Thermal wind sensor based on anodic bonding technology and preparation method thereof

A technology of anodic bonding and wind speed and wind direction, which is applied in the process of producing decorative surface effects, metal material coating process, semiconductor/solid-state device manufacturing, etc., can solve the problem of increasing the sensor, reducing the output sensitive signal amplitude, power consumption Dissipation and other problems to achieve the effect of reducing heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

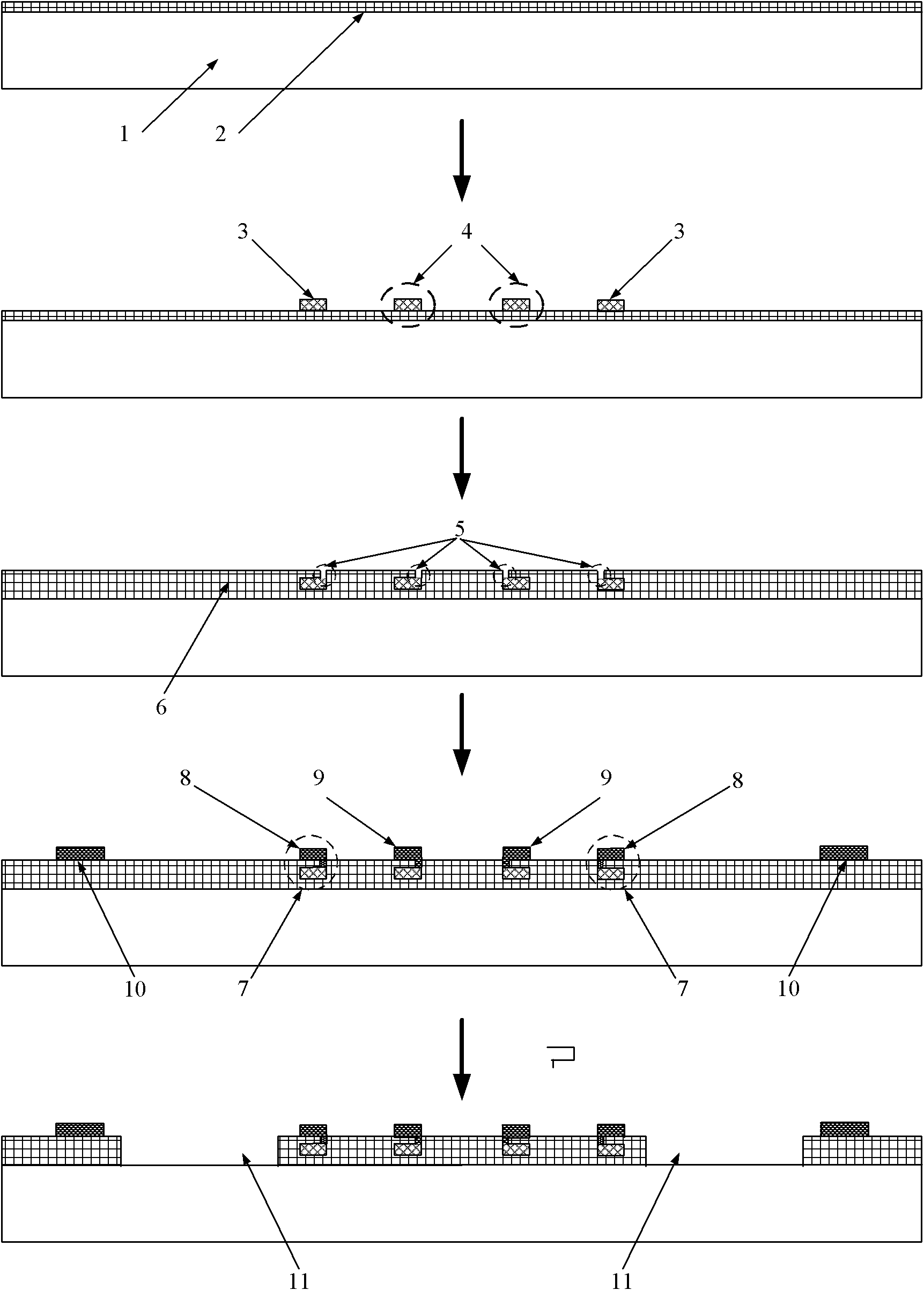

[0039] The manufacturing process of a wafer-level package thermal wind speed and direction sensor based on anodic bonding technology is as follows:

[0040] The first step, the preparation of silicon chips, such as figure 1 shown

[0041] Step 1, thermally growing a first thermal oxide layer 2 on the surface of the silicon chip 1;

[0042] Step 2, preparing the first polysilicon 3 as one end of the heat sensing temperature measuring element 7 on the first thermal oxide layer 2, and the second polysilicon as the polysilicon heating element 4;

[0043] Step 3, chemical vapor deposition of a second oxide layer on the first thermal oxide layer 2, the first polysilicon 3 and the second polysilicon, and forming an oxide layer 6 from the first thermal oxide layer 2 and the second oxide layer , and use an etching process to etch a through hole 5 on the oxide layer above the first polysilicon 3 and the polysilicon heating element 4;

[0044] Step 4, sputtering and patterning metal a...

Embodiment 2

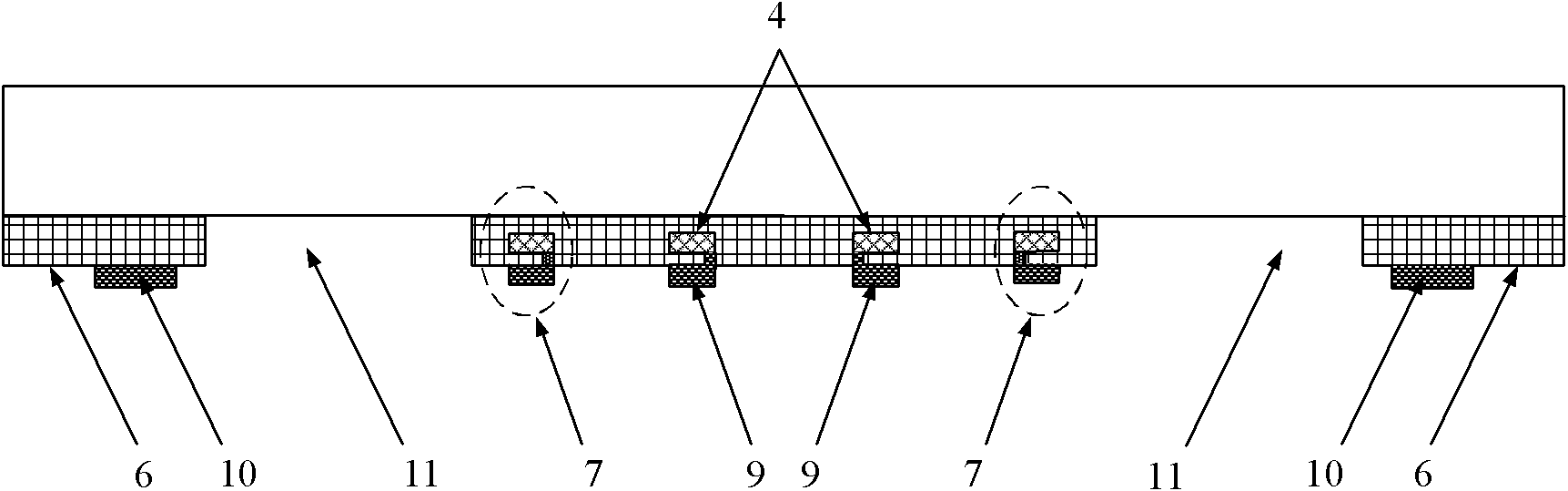

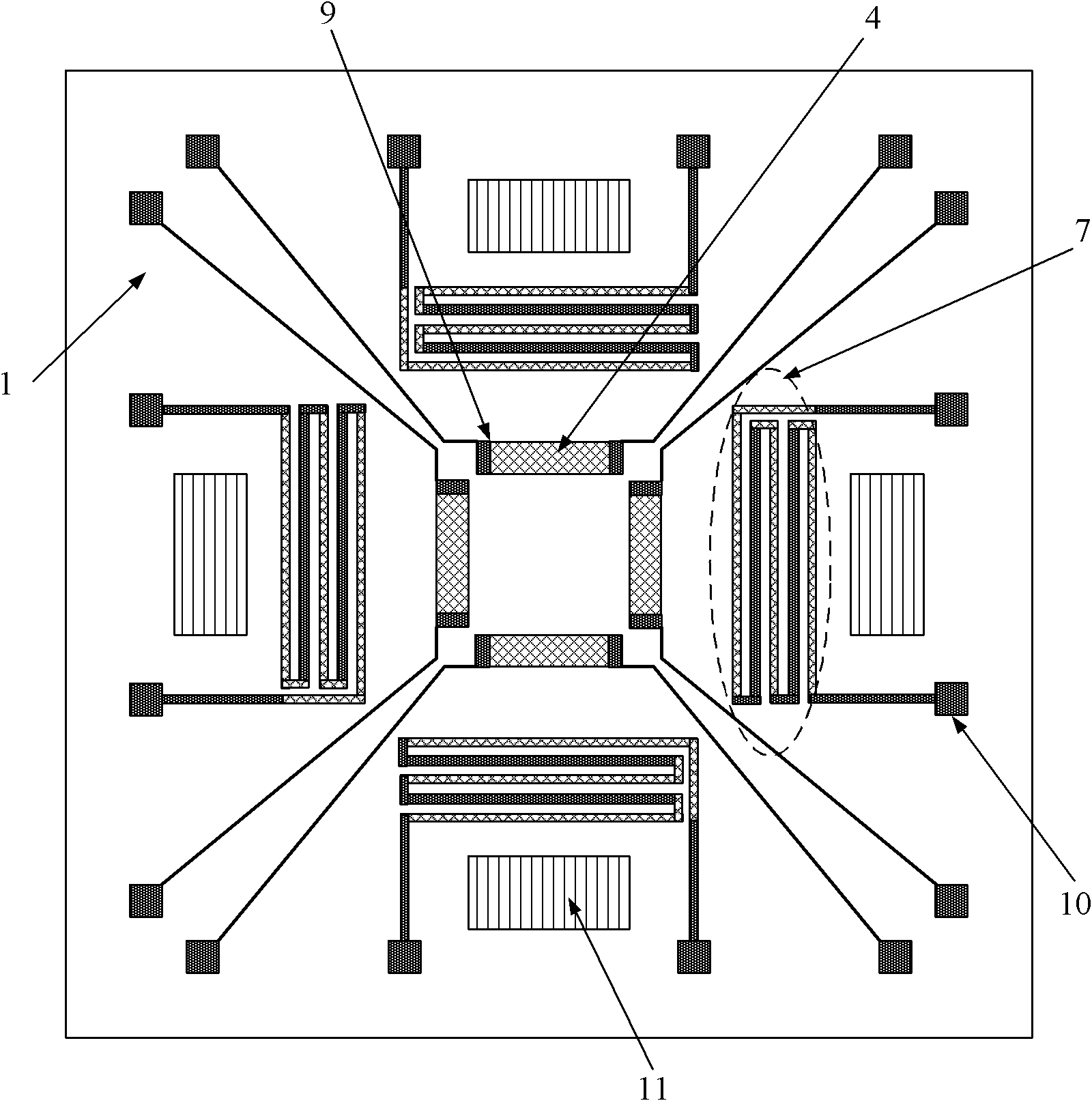

[0058] A thermal wind speed and direction sensor based on the anodic bonding process, comprising a thinned silicon chip 15, the back of the thinned silicon chip 15 is connected with a ceramic sensing substrate 17 through a thermally conductive glue 16, and on the front of the thinned silicon chip 15 An oxide layer 6 is provided, and four polysilicon heating elements 4 and four heat-sensing and temperature-measuring elements 7 are arranged in the middle of the oxide layer 6, and electric lead-out pads 10 are arranged on the edge area of the oxide layer 6, and four polysilicon heating elements are arranged. The element 4 and the four heat-sensing and temperature-measuring elements 7 are respectively connected to the electrical lead-out pad 10 through metal leads. It is characterized in that a bonding cavity 11 capable of exposing a thinned silicon chip 15 is provided on the oxide layer 6. The thinned silicon chip 15 exposed in the bonding cavity 11 is bonded with the packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com