Preparation method of graphene-loaded nanometre cobalt hydroxide (Co(OH)2) composite material

A technology of composite materials and graphene, which is applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve problems such as easy agglomeration and affecting the excellent performance of nano-effects, and achieve convenient post-processing, excellent electrochemical performance, and solution The effect of the reunion problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

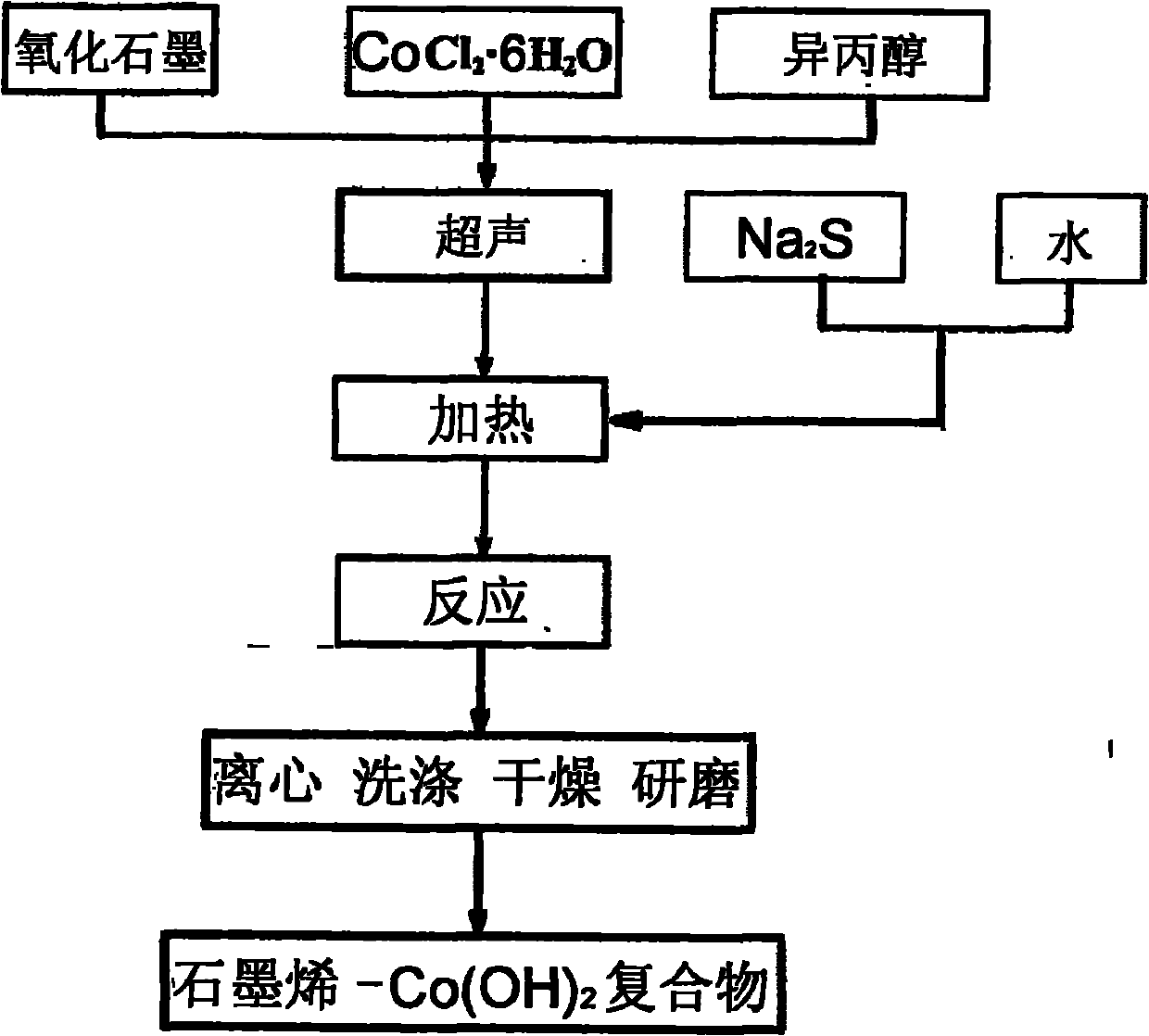

[0016] combine figure 1 , graphene-loaded nanometer Co(OH) of the present invention preparation method, comprises the following steps:

[0017] Step 1: Mix CoCl2·6H2O, graphite oxide and isopropanol to make a solution, and disperse evenly by ultrasonic;

[0018] Step 2: heat up the solution prepared in step 1 under stirring;

[0019] Step 3: Na2S and water are added to the mixed solution of step 2 to react, and the reaction equation is:

[0020]

[0021] CoCl2+2NaOH→Co(OH)2+2NaCl;

[0022] Step 4: Centrifuge, wash, dry, and grind the black precipitate obtained from the reaction in Step 3 to obtain a graphene-supported nano-Co(OH)2 composite material.

[0023] The concentration of graphite oxide in isopropanol is 0.0001-0.001g / mL. The concentration of CoCl2·6H2O in isopropanol is 0.01272~0.1272g / mL. In step 2, the temperature is raised to 60° C. to 83° C. The reaction time in step 3 is 10 min to 10 h. The mass ratio of CoCl2.4H2O to Na2S is 1:0.1-1. The concentration...

Embodiment 1

[0026] Step 1: Mix 1.908g CoCl2·6H2O, 0.025g graphite oxide and 50mL isopropanol to form a solution, and disperse evenly by ultrasonic;

[0027] Step 2: Heat up the solution prepared in Step 1 to 60°C under stirring;

[0028] Step 3: Dissolve 0.34g Na2S in 10mL of water and add it to the mixture in step 2, react for 10min, the reaction equation is:

[0029]

[0030] CoCl2+2NaOH→Co(OH)2+2NaCl;

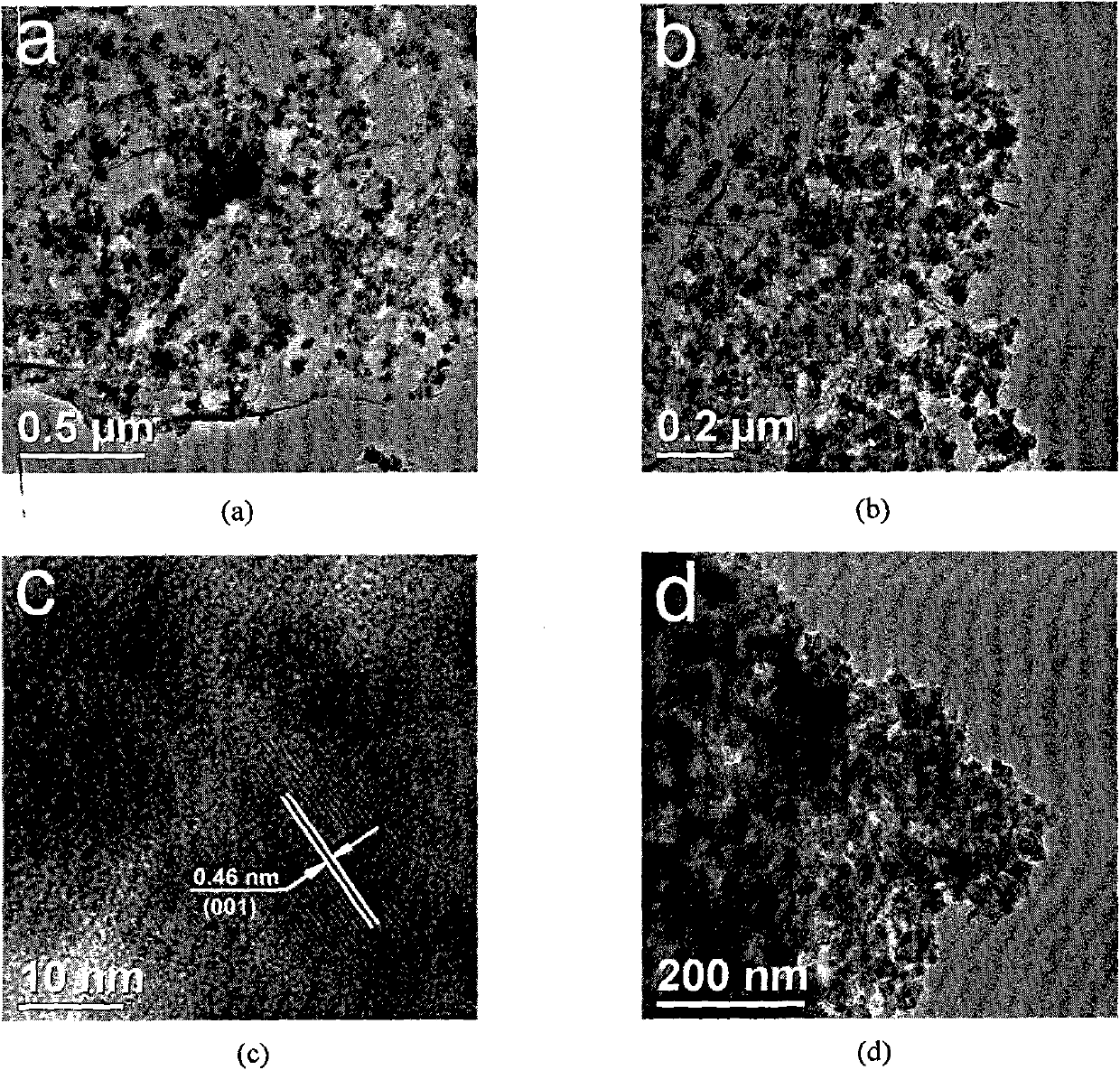

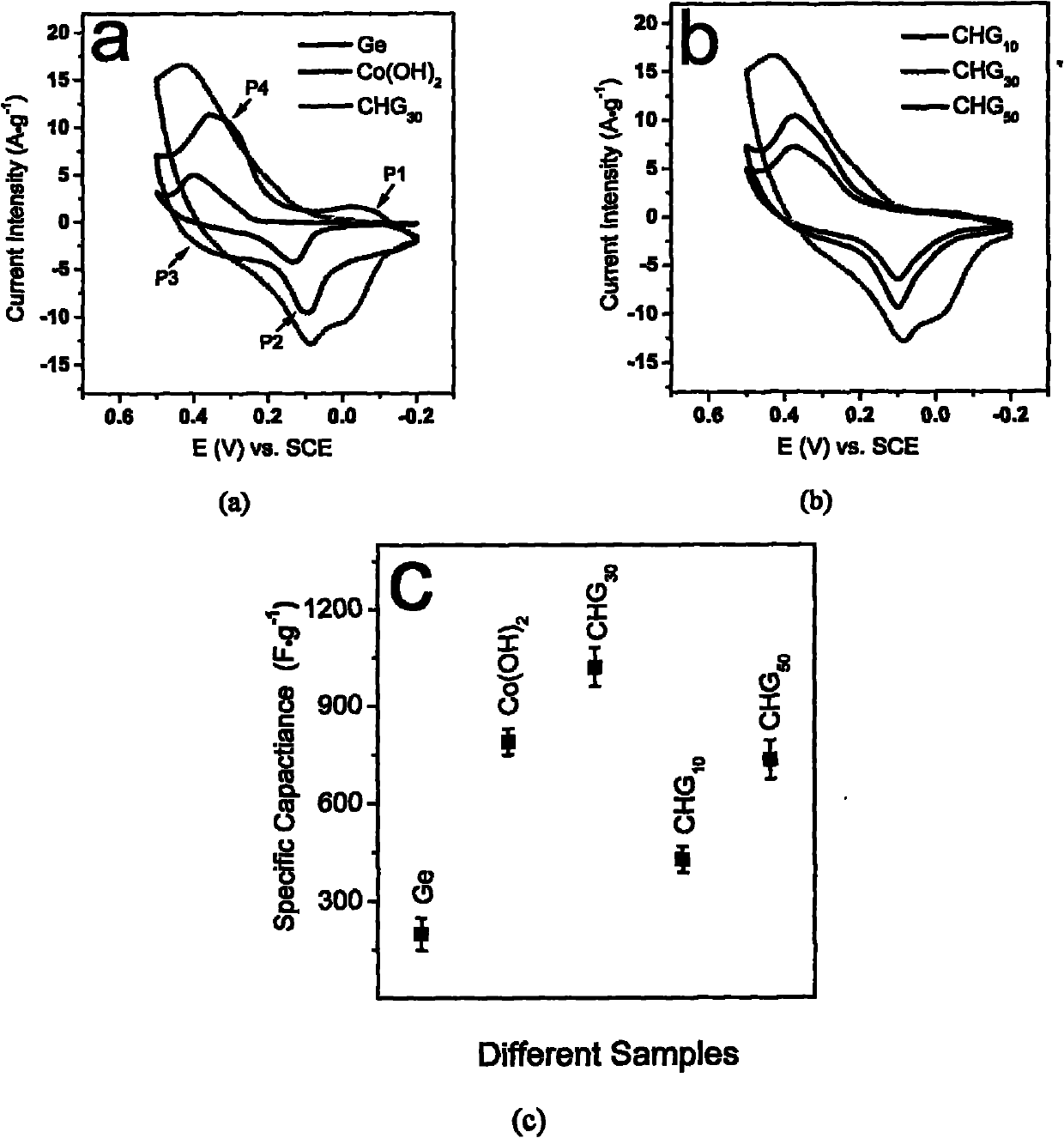

[0031] Step 4: Centrifuge, wash, dry, and grind the black precipitate obtained in Step 3 to obtain a graphene-supported nano-Co(OH)2 composite material, and the feed ratio is Co(OH)2 / GO=30 / 1. The transmission electron microscope test results are as follows: figure 2 c, d shown. The results of cyclic voltammetry were as image 3 shown.

[0032] according to image 3 Calculated, the capacitance of the composite material is 1020.1F / g. The capacitance of Co(OH)2 alone is 789.4F / g, and that of GO alone is 198.9F / g. It can be seen that when the two are combined, the capacitance of...

Embodiment 2

[0034] Step 1: Mix 0.636g CoCl2·6H2O, 0.025g graphite oxide and 50mL isopropanol to form a solution, and disperse evenly by ultrasonic;

[0035] Step 2: Heat up the solution prepared in Step 1 to 60°C under stirring;

[0036] Step 3: Dissolve 0.34g Na2S in 10mL of water and add it to the mixture in step 2, react for 10min, the reaction equation is:

[0037]

[0038] CoCl2+2NaOH→Co(OH)2+2NaCl;

[0039] Step 4: Centrifuge, wash, dry, and grind the black precipitate obtained in Step 3 to obtain a graphene-supported nano-Co(OH)2 composite material, and the feed ratio is Co(OH)2 / GO=10 / 1. The transmission electron microscope test results are as follows: figure 2 a, b shown. The results of cyclic voltammetry were as image 3 shown. It was determined that the specific capacitance of the obtained composite material was 427.8 F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com