Composite superfine fiber wave-absorbing material and preparation method thereof

A wave-absorbing material and ultra-fine fiber technology, which is applied in fiber treatment, chemical instruments and methods, and other chemical processes, can solve problems that are not involved in the preparation method of polyaniline composite ultra-fine fiber wave-absorbing materials, and achieve good mechanical properties , cost saving, easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

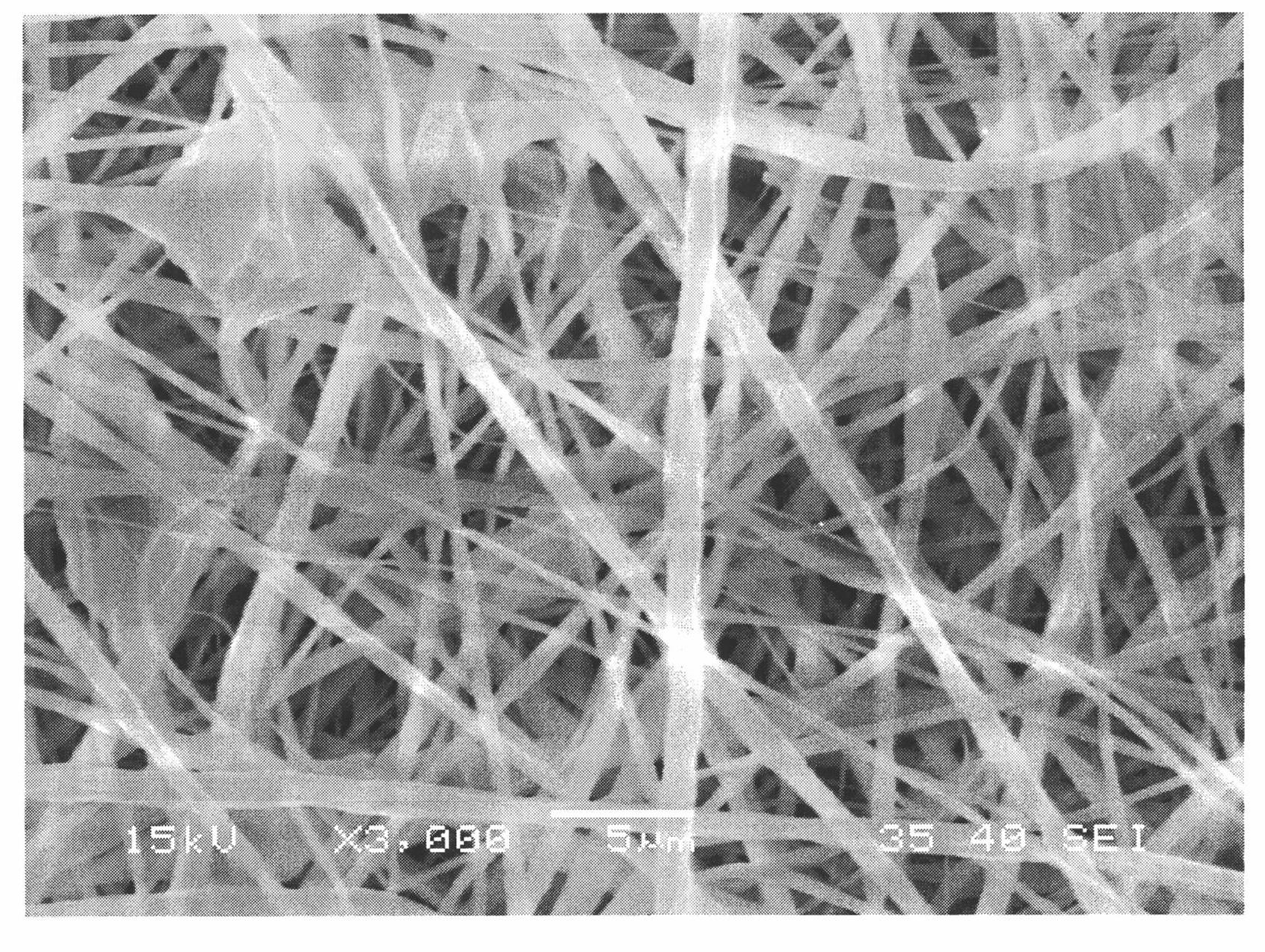

[0017] 0.3mol / l FeSO 4 ·7H 2 O aqueous solution and 0.4mol / L FeCl 3 The aqueous solution is mixed at a volume ratio of 2:1, placed in a three-necked flask with nitrogen, and an appropriate amount of polyethylene glycol is added to it, and the temperature is raised to 70°C after ultrasonic oscillation and mixing, and concentrated ammonia water is added dropwise to it after vigorous stirring for several minutes. , after adjusting to PH=9, continue to react for 1h, magnetically separate the supernatant, and Fe 3 o 4 The particles were washed several times with distilled water and dried under vacuum at 40°C for 24h. Weigh a certain amount of CTAB, mix it with n-butanol according to the mass ratio of 1:1 and place it in a three-necked flask, add 40ml of water to dissolve it, and take the above-mentioned appropriate amount of Fe after nitrogen protection. 3 o 4 The particles were added to the solution, and ultrasonically oscillated for 2 hours at room temperature; 2 ml of anili...

example 2

[0019] 2mol / l FeSO 4 ·7H 2 O aqueous solution and 2.2mol / L FeCl 3 The aqueous solution is mixed with a mass ratio of 3:2, placed in a three-necked flask with nitrogen, and an appropriate amount of polyethylene glycol is added to it, and the temperature is raised to 75°C after ultrasonic oscillation and mixing, and concentrated ammonia water is added dropwise to it after vigorous stirring for several minutes. , after adjusting to PH=9, continue to react for 1.2h, magnetically separate the supernatant, and Fe 3 o 4 The particles were washed several times with distilled water and dried under vacuum at 40°C for 24h. Take a certain amount of CTAB, put it in a three-necked flask after mixing it with n-butanol according to the mass ratio of 3:2, add 80ml of water to dissolve it, and take the above-mentioned appropriate amount of Fe after nitrogen protection. 3 o 4 Particles were added to the solution; and ultrasonically oscillated at room temperature for 2 h. After adding 10 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com