Preparation method of gasoline extraction and desulfurization agent

A desulfurization agent and extraction technology, which is applied in the field of preparation of gasoline extraction desulfurization agent, can solve the problems of difficult to achieve industrialization and poor desulfurization effect, and achieve the effects of low cost, stable air and water, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

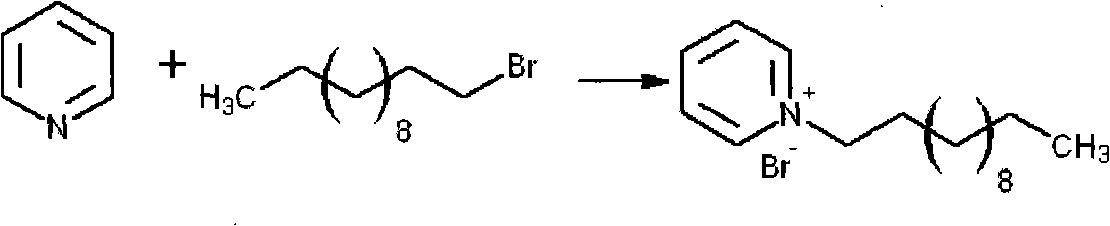

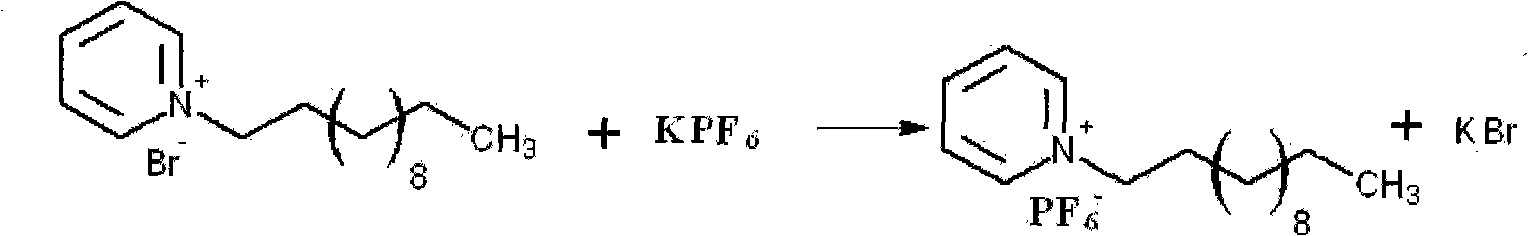

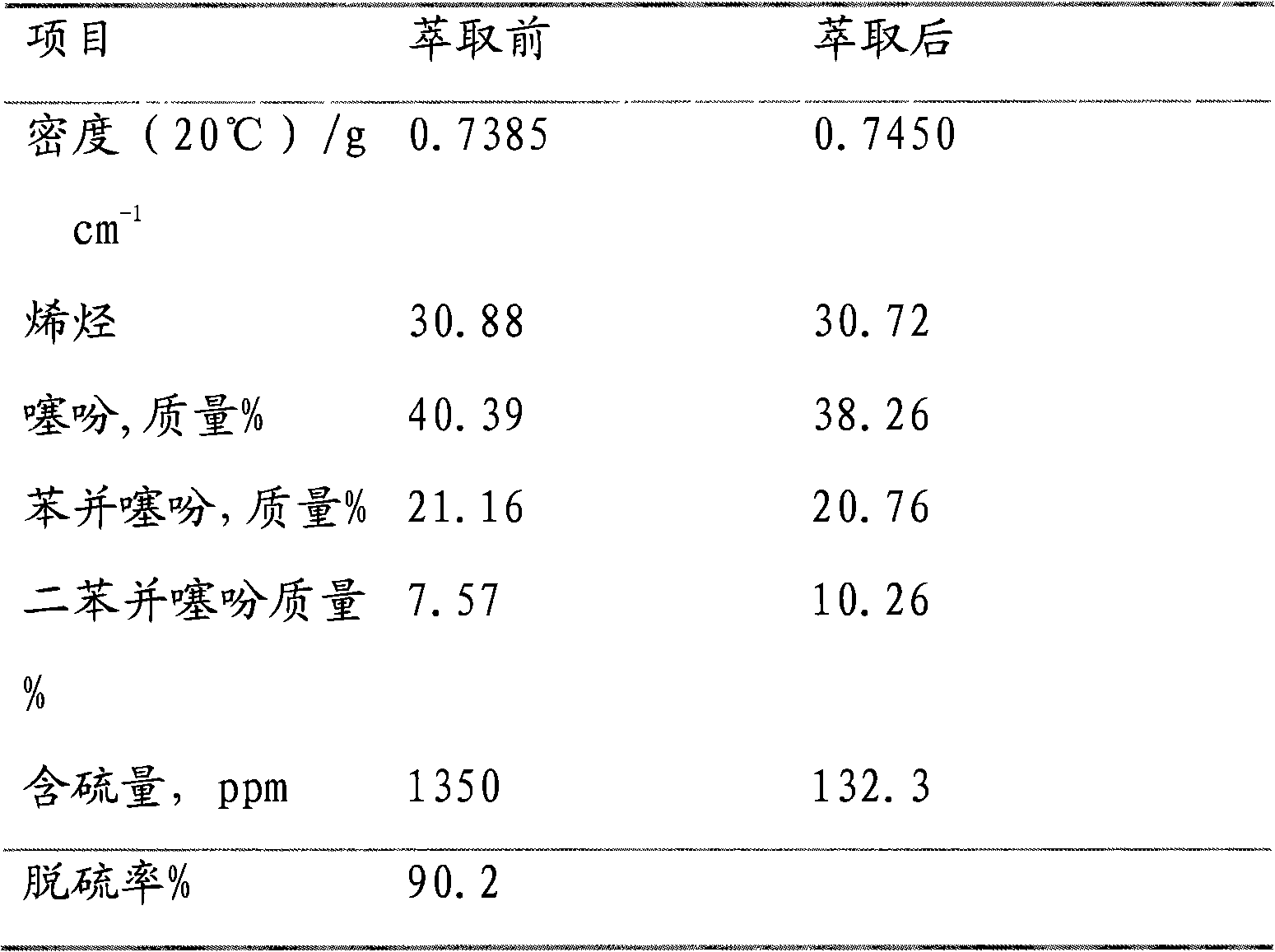

[0018] Add 0.30 mol of pyridine, 0.18 mol of bromododecane and 40 ml of toluene into a closed Erlenmeyer flask, and react at room temperature for 10 h. After the reaction was completed, the residual solvent and unreacted raw materials were distilled off under reduced pressure, washed twice with ethyl acetate, and dried in vacuo to obtain a white solid. Take 0.3mol-dodecylpyridinium bromide and 0.35mol potassium hexafluorophosphate, add 300ml acetone into a round-bottomed flask, stir at room temperature for 10 hours, after standing still, the reaction solution separates into two phases, pour out the light phase, and repeat with distilled water After washing the heavy phase and separating the liquids, the heavy phase is vacuum-dried to a constant weight to remove water, and the light yellow product N-dodecylpyridinium hexafluorophosphate is finally obtained. According to the mass ratio of 3:1, the gasoline model and ionic liquid with a sulfur content of 1350 μg / g were stirred on...

Embodiment 2

[0022]Add 0.30 mol of pyridine, 0.36 mol of bromododecane and 80 ml of toluene into a closed Erlenmeyer flask, and react at room temperature for 24 hours. After the reaction was completed, the residual solvent and unreacted raw materials were distilled off under reduced pressure, washed twice with ethyl acetate, and dried in vacuo to obtain a white solid. Take 0.3 mol of dodecylpyridinium bromide and 0.36 mol of potassium hexafluorophosphate, add 300 ml of acetone into a round bottom flask, stir at room temperature for 15 hours, after standing still, the reaction solution separates into two phases, pour out the light phase, and repeat the process with distilled water. After washing the heavy phase and separating the liquids, the heavy phase is vacuum-dried to a constant weight to remove water, and the light yellow product N-dodecylpyridinium hexafluorophosphate is finally obtained. According to the mass ratio of 3:1, the gasoline model and ionic liquid with a sulfur content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com