Pesticide micro-capsule granules and preparation method thereof

A technology of microcapsule granules and microcapsule suspensions, which is applied in the field of pesticide microcapsule granules and its preparation, can solve the problems of reduced decomposition rate of active ingredients, poor storage stability, poor chemical stability, etc. Dosage, good control and prevention effect, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

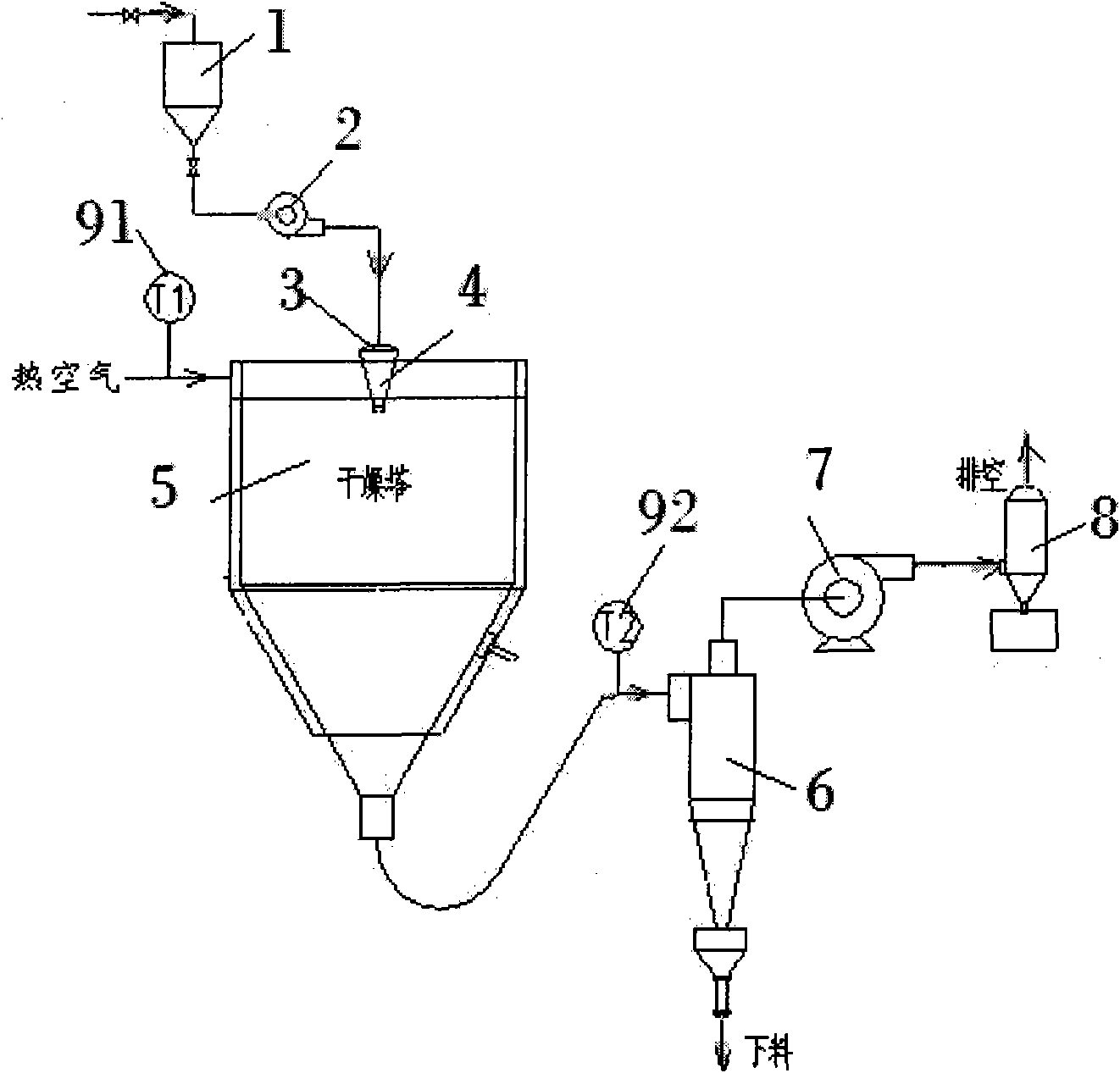

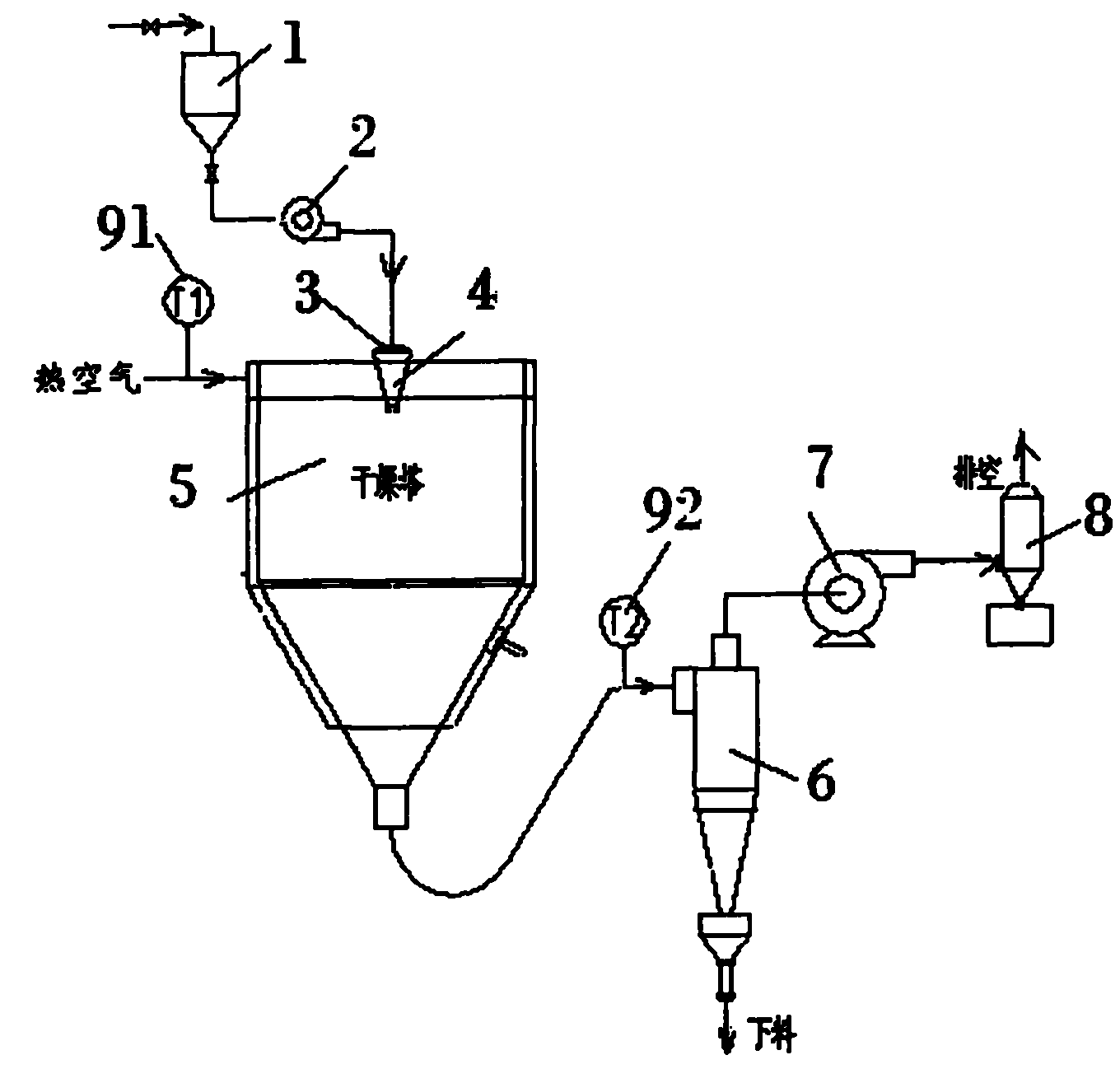

[0066] The first step, the preparation of pesticide microcapsule suspension:

[0067] The existing pesticide microencapsulation technology mainly has three kinds of process routes:

[0068] The first is the route of interfacial polymerization, which usually uses isocyanate (TDI) or prepolymer (MDI) to react with polyamine or polyol to form the capsule shell material of polyurea resin.

[0069] The second one adopts the in-situ polymerization process route, generally adopts urea-formaldehyde prepolymer solution to form capsules, controls the process parameters such as the rate of acid addition, the way of acid addition, the temperature of aging, the speed of solution stirring, etc., and adjusts the pH range , Under the action of catalysis, polycondensation forms strong and impermeable microcapsules.

[0070] The third is the preparation process of complex coacervation. In the aqueous solution mixed with dissolved natural polymer materials (such as gelatin and gum arabic), the ...

Embodiment 1

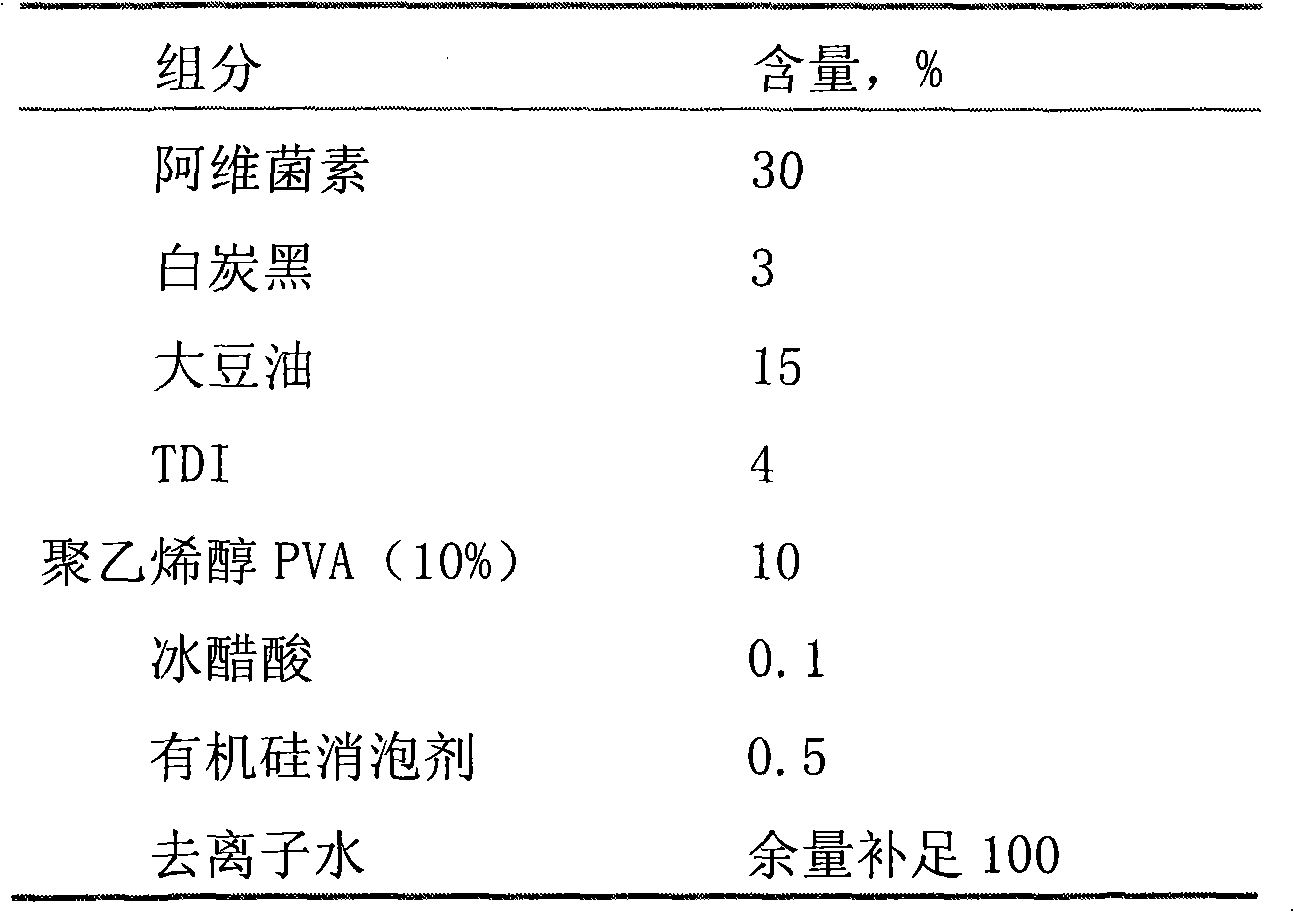

[0085] Embodiment one: the formula component of Abamectin microcapsule suspension

[0086]

[0087] Disperse the former medicine of 30kg of insecticide Abamectin and 3kg of carrier white carbon black in 15kg of soybean oil (commercially available) and stir evenly (oil phase) through a sand mill until the average of the material The particle size reaches 2um~8um, then add 4kg of toluene diisocyanate TDI (Cangzhou Dahua TDI Co., Ltd.) and stir evenly (oil phase); then prepare the water phase: add 10kg of 10% polyvinyl alcohol PVA aqueous solution to 40kg of deionized water Stir well (water phase); put the prepared oil phase material into the water phase and turn on high-speed homogenization to form a stable O / W emulsion; turn on stirring (maintain 800 rpm), and then heat the homogenized emulsion to 70°C, maintain a stable solidification temperature of the capsule wall material for 3 hours, then add 0.1kg of PH regulator glacial acetic acid to adjust the pH value to about 7, a...

Embodiment 2

[0089] Embodiment two, alachlor microcapsule suspension formulation components

[0090]

[0091]The herbicide alachlor of 20kg is heated to molten state, adds the polyphenyl polymethylene polyisocyanate PAPI (Bayer company of Germany) of 2kg and the diphenylmethane diisocyanate MDI of 1kg (Yantai Wanhua Polyurethane Co., Ltd.) Stir evenly (oil phase); add 0.2kg of methylcellulose CMC to 50kg of deionized water, stir evenly (water phase) put the prepared oil phase material into the water phase and start high-speed homogenization to form a stable O / W emulsion; start stirring (maintain 400 rpm / min), then heat up the homogenized emulsion to 40°C, and slowly add 0.5kg of ethylenediamine at the same time to maintain a stable solidification temperature of the capsule wall material for 20 hours, and then add the emulsifier Wet agent NNO 3.0kg (Shanghai Tiantan Auxiliary Factory), dispersant sodium lignosulfonate (produced in Russia) 5.0kg, disintegrant modified starch 1.0kg, white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com