Preparation method of proton exchange membrane fuel cell catalyst

A proton exchange membrane, fuel cell technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of increasing interaction and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

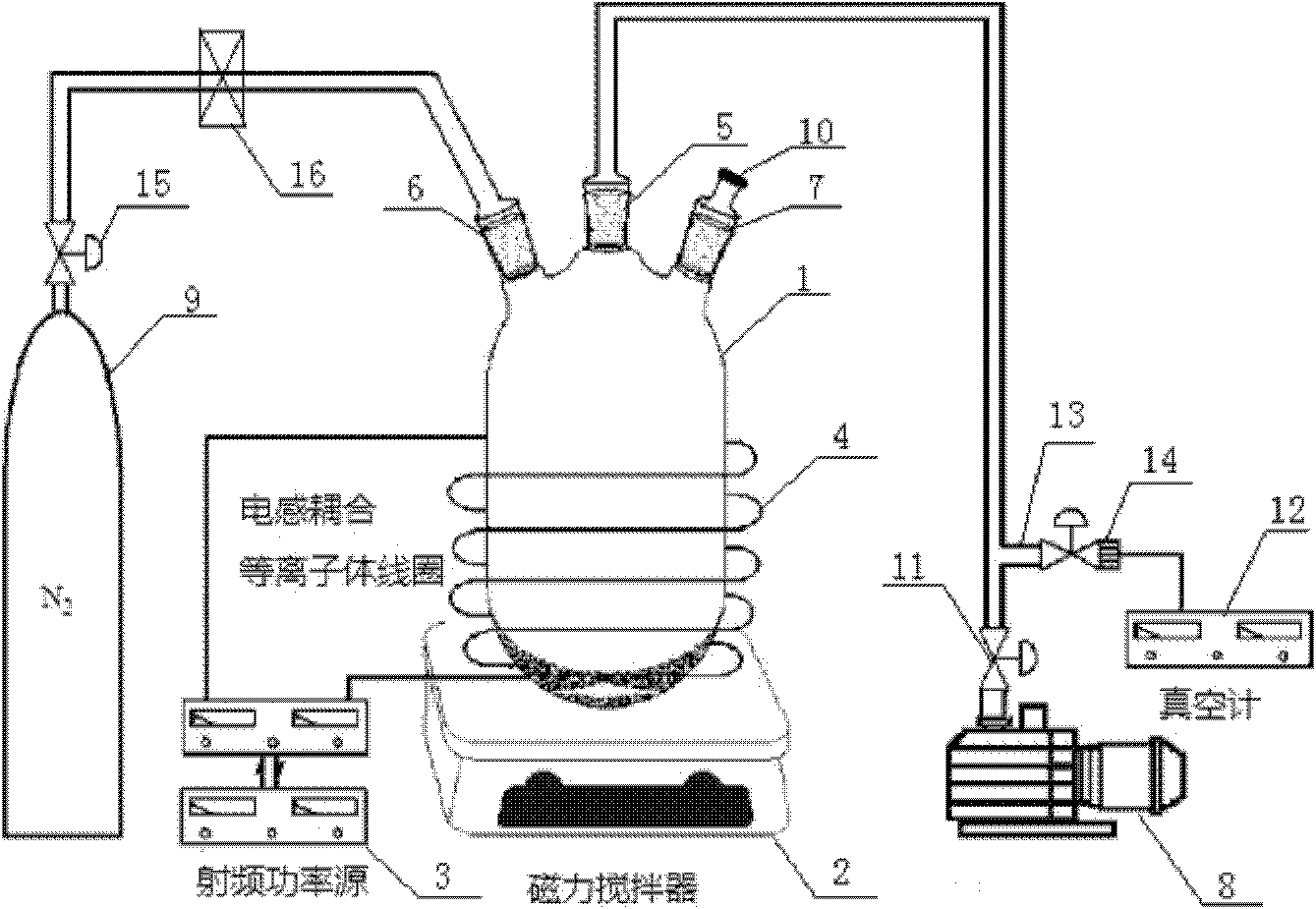

Method used

Image

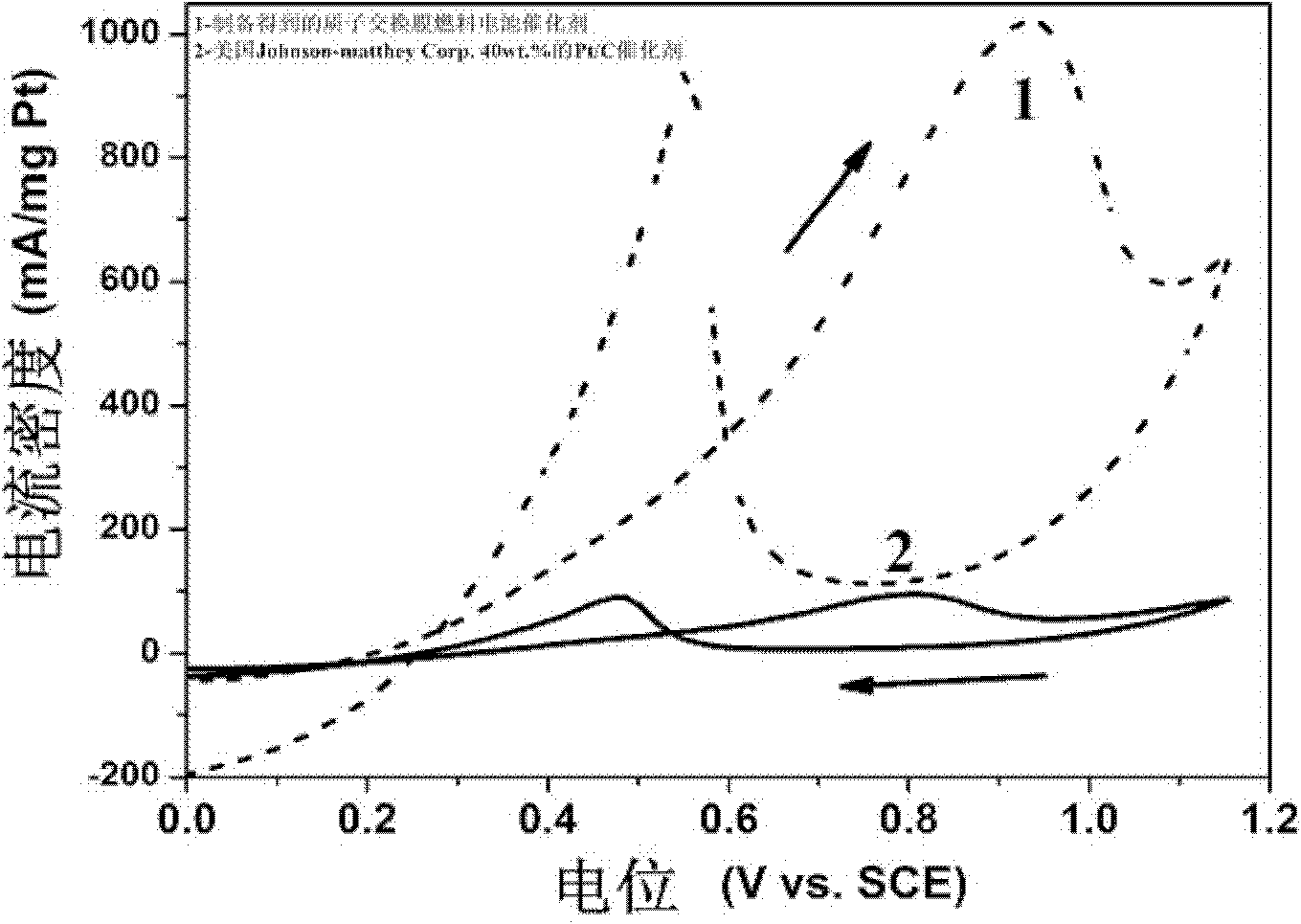

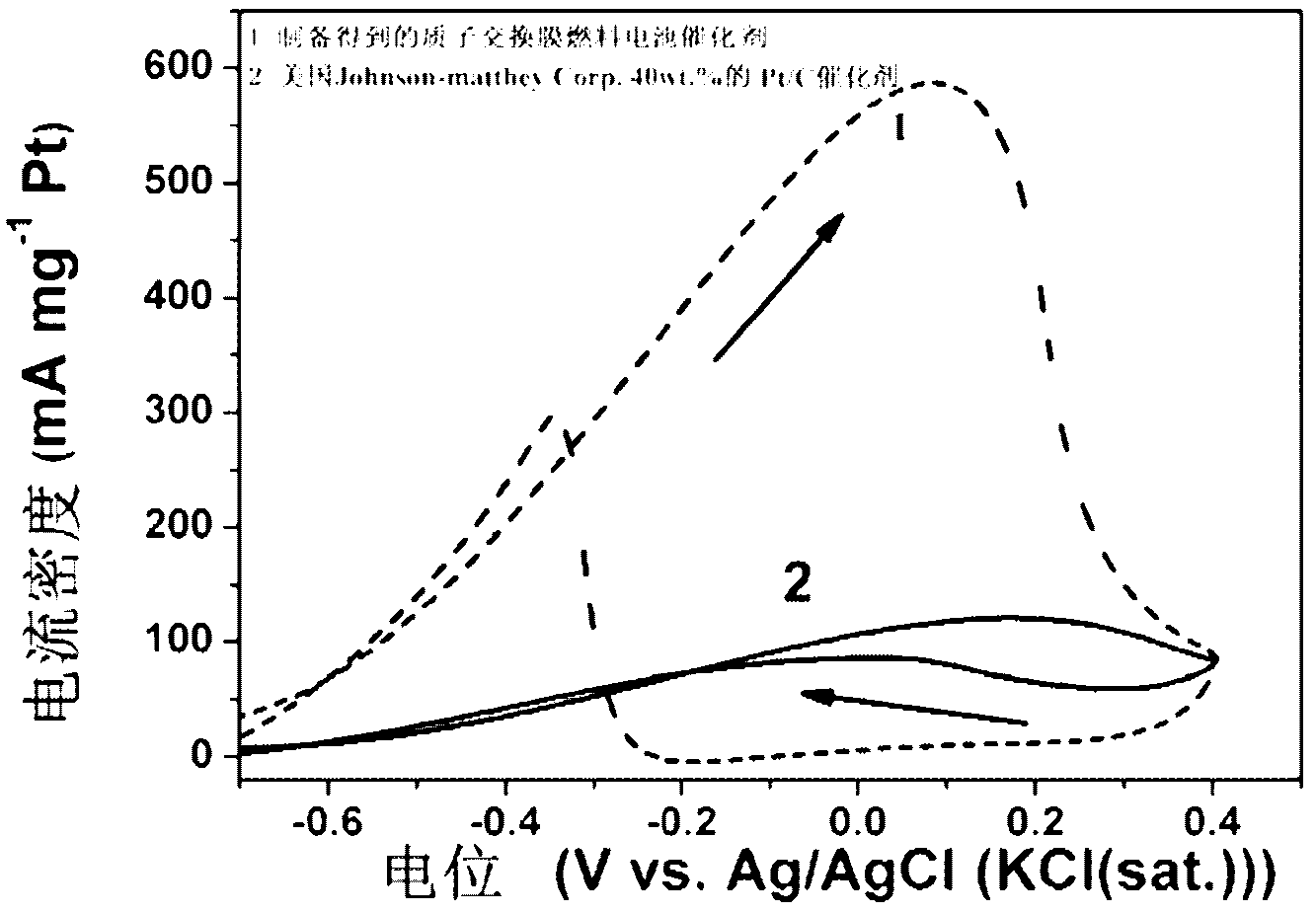

Examples

Embodiment 1

[0037] A kind of preparation method of proton exchange membrane fuel cell catalyst of the present invention comprises the following steps:

[0038] (1) Purification of multi-walled carbon nanotubes (MWCNTs)

[0039] The raw material multi-walled carbon nanotubes (MWCNTs) (Shenzhen Nanoport Co., Ltd., with a diameter of about 20-40nm) at 120 o C conditions, through concentrated HNO 3 Reflux for 3 hours, then wash with distilled water until the pH value is 6-7, filter off the liquid, and then wash at 80 o C under the condition of vacuum drying for 12 h, the multi-walled carbon nanotubes obtained after vacuum drying were placed in a muffle furnace, filled with inert gas argon Ar, at 300 o Under the condition of C, calcining 3h, remove carbon nanoparticle and carbon-containing impurity, obtain the multi-walled carbon nanotube of purification, wherein the mass percentage content of Ni in the multi-walled carbon nanotube after the purification of gained is lower than 0.01%, Fe Th...

Embodiment 2

[0047] A kind of preparation method of proton exchange membrane fuel cell catalyst of the present invention comprises the following steps:

[0048] (1) Purification of carbon nanosheets / walls (CNS / Ws)

[0049] Raw carbon nanosheets / walls (CNS / Ws) at 150 o C conditions, through concentrated HNO 3 Reflux treatment for 5h, then wash with distilled water until the pH value is 6-7, vacuum filter the washed carbon nanosheets / walls to dryness, and then o C under the condition of vacuum drying for 24 h, the carbon nanosheet / wall obtained after vacuum drying is placed in a muffle furnace, filled with inert gas argon Ar, at 600 o Under the condition of C, calcining for 5h, remove carbon nanoparticles and carbon-containing impurities, obtain purified carbon nanosheets / walls, wherein the mass percentage content of Ni in the purified carbon nanosheets / walls obtained is lower than 0.01%, and Fe The mass percentage content is less than 0.03%, of which concentrated HNO 3 The mass fraction...

Embodiment 3

[0061] A kind of preparation method of proton exchange membrane fuel cell catalyst of the present invention comprises the following steps:

[0062] (1) Purification of graphene

[0063] Raw material graphene (Nanjing Pioneer Nanomaterials Technology Co., Ltd.) at 140 o C conditions, through concentrated HNO 3 Reflux treatment for 4h, then wash with distilled water to a pH value of 6-7, vacuum filter the washed graphene to dryness, and then o C under the condition of vacuum drying 20h, the graphene obtained after vacuum drying is placed in the muffle furnace, filled with inert gas argon, at 400 o Under the condition of C, calcining 4h, remove carbon nanoparticle and carbon-containing impurity, obtain the graphene of purification, wherein the mass percentage content of Ni in the graphene after the purification of wherein gained is lower than 0.01%, and the mass percentage content of Fe is lower than 0.03%, of which concentrated HNO 3 The mass fraction concentration is 63%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com