Silicon-based Al2O3 film chip capacitor and making method thereof

A thin-film chip and capacitor technology, applied in thin-film/thick-film capacitors, stacked capacitors, fixed capacitor electrodes, etc., can solve the problems of changing chip capacitance height, fixed silicon wafer thickness, poor withstand voltage characteristics, etc., to improve bonding Strength, low cost, good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

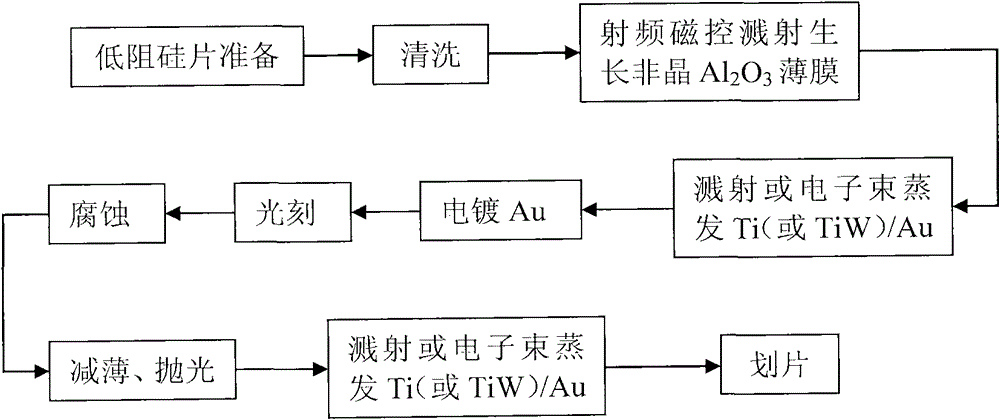

[0026] Below in conjunction with accompanying drawing, describe silicon-based Al of the present invention in detail with embodiment 2 o 3 Structure and characteristics of film chip capacitors. Si-based Al 2 o 3 The thin film chip capacitor and its manufacturing process all belong to the protection scope of the present invention.

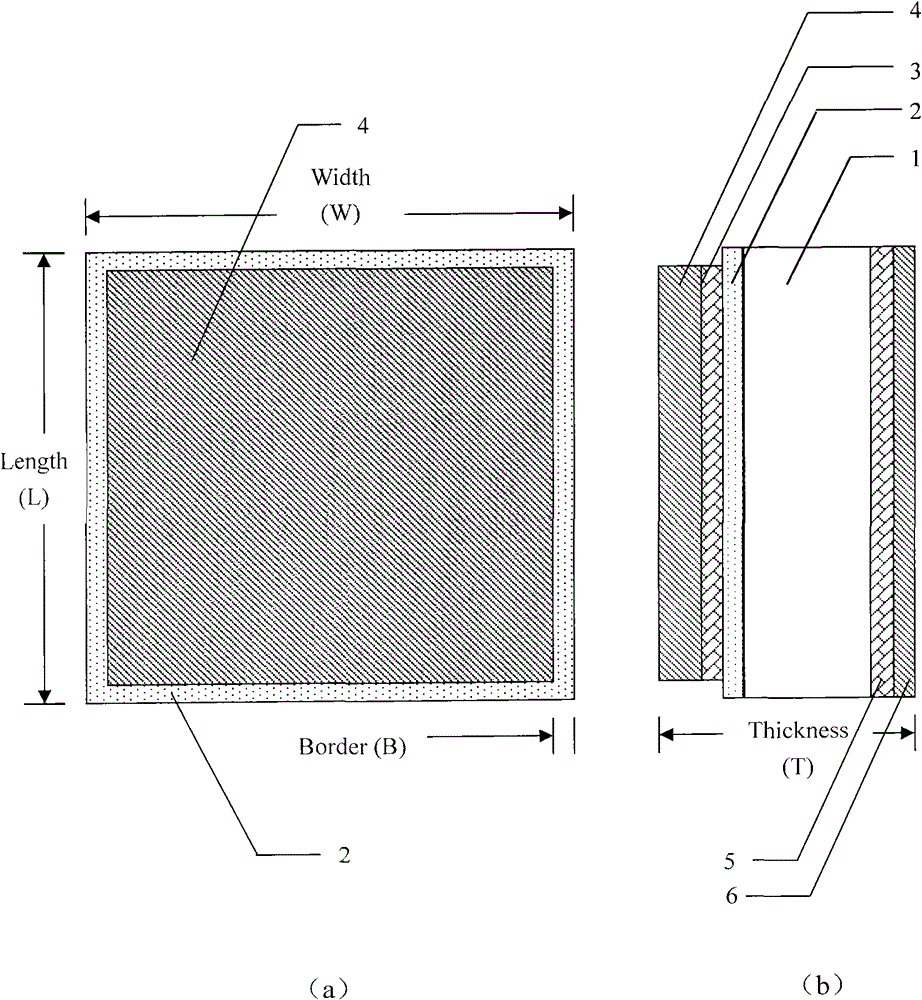

[0027] figure 1 Silicon-based Al showing the present invention 2 o 3 Schematic diagram of the structure of a thin film chip capacitor. Such asfigure 1 (a) As shown in the top view, the edges of the upper electrode Au layer 4 and Ti (or TiW) layer 3 are in contact with Al 2 o 3 A Border (B) region with a width of at least 25 μm is reserved at the edge of the insulating dielectric layer 2 . The edge area B not only improves the breakdown resistance of the edge of the upper electrode plate, but also prevents damage to the insulating medium of the chip capacitor by the scribing process. figure 1 (b) The cross-sectional view more clearly shows t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com