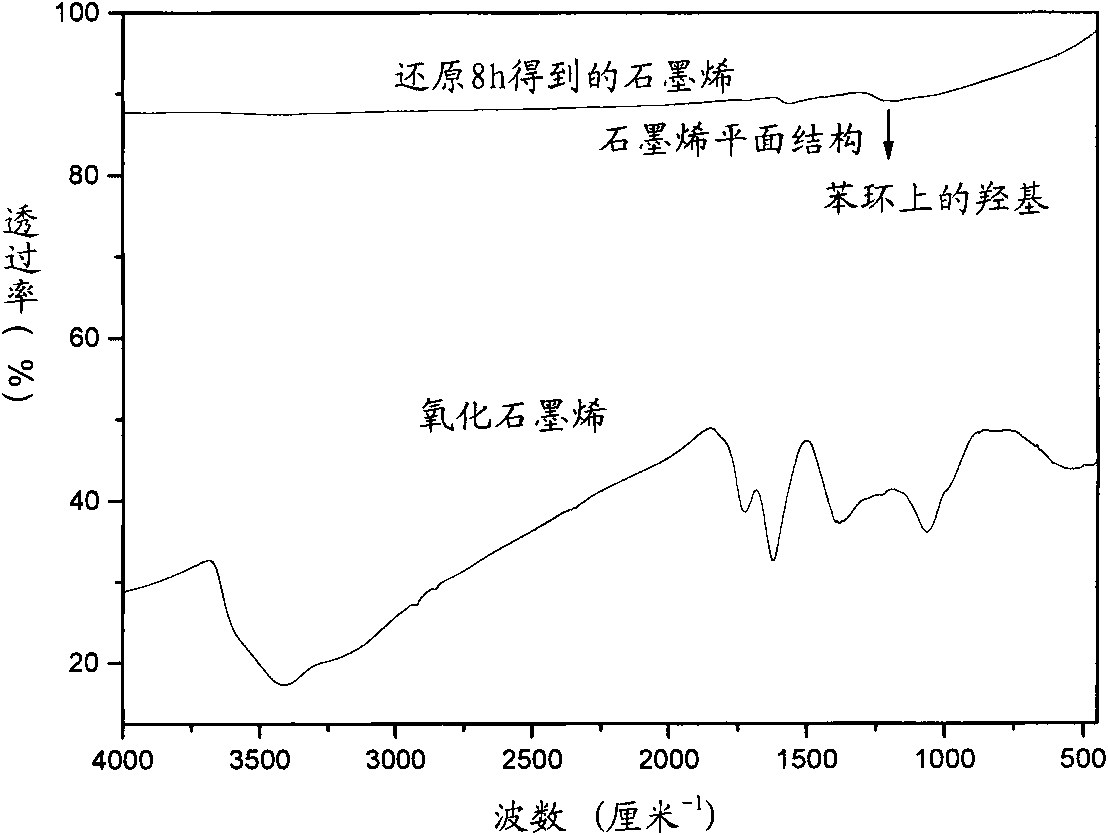

[0048] (1) Preparation of graphene oxide: Preparation of graphene oxide: Take about 1 g of natural flake graphite, add 20 g of concentrated sulfuric acid, stir overnight in an ice bath, add 0.15 g of potassium permanganate to prevent the temperature from rising, and stir after adding 30 minutes, then add 3 grams of potassium permanganate, control the temperature below 20 degrees, raise the temperature to 35 degrees, and keep this temperature for 30 minutes, during this process the solution becomes viscous, add 45 milliliters of water and prevent bubbling, And raise the temperature to 90-95 ° C, maintain this temperature for 15 minutes, then add 30 ml of 30% hydrogen peroxide, add 26 ml of water after stirring for 30 minutes, filter while it is hot, wash 3 times with 50 ml of 3% hydrochloric acid, and filter cake Sonicate 400 ml of water for 1 hour, centri...

Embodiment 2

[0050] Example 2 : Palladium chloride as a catalyst to catalyze the hydrogenation of graphene oxide to prepare graphene

[0051] (1) Preparation of graphene oxide: refer to embodiment 1 step (1);

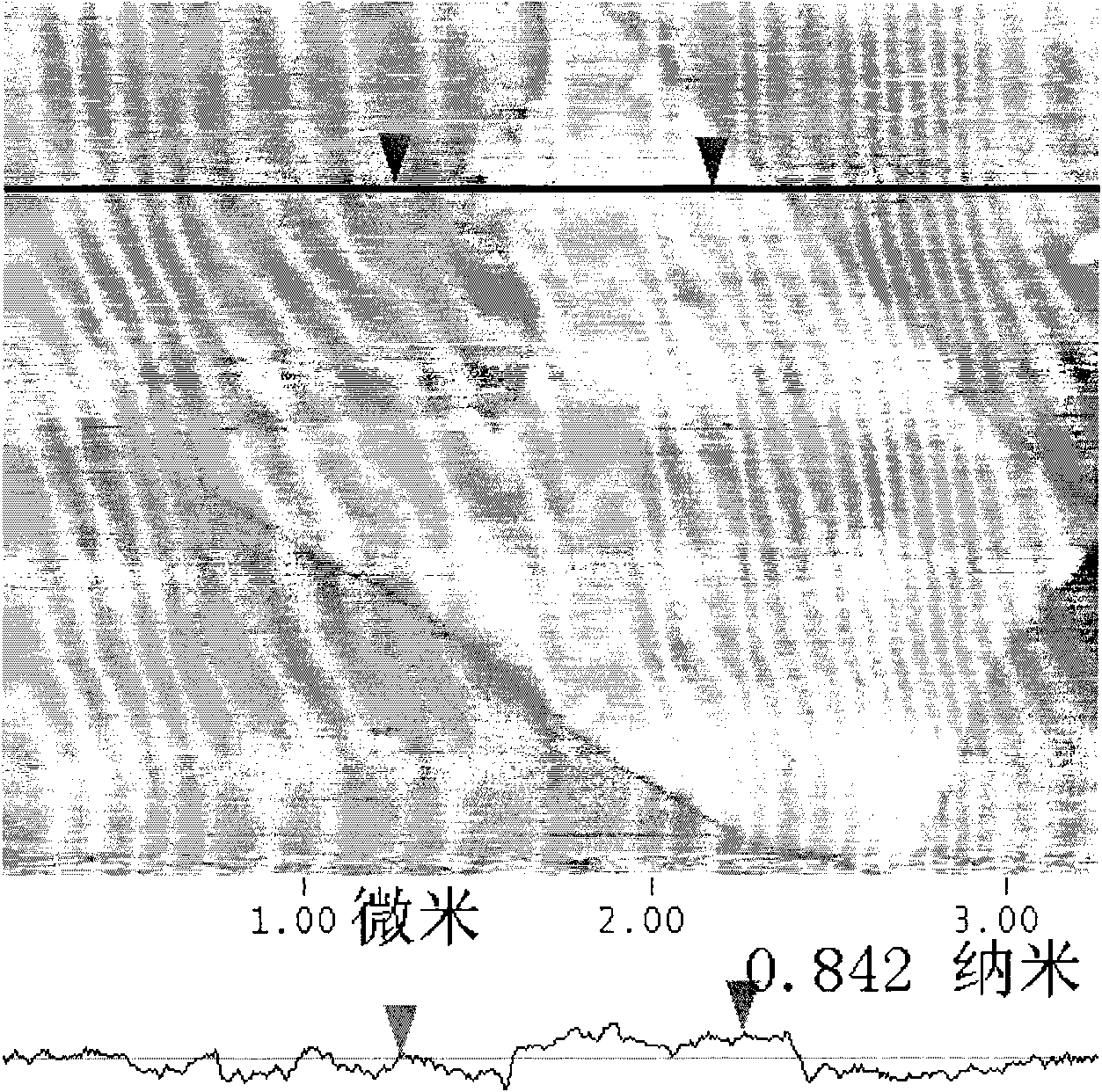

[0052] (2) Preparation of Graphene: Get 60 milliliters of the above-mentioned graphene oxide solution (which contains about 60 mg of graphene oxide), add 1 milliliter of palladium chloride aqueous solution (2g / l, calculated as palladium), and place under high pressure at 25°C React for 20 hours under 5MPa hydrogen pressure in the kettle to obtain graphene. The electron micrograph of this example gained graphene (see Figure 4 ) shows that the obtained graphene exists independently, and electron diffraction photos show that it is a single-layer graphene structure (see Figure 5 ). Among them, the evaluation standard of single-layer graphene is that the brightness of the outer ring is the same as the brightness of the inner ring in the electron diffraction photo. If the brightness...

Embodiment 3

[0054] Example 3 : Palladium chloride as a catalyst to catalyze the hydrogenation of graphene oxide to prepare graphene

[0055] (1) Preparation of graphene oxide: refer to embodiment 1 step (1);

[0056] (2) Preparation of graphene: get 60 milliliters of the solution of above-mentioned graphene oxide (wherein approximately contain 60 milligrams of graphene oxide), micropipette gun takes palladium chloride aqueous solution (2g / l, counts as palladium) 0.05 milliliters and joins in The above solution was reacted for 10,000 h in an autoclave under 0.2 MPa hydrogen pressure at 200° C. to obtain graphene. The ratio of metal atoms to carbon atoms in this example is about 0.0001.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com