Bacillus subtilis LFB112 as well as bacteriocin produced by same and application thereof

A technology of Bacillus subtilis and LFB112, applied in the field of new strains of Bacillus subtilis and bacteriocin, can solve the problems of limited bacteriostatic spectrum, lack of credible evidence, and no production test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Antibacterial Activity Analysis of Bacillus subtilis LFB112

[0037] Antibacterial activity analysis method: first pour 15ml NA (nutrient agar) solid medium (composition is: 10 grams of peptone, 5 grams of beef extract, 5 grams of sodium chloride, 15 grams of agar, 1000 ml of distilled water, pH7. 0) Make a nutrient agar plate. Then, mix the pathogenic indicator bacteria Staphylococcus aureus CVCC1885 (China Veterinary Microbial Strain Collection Center) cultured overnight with NA (Nutritional Soft Agar) medium (containing 0.75% agar, w / v), and make it into The concentration of indicator bacteria was diluted by 10 6 About cfu / ml, take 5ml and pour it into the prepared nutrient agar plate. Place the Oxford cup gently on the plate, add 100 μl of centrifuged supernatant to the Oxford cup and let it stand at 4°C for 2 hours, then culture at 37°C for 18 hours to observe the appearance of the inhibition zone. Determination of the antibacterial activity unit of ba...

Embodiment 2

[0046] Example 2 Preparation of bacteriocin

[0047] 1. Fermentation culture

[0048] The best medium for producing bacteriocin by Bacillus subtilis LFB112 fermentation is the improved BPY medium, and its ingredients are: 20 grams of peptone, 10 grams of glucose, 10 grams of yeast extract, 10 grams of beef extract, 3 grams of salt, 2.5 dipotassium hydrogen phosphate gram, distilled water 1000ml, pH value 7.2, at 37 ℃, 120 rpm shaker fermentation for 24 hours.

[0049] 2. Separation of crude bacteriocin

[0050] Centrifuge the fermentation broth at 10,000 rpm for 15 minutes, then take the supernatant, slowly add ammonium sulfate solid powder to the supernatant for salting out, stir while adding, until the saturation reaches 80%, and then incubate at 4°C Let stand for 12 hours, then centrifuge at 12,000 rpm at 4°C for 30 minutes, discard the supernatant to obtain the crude precipitated bacteriocin.

[0051] 3. Purification

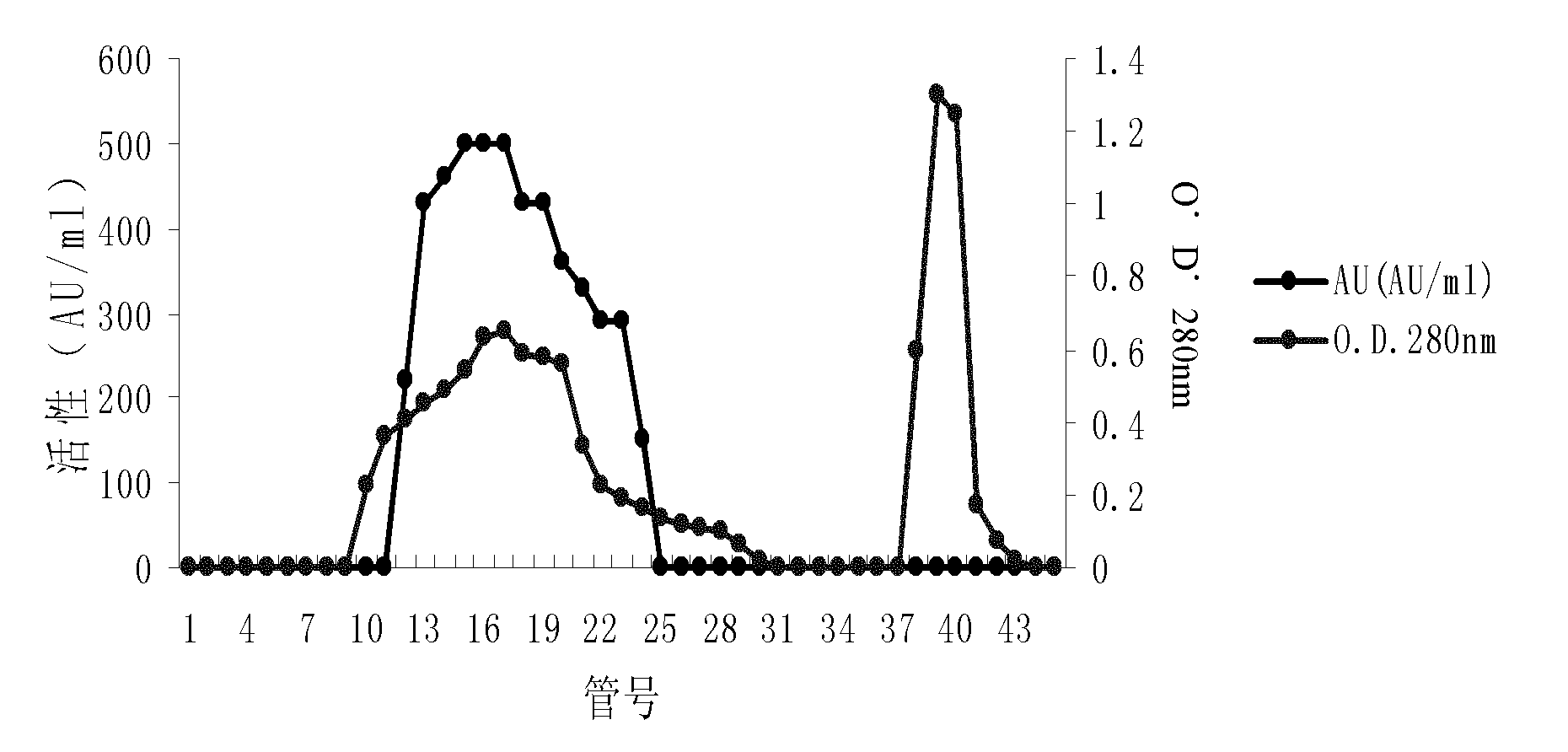

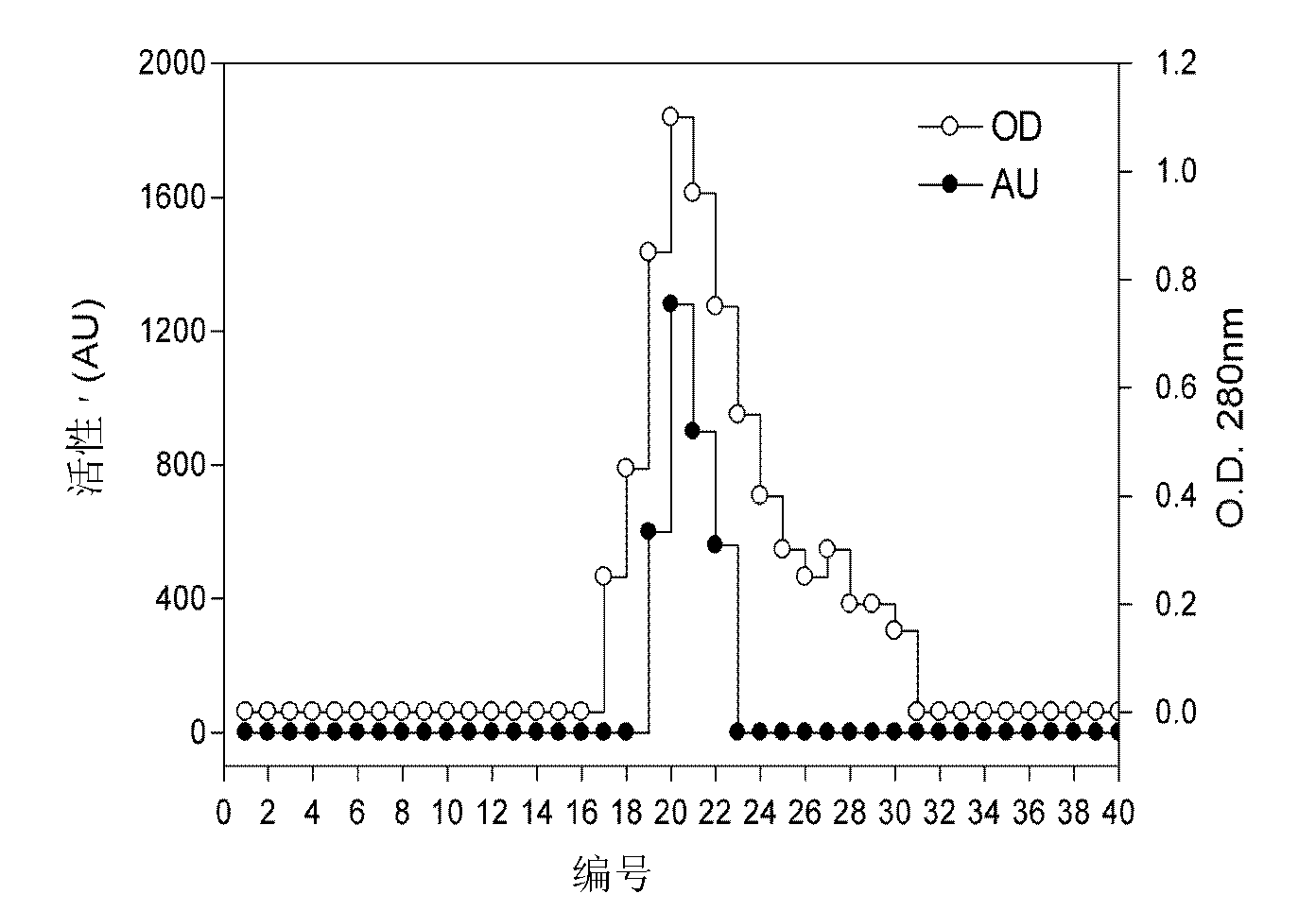

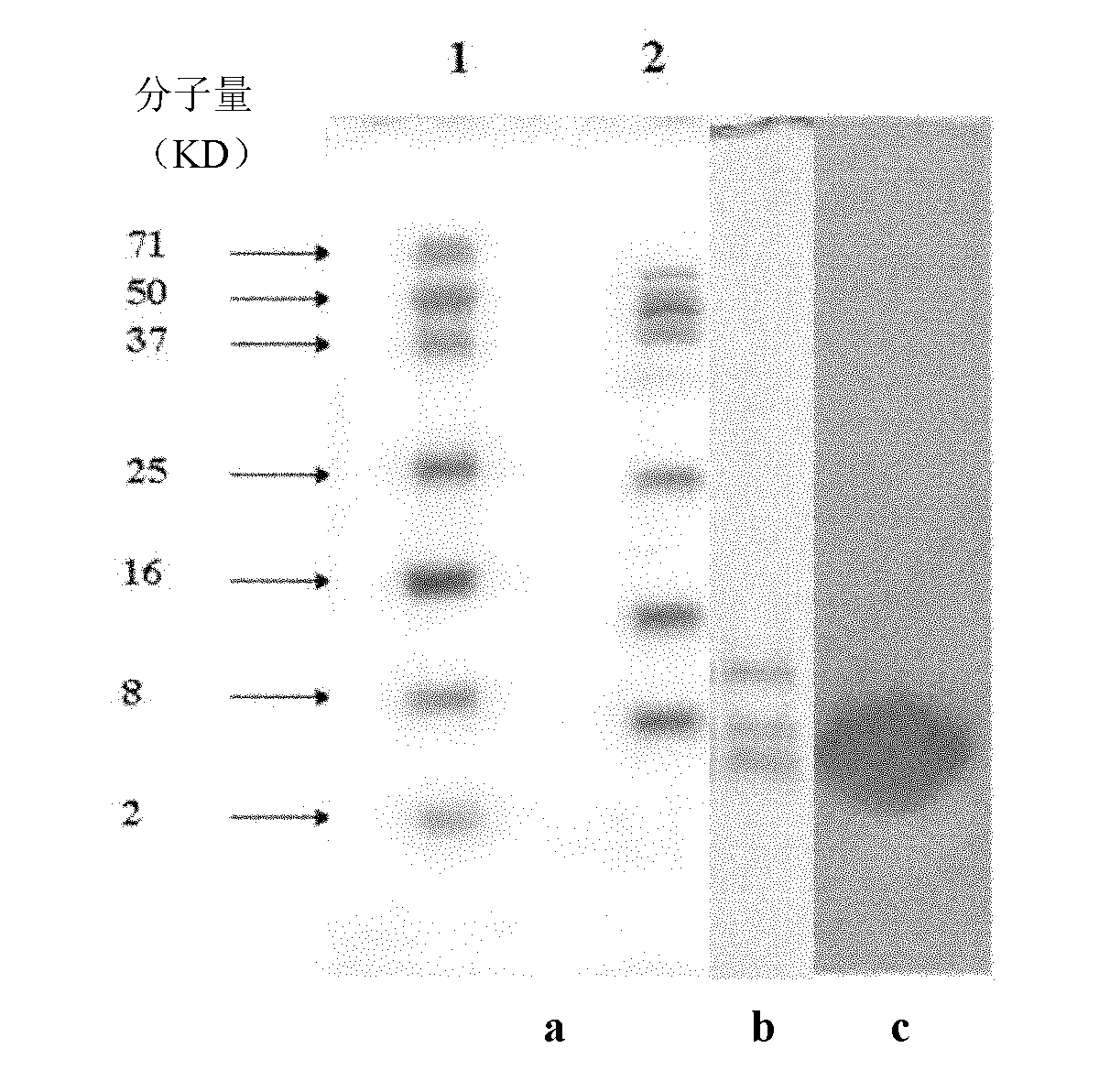

[0052] A certain volume of 20 mM phosphate buffer ...

Embodiment 3

[0054] The bacteriostatic spectrum of embodiment 3 bacteriocin

[0055] Test strains:

[0056] Escherichia coli: Escherichia coli CVCC195, Escherichia coli CVCC249, Escherichia coli CVCC247, Escherichia coli CVCC8099, Escherichia coli CVCC245, Escherichia coli CVCC232, Escherichia coli CVCC1498, Escherichia coli CVCC1158, drug-resistant Escherichia coli F015

[0057] Salmonella: Salmonella CVCC79301, Salmonella C79-52, Salmonella typhimurium CVCC541, drug-resistant Salmonella E103

[0058] Staphylococcus aureus: Staphylococcus aureus CVCC1885, Staphylococcus aureus CVCC6538, Staphylococcus aureus 1882,

[0059] Enterococcus: Enterococcus faecalis 1.130, Enterococcus faecalis 1.595, Enterococcus faecalis 1.2025.

[0060] Pseudomonas: Pseudomonas aeruginosa CVCC2087, Pseudomonas aeruginosa CVCC2088.

[0061] Micrococcus luteus: Micrococcus luteus 1600

[0062] Listeria: Listeria monocytogenes 54002, Listeria monocytogenes 1599

[0063] Streptococcus: Streptococcus lactis CI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com