Alginate-epsilon-polylysine microcapsules and preparation and application thereof

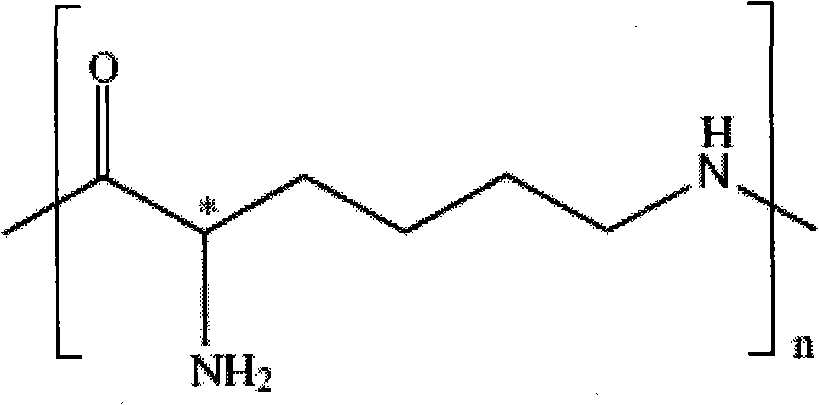

A polylysine microcapsule, alginate gel technology, applied in microcapsule preparation, microsphere preparation, microcapsule and other directions, can solve the limitation of sodium alginate/α-polylysine microcapsule application, biological Poor compatibility, high price and other problems, to achieve the effect of superior membrane strength, low cost, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

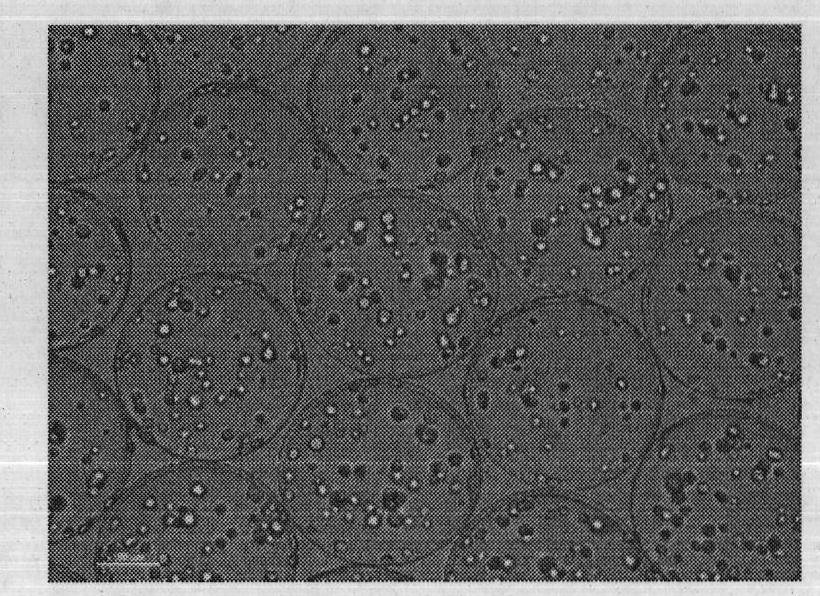

[0038] 1) Using high-voltage electrostatic method [Qu Beibei, Yu Weiting, Liu Xiudong, etc., preparation of monodisperse calcium alginate microgel beads by high-voltage electrostatic method, Acta Chemical Industry, 2005, 56(8): 1547] to prepare embedding Calcium alginate gel microspheres with CHO cells, the initial cell seeding density was 1×10 6 / mL sodium alginate solution.

[0039] 2) Immerse the calcium alginate gel microspheres prepared above into 0.01% (w / v), pH5.5, ε-polylysine / normal saline solution, CHO / calcium alginate gel microspheres and ε - The volume ratio of PLL solution was 1:40, reacted for 60 minutes to prepare ε-AP microcapsules, and then washed 3 times with physiological saline.

[0040] 3) Immerse the ε-AP microcapsules prepared above in a sodium alginate / 0.9% (w / v) NaCl solution with a concentration of 0.05% (w / v), CHO / ε-AP microcapsules and sodium alginate solution The volume ratio was 1:40, and the reaction was carried out for 10 minutes to obtain ε-A...

Embodiment 2

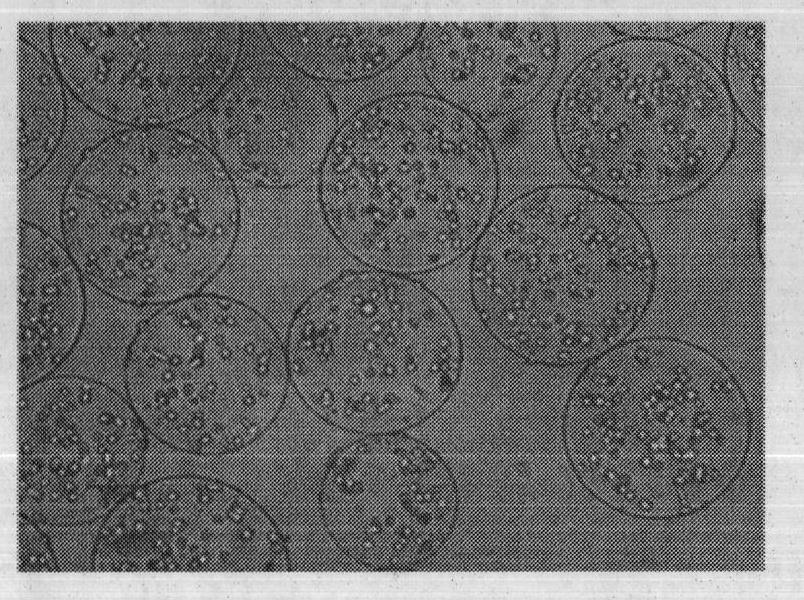

[0045] 1) Calcium alginate gel microspheres embedded with hepatocytes were prepared, and the initial cell seeding density was 1×10 6 / mL sodium alginate solution.

[0046] 2) Immerse the above-mentioned calcium alginate gel microspheres into 0.1% (w / v), pH6.5, ε-polylysine / normal saline solution, and hepatocytes / calcium alginate gel microspheres and The volume ratio of ε-PLL solution was 1:20, and reacted for 15 minutes to prepare ε-AP microcapsules, which were then washed 3 times with normal saline.

[0047] 3) The ε-AP microcapsules prepared above were immersed in the sodium alginate / 0.9% (w / v) NaCl solution with a concentration of 0.1% (w / v), and the liver cells / ε-AP microcapsules and sodium alginate The volume ratio of the solution was 1:20, and the reaction was carried out for 15 minutes to obtain ε-APA microcapsules, which were washed with physiological saline for 3 times.

[0048] 4) Immerse the above-prepared ε-APA microcapsules in 55 mmol / L sodium citrate solution, ...

Embodiment 3

[0052] 1) Prepare calcium alginate gel microspheres embedded with embryonic stem cells (ES), and the initial cell seeding density is 1×10 7 / mL sodium alginate solution.

[0053] 2) Immerse the calcium alginate gel microspheres prepared above into 0.2% (w / v), pH7.4, ε-polylysine / normal saline solution, ES / calcium alginate gel microspheres and ε - The volume ratio of the PLL solution was 1:5, reacted for 15 minutes to prepare ε-AP microcapsules, and then washed 3 times with physiological saline.

[0054] 3) Immerse the ε-AP microcapsules prepared above in a sodium alginate / 0.9% (w / v) NaCl solution with a concentration of 0.2% (w / v), ES / ε-AP microcapsules and sodium alginate solution The volume ratio was 1:5, and the reaction was carried out for 10 minutes to obtain ε-APA microcapsules, which were washed with normal saline for 3 times.

[0055] 4) Immerse the above-prepared ε-APA microcapsules in 55 mmol / L sodium citrate solution, the volume ratio of ES / ε-APA microcapsules to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com