Method for preparing tungsten diselenide nano sheets

A technology of tungsten diselenide and nanosheets, which is applied in the field of preparation of tungsten diselenide nanosheets, to achieve the effects of safety and environmental protection, good dispersion performance and high yield in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

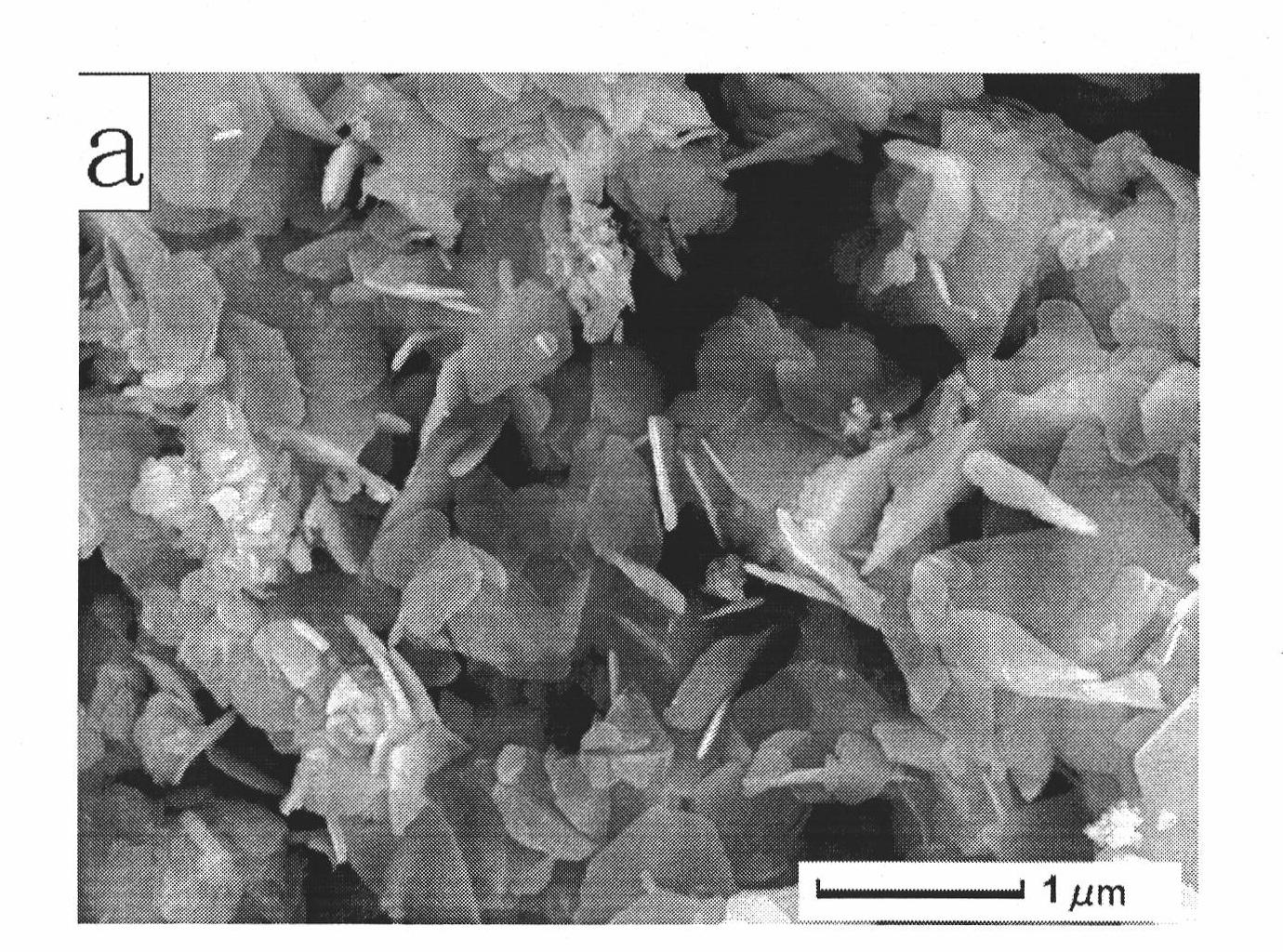

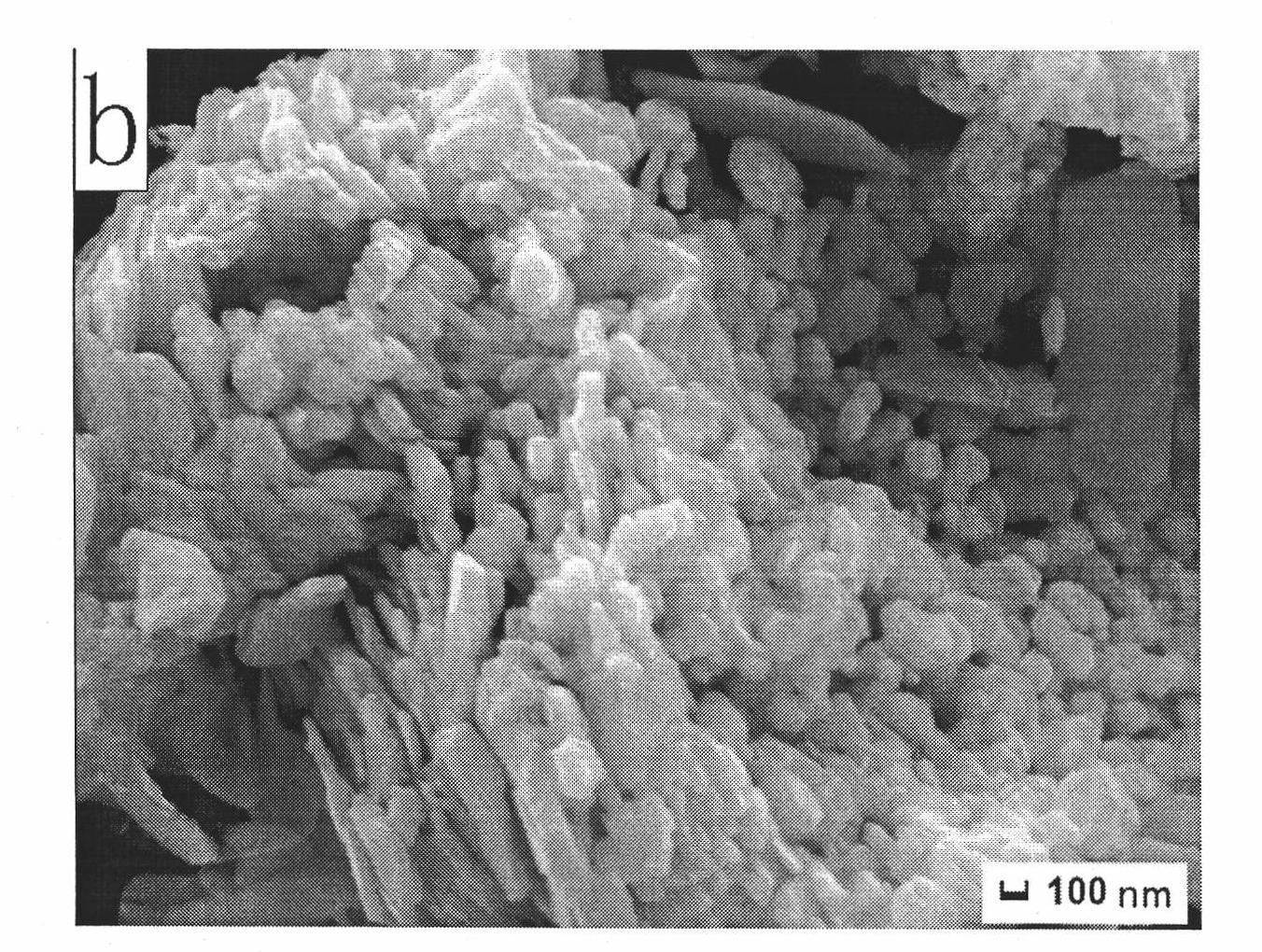

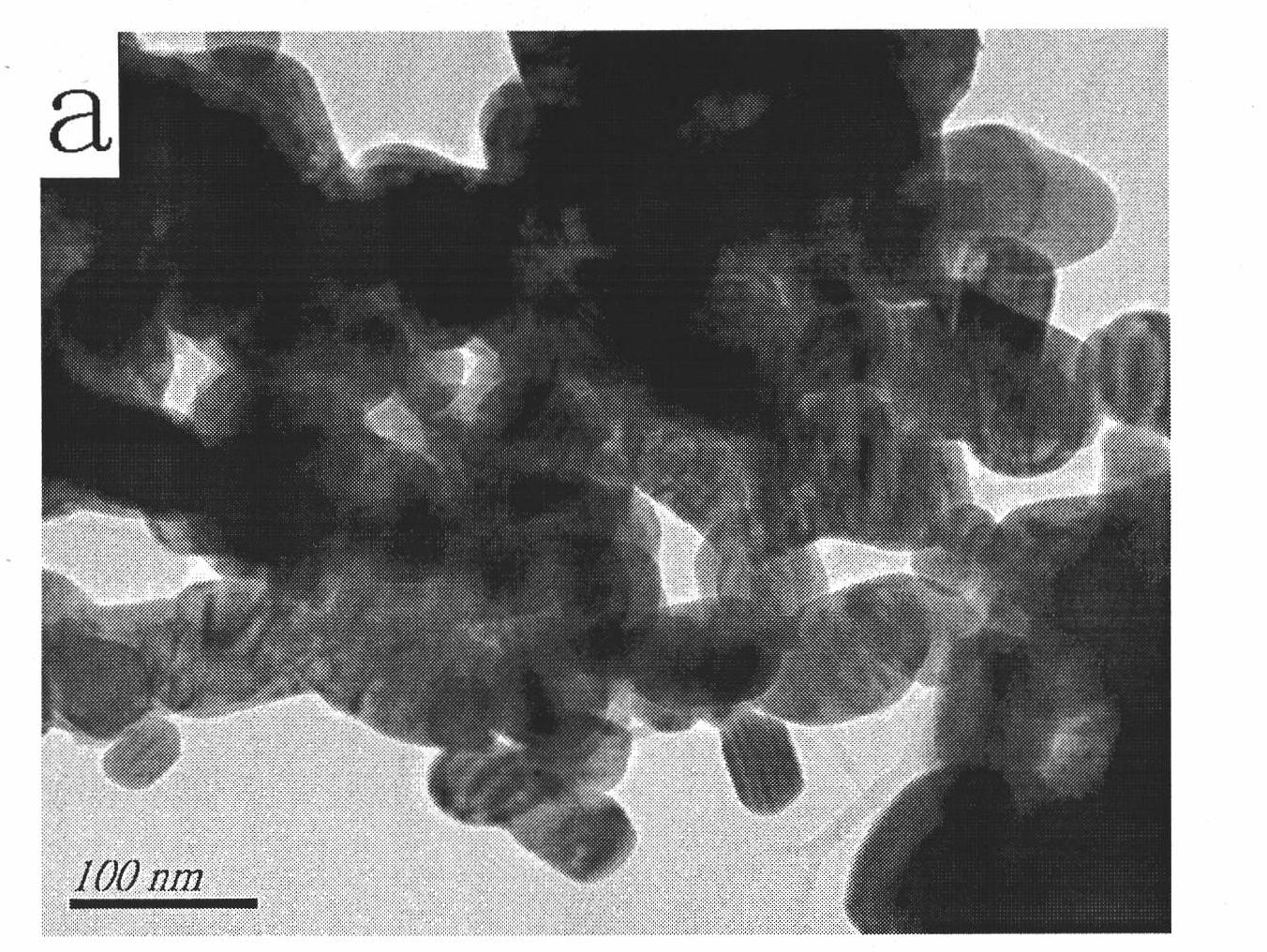

Image

Examples

Embodiment 1

[0017] Prepare tungsten diselenide nanosheets as follows:

[0018] (1) Prepare the raw material mixture: take tungsten powder and selenium powder according to the molar ratio of 1:2, and the selenium powder is excessively 5%. After mixing, grind in a mortar for 5 minutes, and then mix with a stainless steel ball with a diameter of 8mm according to the mass ratio Mix 1:10 into the ball mill jar, seal and extract the air in the jar, repeatedly pass in and extract argon gas for 5 times, put the ball mill jar into the ball mill, and mill the powder in the ball mill jar at a speed of 200 rpm for 30 minutes , Then take out the powder and put it into a quartz glass tube with a diameter of 15mm sealed at one end to obtain a raw material mixture;

[0019] (2) Heating synthesis: heat the above-mentioned quartz tube with an acetylene flame until its open end is in a molten state, then seal it and leave a small hole, connect the small hole with a vacuum pump to vacuum the quartz tube and then ...

Embodiment 2

[0021] Prepare tungsten diselenide nanosheets as follows:

[0022] (1) Prepare the raw material mixture: take tungsten powder and selenium powder according to the molar ratio of 1:2, and the selenium powder is excessively 5%, mix well, grind in a mortar for 5 minutes, and then mix with a stainless steel ball with a diameter of 8mm according to mass ratio Mix 1:10 into the ball mill jar, seal and extract the air in the jar, repeatedly pass in and extract argon gas for 5 times, put the ball mill jar into the ball mill, and mill the powder in the ball mill jar at a speed of 200 rpm for 30 minutes , Then take out the powder and put it into a quartz glass tube with a diameter of 15mm sealed at one end to obtain a raw material mixture;

[0023] (2) Heating synthesis: heat the above-mentioned quartz tube with an acetylene flame until its open end is in a molten state, then seal it and leave a small hole, connect the small hole with a vacuum pump to vacuum the quartz tube and then seal it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com