Method for extracting capsorubin and capsaicin from chillies

A technology for capsanthin and capsaicin is applied in the field of extracting capsanthin and capsaicin from capsicum, which can solve the problems of increased energy consumption, odorous solvent, long extraction period and the like, and achieves reduced cost and energy consumption, low temperature and high efficiency extraction, The effect of protecting biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

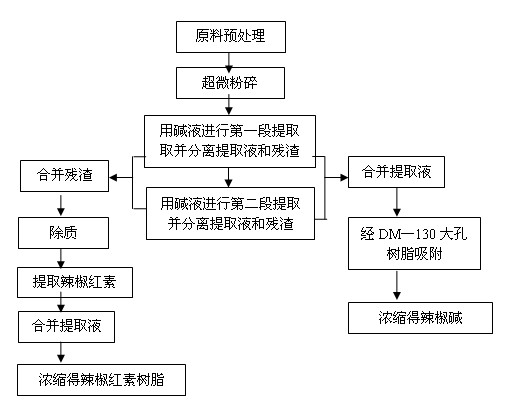

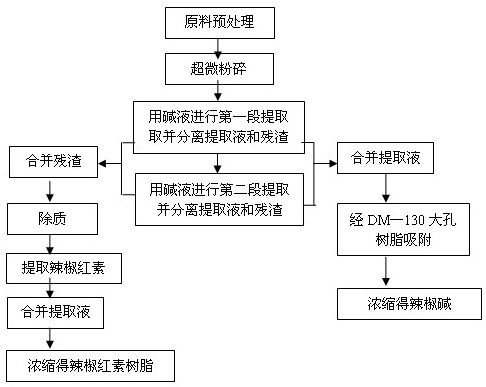

[0031] Example 1 A method for extracting capsanthin and capsaicin from capsicum

[0032] A method for extracting capsanthin and capsaicin from capsicum, comprising:

[0033] 1. Raw material pretreatment: dry the pepper raw material to a dryness with a water content of 4%, separate the skin and seeds, and reserve the pepper skin for later use;

[0034] 2. Pulverization: Superfinely pulverize the chili skin into chili powder;

[0035] 3, extract capsaicin from capsicum powder by solvent method in two stages of gradient extraction:

[0036] The first stage of extraction: using a concentration of 0.03 g / ml Na 2 CO 3 Aqueous solution is used as the extractant, the ratio of solid to liquid is 1g:5ml, and centrifuged after the extraction is completed;

[0037] The second stage of extraction: using a concentration of 0.01 g / mlNa 2 CO 3 The aqueous solution is used as the extraction agent, and the ratio of solid to liquid is 1g: 5ml, and then centrifuged after the extraction is com...

Embodiment 2

[0040] Embodiment 2: A kind of method extracting capsanthin and capsaicin from capsicum

[0041] A method for extracting capsanthin and capsaicin from capsicum, comprising:

[0042] 1. Raw material pretreatment: dry the pepper raw material to a dryness with a water content of 4%, separate the skin and seeds, and reserve the pepper skin for later use;

[0043] 2. Superfine pulverization: Superfine pulverization of pepper skin to a fineness of 150 meshes, and add β-cyclodextrin accounting for 1% of raw material weight during pulverization;

[0044] 3, extract capsaicin from capsicum powder by solvent method in two stages of gradient extraction:

[0045] The first stage of extraction: use NaOH aqueous solution with a concentration of 0.03 g / ml as the extraction agent, the ratio of solid to liquid is 1g:5ml, and centrifuge after the extraction is completed;

[0046] The second stage of extraction: use a NaOH aqueous solution with a concentration of 0.01 g / ml as the extraction ag...

Embodiment 3

[0050] Embodiment 3: A kind of method extracting capsanthin and capsaicin from capsicum

[0051] A method for extracting capsanthin and capsaicin from capsicum, comprising:

[0052] 1. Raw material pretreatment: dry the pepper raw material to a dryness with a water content of 5%, separate the skin and seeds, and reserve the pepper skin for later use;

[0053] 2. Superfine pulverization: superfine pulverization of the pepper skin to a fineness of 200 meshes, adding β-cyclodextrin accounting for 1.5% by weight of raw materials during the pulverization;

[0054] 3, extract capsaicin from capsicum powder by solvent method in two stages of gradient extraction:

[0055] The first stage of extraction: using a concentration of 0.035 g / ml Na 2 SO 3 The aqueous solution is used as the extraction agent, the ratio of solid to liquid is 1g:6ml, the extraction time is 25 minutes, the extraction temperature is 15°C, and centrifugation is carried out after the extraction is completed;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com