Method for preparing ethylenediamine modified chitosan composite magnetic microspheres and application thereof

A composite magnetic and chitosan technology, applied in magnetic liquids, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of difficult separation and recovery of adsorbents, reduction of chitosan adsorption sites, and reduced adsorption capacity, etc. Achieving good adsorption effect, good regeneration performance and extremely high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

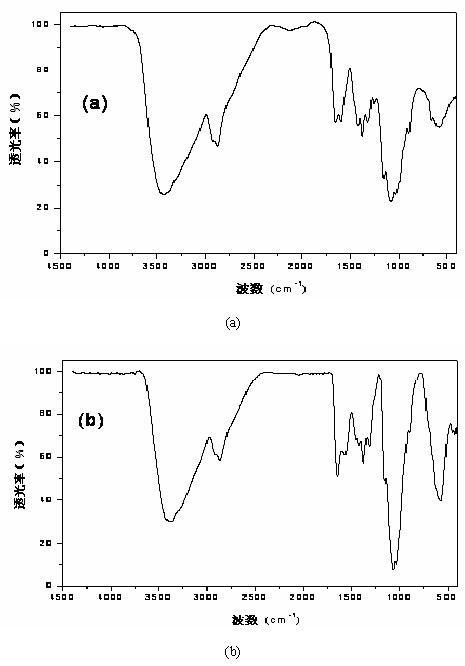

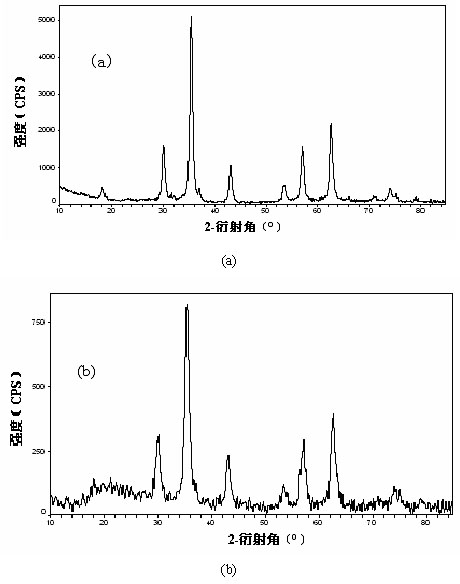

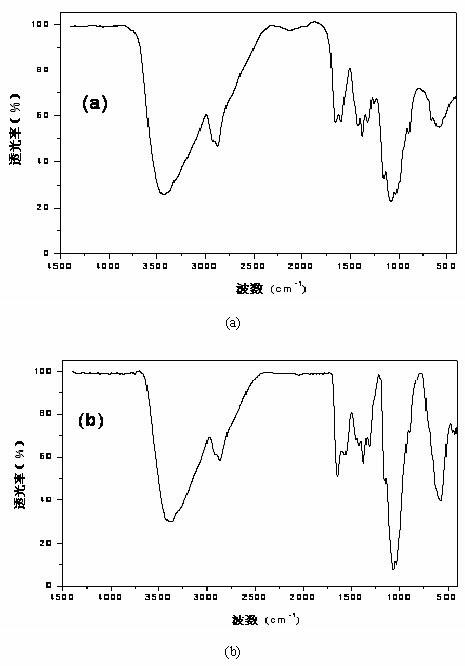

Image

Examples

Embodiment 1

[0032] Weigh 40.55g of ferric chloride (or ferric sulfate and ferric nitrate of the same molar mass) to dissolve and set the volume to a 250ml volumetric flask; weigh 27.802g of ferrous sulfate heptahydrate (or ferrous sulfate monohydrate of the same molar mass, (ferrous chloride) dissolved in a 250ml volumetric flask; mix 240ml ferric chloride solution and 240ml ferrous sulfate heptahydrate solution in a 1L beaker, put the beaker in a water bath, and the temperature of the water bath is 55°C. Then adjust pH=9, stir at constant temperature (55°C) (speed 1000r / min) for 10 minutes to ensure complete reaction; raise the temperature of the water bath to 65°C, add 0.5~3ml sodium dodecylsulfonate solution (or Tween, ten Sodium hexaalkylbenzene sulfonate, sodium hexadecyl sulfate), stir for 30min; adjust pH=7 with 5% HCl; wash with water 3 times, and set the volume to about 400ml; vibrate in an ultrasonic disperser for 40min; get a concentration of about 20g / L of water-based ferrofl...

Embodiment 2

[0037]Take 100 mL of U(VI) solution with an initial concentration of 10-200 mg / L, adjust the pH to 2.5-5.5, add 0.2 g of the magnetic microspheres obtained in Example 1, and react for 20 min. After the microspheres are magnetically separated, the residual The concentration of uranium was determined by spectrophotometry, and the adsorption and removal rate of uranium was 96.7±3.1%.

Embodiment 3

[0039] Take 100 mL of Cr(VI) solution with an initial concentration of 10-200 mg / L, adjust the pH to 3.0-6.0, add 0.2 g of the magnetic microspheres obtained in Example 1, and react for 20 min. After the microspheres are magnetically separated, the residual The concentration of chromium was measured by spectrophotometry, and the adsorption and removal rate of chromium was 97.4±2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com