Method for preparing modified titanium dioxide nanotube dye-sensitized photoanode thin film

A technology of titanium dioxide and dye sensitization, which is applied in the field of dye-sensitized solar cells, can solve the problems of difficult solar cell performance and high energy consumption, and achieve the effects of improving electron transmission rate, increasing open circuit voltage, and improving sunlight utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

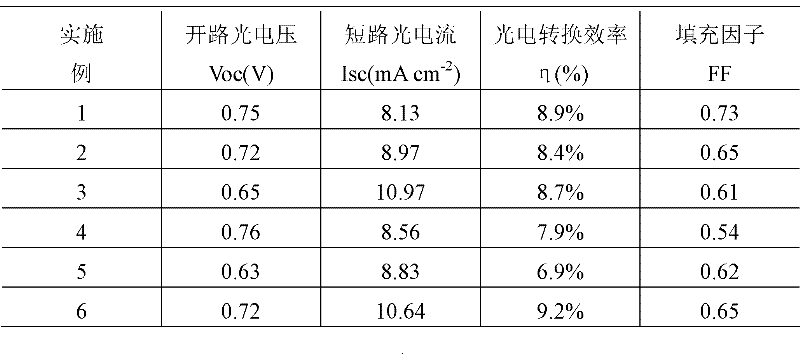

Examples

example 1

[0026] (1) Weigh 0.7612g of thiourea into a 50ml beaker, dissolve it in 10ml of ethanol aqueous solution with a volume ratio of 1:1, add 5ml of 4M titanium tetrachloride hydrochloric acid solution dropwise to the thiourea solution, and stir for 1 hour , Aging for 24 hours to obtain titanium dioxide sol A doped with S and N elements;

[0027] (2) Preparation of titanium dioxide nanotubes by hydrothermal synthesis. Weigh 6 g of commercially available titanium dioxide P-25, add it to a 15M sodium hydroxide solution and stir for 24 hours. The suspension was put into a stainless steel reaction kettle lined with polytetrafluoroethylene and placed in an oven at 60°C for 96 hours of reaction. After centrifugal separation, a white solid product was obtained, which was washed with deionized water to neutrality (PH=7). The water-washed product was added to 0.1M hydrochloric acid and stirred for 10 hours, and finally washed with deionized water to neutral (PH=7), washed with absolute ethan...

example 2

[0033] (1) Weigh 0.7612g of tetrabutylammonium into a 50ml beaker, dissolve it in 10ml of ethanol aqueous solution with a volume ratio of 1:1, add 5ml of 4M titanium propoxylate solution dropwise to the tetrabutylammonium solution, Stir for 1 hour and aging for 24 hours to obtain titanium dioxide sol A doped with C and N elements;

[0034] (2) Prepare titanium dioxide nanotubes by hydrothermal synthesis. Weigh 6 g of commercially available titanium dioxide P-25, add it to a 7M sodium hydroxide solution and stir for 24 hours. The suspension was put into a stainless steel reaction kettle lined with polytetrafluoroethylene and placed in an oven at 90°C to react for 92 hours. After centrifugal separation, a white solid product was obtained, which was washed with deionized water to neutrality (PH=7). The water-washed product was added to 0.1M hydrochloric acid and stirred for 9 hours, and finally washed with deionized water to neutrality (PH=7), washed 3 times with absolute ethanol,...

example 3

[0040] (1) Take 10ml of tetrabutyl titanate solution in a beaker, add 10ml of absolute ethanol to it, and finally 2ml of 0.5M tin chloride solution, the molar ratio of titanium salt to tin salt is 20:1, stir for 2h, aging After 24 hours, Sn-doped titanium dioxide sol A was obtained.

[0041] (2) Prepare titanium dioxide nanotubes by hydrothermal synthesis. Weigh 6 g of commercially available titanium dioxide P-25, add it to a 15M sodium hydroxide solution and stir for 24 hours. The suspension was put into a stainless steel reaction kettle lined with polytetrafluoroethylene and placed in an oven at 120°C for 90 hours of reaction. After centrifugal separation, a white solid product was obtained, which was washed with deionized water to neutrality (PH=7). The water-washed product was added to 0.1M hydrochloric acid and stirred for 6 hours, and finally washed with deionized water to neutrality (PH=7), washed with absolute ethanol 3 times, centrifuged, and dried at 70°C to obtain ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com