Ion exchange nonwoven fabric with high carboxyl content and preparation method thereof

An ion exchange and non-woven technology, applied in the field of high carboxyl content ion-exchange non-woven fabric and its preparation, can solve the problem of limiting the exchange capacity of ion-exchange non-woven fabric, expensive and rare operations of instruments and devices, low graft reaction efficiency, etc. problems, to achieve the effects of easy industrialization and implementation, fast exchange rate, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Cut a batch of circular PP non-woven fabrics with a diameter of 8cm (commercially available, specification: 8.5g / m 2 , thickness 64.5μm), soak in acetone for 12h to remove impurities such as surface oil and additives, take it out and dry it for later use.

[0041] Acetone is made into a mixed solvent with 50% (volume percentage) and distilled water, and acrylic acid, benzophenone and azobisisobutyronitrile are added to make a monomer solution for subsequent use, and the concentration of each component is 50% (volume percentage) of acrylic acid, Benzophenone 25.0g / L and azobisisobutyronitrile 0.5g / L.

[0042] Soak the clean and dry PP non-woven fabric in the above monomer solution for 1.5h, take out the PP non-woven fabric, spread it on a glass watch glass in a 2-layer stack, seal it with PE film (thickness 23μm) and pass through N 2 After exhausting the air, keep the sealed state and irradiate with a 500W ultraviolet lamp for 1.5h (irradiation distance is 15cm). Then ...

Embodiment 2

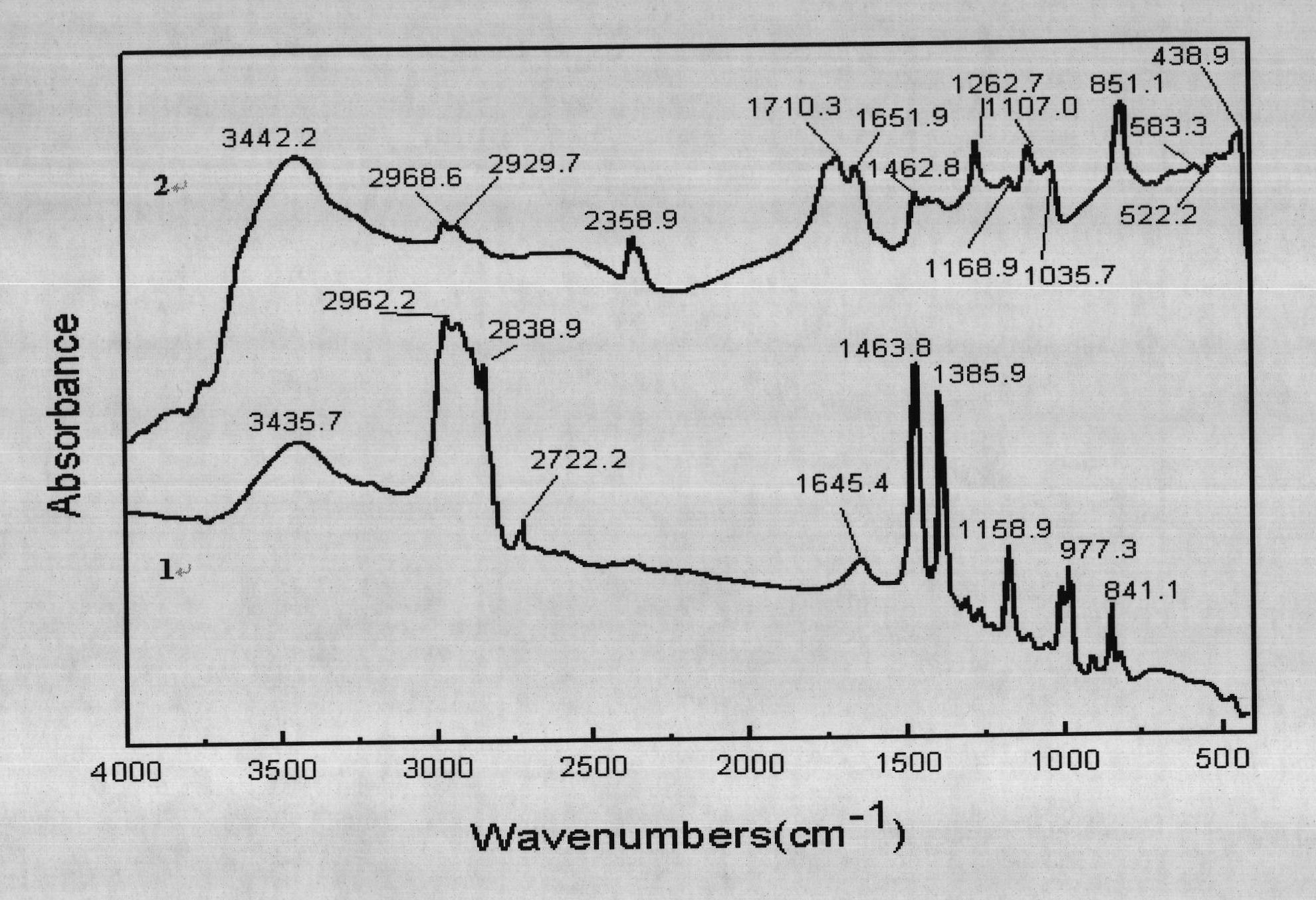

[0044] Repeat Example 1, only change the number of stacked layers of PP non-woven fabric to 3 layers, the average carboxyl content of the gained ion-exchange non-woven fabric is 12.86mmol / g, and its FTIR spectrogram is shown in figure 1 Spectrum line 2, its optical picture after water absorption and saturation is shown in Figure 2, and the scanning electron microscope (SEM) picture is shown in Figure 3.

[0045] figure 1 On the infrared absorption curves of PP non-woven fabrics and PP ion-exchange non-woven fabrics shown, 2960cm -1 The absorption at the position is attributed to the -CH in the PP molecule 2 stretching vibration, 1160-1650cm -1 The absorption attributed to =CH 2 -CH 3 bending deformation vibration. 1710.3cm -1 The absorption peak of is attributed to the carbonyl stretching vibration of acrylic acid, which confirms that acrylic acid has been successfully grafted on PP molecules in this example.

[0046] The saturated water absorption (24h / 25°C) of the PP ...

Embodiment 3

[0050] Example 1 was repeated, only the number of stacked layers of the PP non-woven fabric was changed to 4 layers during UV irradiation, and the average carboxyl content of the obtained ion-exchange non-woven fabric was 12.93 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com