Rare-earth composite antibacterial agent and application thereof

A technology of rare earth compounding and antibacterial agent, which is applied in the direction of application, biocide, disinfectant, etc., can solve the problems of affecting the appearance of white or light-colored products, easy to turn black, and rare antibacterial agents, etc., to achieve inhibition of bacterial growth and good structure Stability, good resistance to discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] At room temperature, dissolve 9g of lanthanum nitrate and 5g of silver nitrate into 150g of deionized water to disperse. After 4 hours of electric stirring to disperse completely, then add 15g of nano-montmorillonite and stir evenly. Add 0.02ml of NaOH, a black precipitate is formed immediately, stop adding NaOH , stirred for 12 hours until the reaction was complete, washed repeatedly with deionized water until neutral, separated, dried, pulverized, and passed through a 200-mesh sieve to obtain sample 1.

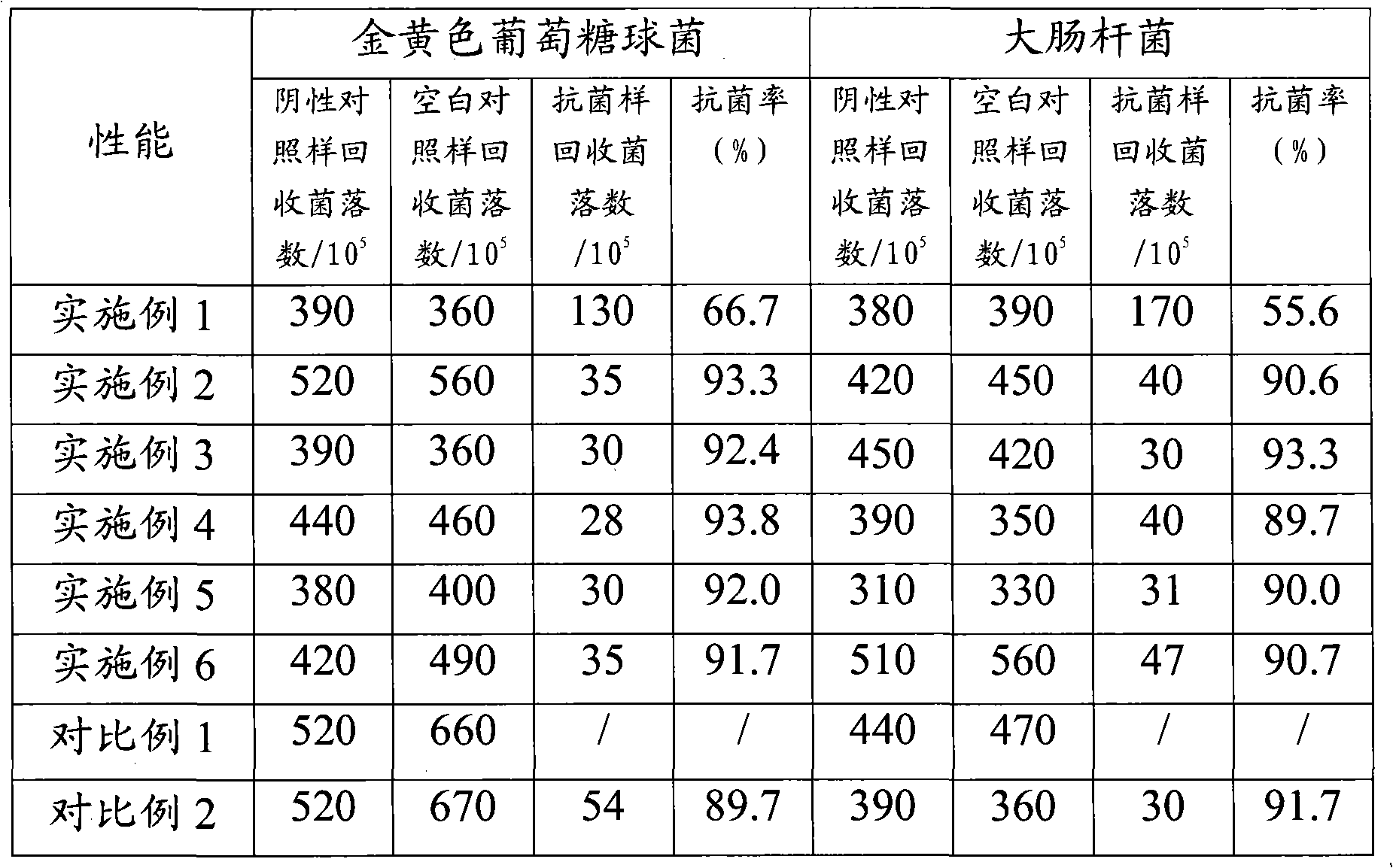

[0035] Get 100g of polypropylene, 0.2g of white mineral oil, and 2g of sample 1, mix them uniformly in a twin-screw, and then cut into pellets. The temperature of each section of the extruder is 160-220° C., and the screw speed is 100-300 rpm. After granulation and drying, the national standard antibacterial performance test sample was prepared on a flat vulcanizer. In the antibacterial performance test, Staphylococcus aureus (ATCC 6538) and Escherichia coli (ATCC 259...

Embodiment 2

[0037] At 60-80°C, add 30g of nano-montmorillonite to 250g of water and stir to disperse evenly. Adjust the pH to 7. After 4 hours of electric stirring for complete dispersion, add 4g of silver nitrate and 6g of cerium nitrate and stir to dissolve. Add NaOH , after adjusting the pH value to 5, keep stirring in the dark for 12 hours until the reaction is complete, wash repeatedly with deionized water until neutral, separate, dry, pulverize, and pass through a 200-mesh sieve to obtain sample 2.

[0038] Get 100g of polypropylene, 0.2g of white mineral oil, and 2g of sample 2 in a twin-screw and mix them uniformly before cutting into pellets. The temperature of each section of the extruder is 160-220° C., and the screw speed is 100-300 rpm. After granulation and drying, the national standard antibacterial performance test sample was prepared on a flat vulcanizer. In the antibacterial performance test, Staphylococcus aureus (ATCC 6538) and Escherichia coli (ATCC 25922) were select...

Embodiment 3

[0040] At 60-80°C, add 15g of zeolite and 15g of nano-montmorillonite to 250g of water and stir to disperse evenly, adjust the pH value to 7, and stir for 4 hours after the dispersion is complete, then add 4g of copper chloride and 6g of cerium nitrate and stir to dissolve. Mix well, add NaOH, adjust the pH value to 5, keep stirring in the dark for 12 hours until the reaction is complete, wash with deionized water repeatedly until neutral, separate, dry, pulverize, and then pass through a 200-mesh sieve to obtain sample 3.

[0041] Take 100g of polypropylene, 0.2g of white mineral oil, and 2g of sample 3, mix them uniformly in a twin-screw, and then cut into pellets. The temperature of each section of the extruder is 160-220° C., and the screw speed is 100-300 rpm. After granulation and drying, the national standard antibacterial performance test sample was prepared on a flat vulcanizer. In the antibacterial performance test, Staphylococcus aureus (ATCC 6538) and Escherichia c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com