Test strip for detecting heavy metal-chromium (Cr) in water quality and preparation method thereof

A technology of test strips and heavy metals, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of being unsuitable for on-site detection of chromium and complicated processing procedures, and achieve Effects of shortened sample processing time, high recovery rate, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

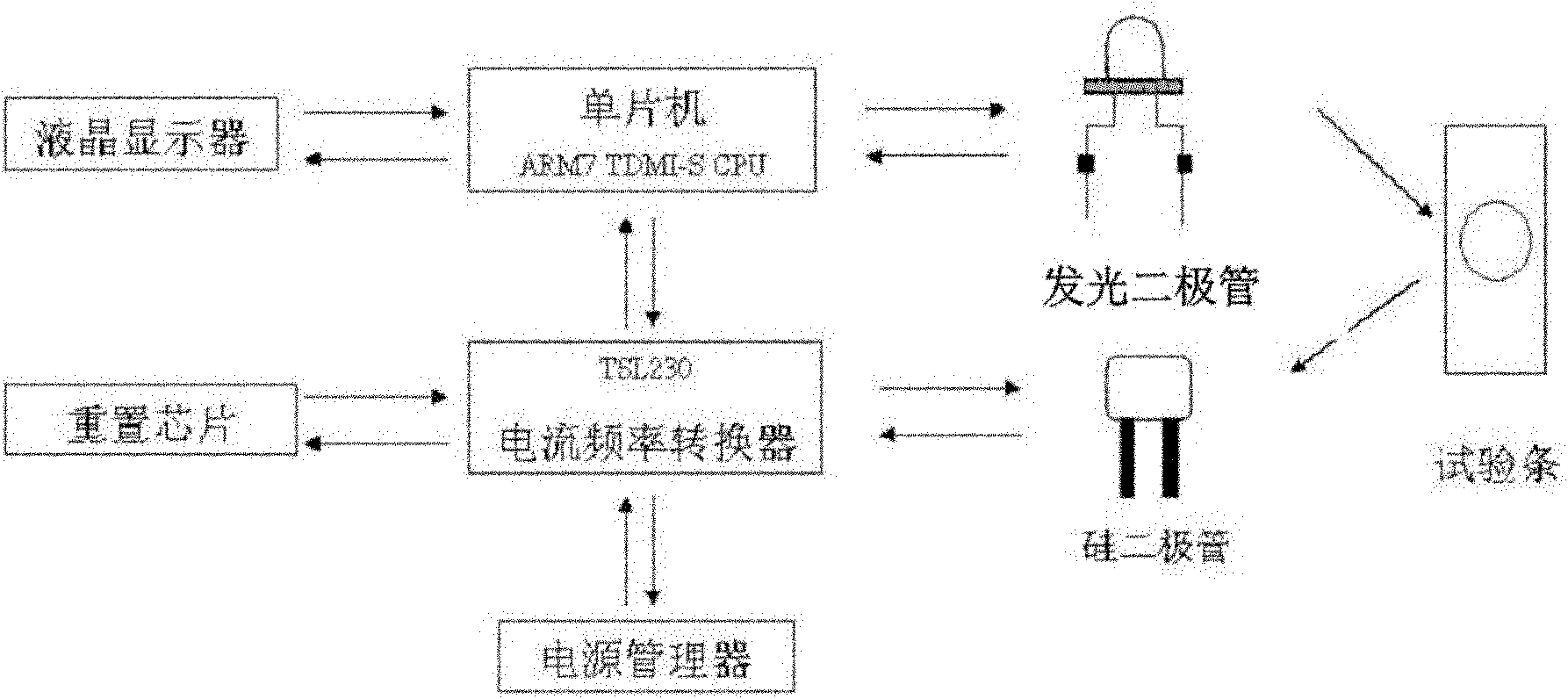

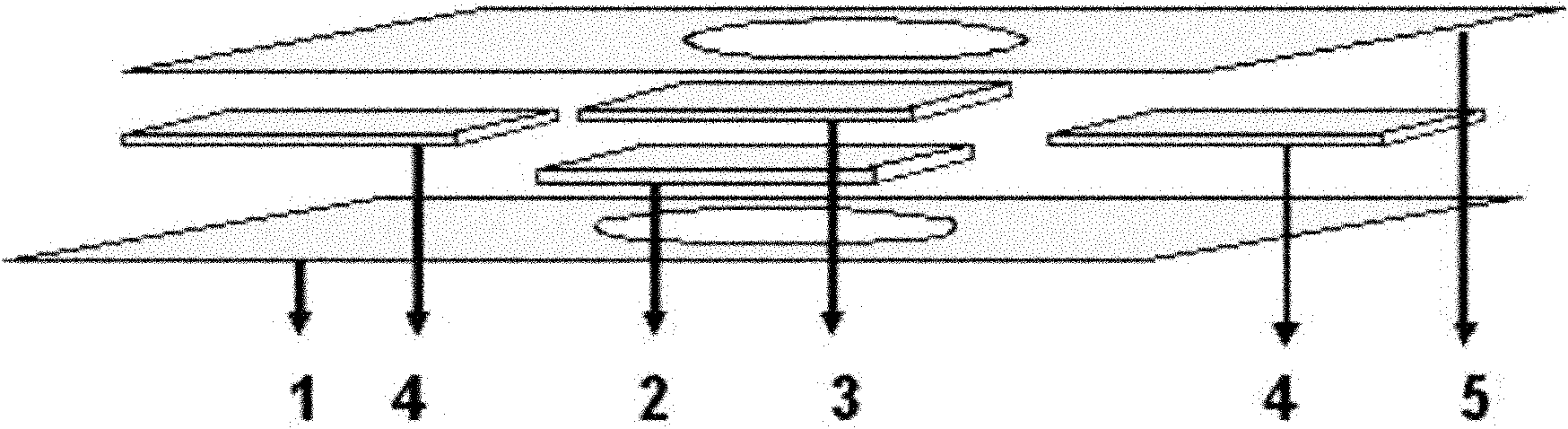

[0026] figure 1 It is a schematic diagram of the use and detection principle of the rapid detection chromium test strip of the present invention. The light is reflected from the light-emitting diode to the test area of the test strip, and the reflected light is received by the silicon diode and converted into an electrical signal for transmission, and finally displayed on the display. And the intensity of the electric signal is directly proportional to the color depth of the test area of the test strip. The test strip in the present embodiment comprises insulating waterproof substrate 1, reaction substrate film 2, filter layer 3, spacer 4 and cover sheet 5, as figure 2 shown. After the insulating and waterproof substrate 1 and the cover sheet 5 are superimposed, the hole is punched by mechanical punching method. The hole diameter is 0.3mm, and the hole wall is 2mm away from the edge of the substrate. The adsorption effect makes the sample evenly distributed in the sampl...

Embodiment 2

[0035] (1) Obtaining of samples to be tested: same as in Example 1.

[0036] (2) Production of the reaction substrate film: including the reaction substrate film layer and the substrate film carrier. The substrate film carrier requires excellent light transmission and reflection functions. It is recommended to use polyvinyl chloride sheet, the optimum thickness is 80nm. The film layer of the reaction substrate is the coating of the developer. The basic production method is to weigh 0.148g of cetyltrimethylamine bromide, 2mL of 2% polyvinyl alcohol, and 2.08g of citric acid dissolved in 10mL of distilled water, that is, solution A and then accurately weigh the color developer diphenylcarbonyl Dihydrazine 0.968g, dissolved in 20mL acetone, solution B. Finally, mix the two solutions of A and B and pour them into a mortar, then add 3 g of water-soluble chitosan and 5 g of silica gel to fully grind to obtain a viscous film-forming agent. Finally, the prepared film-forming agent ...

Embodiment 3

[0042] (1) Obtaining of samples to be tested: same as in Example 1.

[0043] (2) Production of the reaction substrate film: including the reaction substrate film layer and the substrate film carrier. The substrate film carrier requires excellent light transmission and reflection functions. It is recommended to use polyvinyl chloride sheet, the optimum thickness is 80nm. The film layer of the reaction substrate is the coating of the developer. The basic production method is to weigh 0.296g of cetyltrimethylamine bromide, 3mL of 2% polyvinyl alcohol, and 2.08g of citric acid dissolved in 10mL of distilled water, that is, solution A and then accurately weigh the color developer diphenylcarbonyl Dihydrazine 1.936g, dissolved in 20mL acetone, that is solution B. Finally, mix the two solutions of A and B and pour them into a mortar, then add 4g of water-soluble chitosan and 6g of silica gel to fully grind to obtain a viscous film-forming agent. Finally, the prepared film-forming ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com