Process method for producing copper sulfate by using copper scale at normal temperature and normal pressure

A process method, copper sulfate technology, applied in the field of comprehensive recycling of non-ferrous metal smelting slag, can solve the problems of large environmental pollution, high production energy consumption, long process, etc., achieve low investment in industrialization, reduce energy consumption in the heating process, and process The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

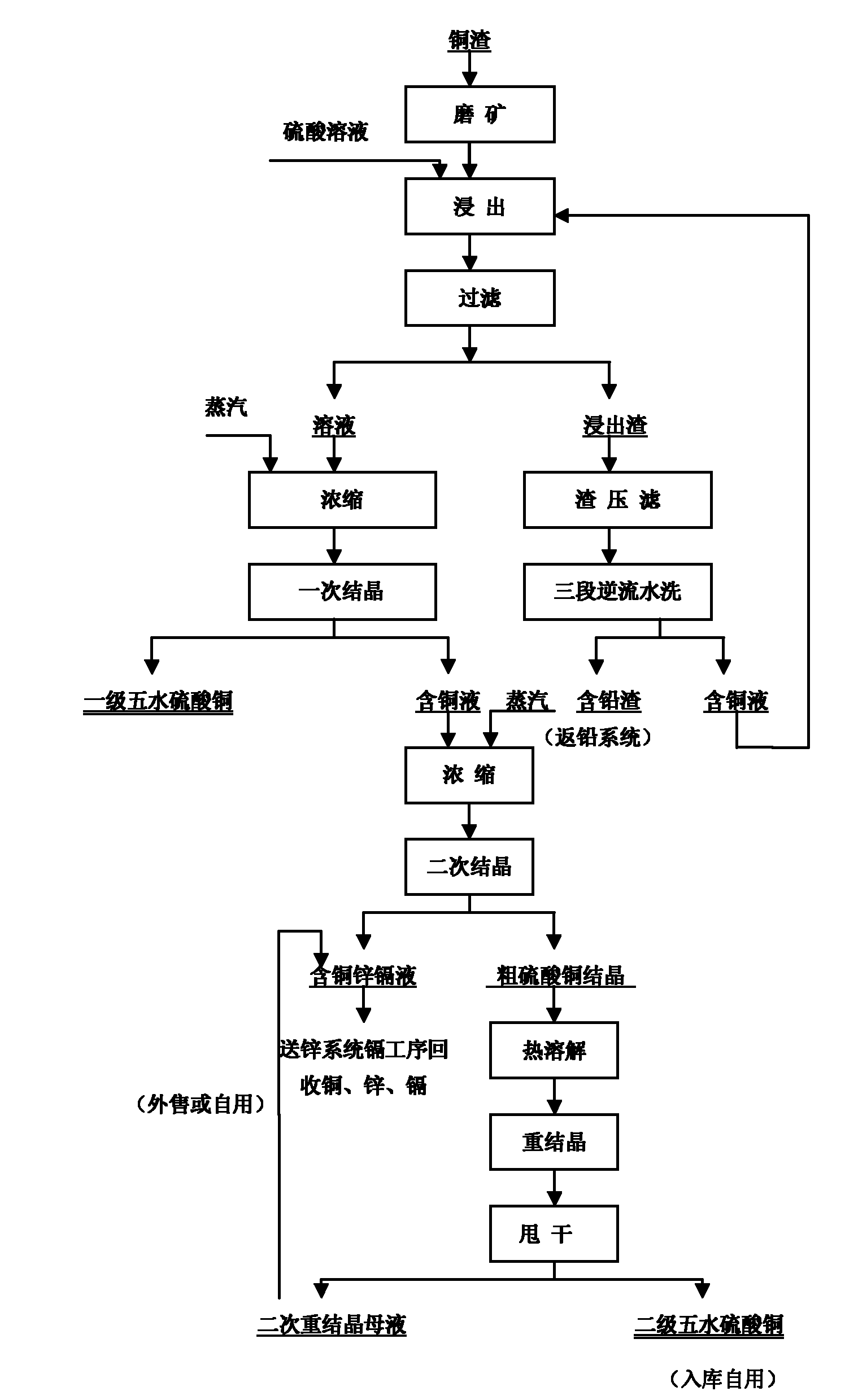

Method used

Image

Examples

Embodiment 1

[0038] Add 25.43% copper, 10.69% zinc, 6.73% Cd, dry weight 3kg, moisture 41.69%, particle size -120 mesh copper slag into a 20L leaching tank with mechanical stirring, and blow into the tank ~0.05m 3 .min -1 .Kg Copper slag -1 Air (0.06MPa), the initial acid concentration is 165g.L -1 , Liquid-solid ratio is 5:1, rotating speed 400r.min -1 , Leaching time 24h, can get Cu41g.L -1 The leaching solution is 17.4L, and the leaching residue is 1.35kg. The leaching residue contains Cu3.05%, Zn 4.53%, and contains high lead and silver. It can be recovered by the lead system. The leaching rate of copper reaches 94.33%. Add 20g.L to the extract at 60℃ -1 Polyacrylamide, clarification time 3h, clarification filtration, concentration removal of calcium and magnesium, concentration time 7-9h, after concentration the liquid control specific gravity 1.42 to start crystallization, crystallization filtration temperature 30℃, one-time crystallization copper sulfate pentahydrate 1.92kg, copper su...

Embodiment 2

[0040] Add 42.73% copper, 4.98% zinc, 3.45% Cd, 2.4kg dry weight, 42.58% moisture, and copper slag with a particle size of -150 mesh into a 20L leaching tank with mechanical stirring, and drum into the tank. Entry ~ 0.2m 3 .min -1 .Kg Copper slag -1 Air (0.07MPa), the initial acid concentration is 155g.L -1 , Liquid-solid ratio is 5.5:1, rotating speed is 380r.min -1 , Leaching time 24h, Cu can be obtained 2+ 58.03g.L -1 The leaching solution is 16.4L, and the leaching residue is 1.1kg. The leaching residue contains 5.12% Cu and 2.67% Zn. The treatment method for this residue is the same as above. The leaching rate of copper is 94.54%. Add 20g.L to the extract at 60℃ -1 Polyacrylamide, clarification time 3h, clarification filtration, concentration removal of calcium and magnesium, concentration time 6-8h, after concentration the liquid control specific gravity 1.45 to start crystallization, crystallization filtration temperature 30℃, one-time crystallization of copper sulfate pe...

Embodiment 3

[0042] Add 58.85% copper, 3.14% zinc, 1.21% Cd, dry weight 2.6kg, moisture 47.69%, particle size -180 mesh copper slag into a 20L leaching tank with mechanical stirring, and drum into the tank Into ~ 0.3m 3 .min -1 .Kg Copper slag -1 Air (0.07MPa), initial acid concentration 175g.L -1 , The liquid-solid ratio is 6:1, the speed is 350r / min, and the leaching time is 24h, and Cu can be obtained 2+ 75.24g.L -1 The leaching solution is 18.6L and the leaching residue is 1.26kg. The leaching residue contains 2.94% Cu and 0.64% Zn, and the copper leaching rate is 97.58%. Add 10g.L to the extract at 60℃ -1 Polyacrylamide, clarification time 2h, clarification filtration, concentration removal of calcium and magnesium, concentration time 5-7h, after concentration the liquid control specific gravity 1.45 starts to crystallize, crystallization filtration temperature 30℃, one-time crystallization copper sulfate pentahydrate 3.77kg, copper sulfate pentahydrate The main content is 97.35%, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com