Front electrode structure of schottky diode and process manufacturing method of front electrode structure

A technology of Schottky diodes and front electrodes, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as low packaging yield, device damage, physical characteristics, and electrical characteristics, and achieve anti-ESD Ability improvement and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The entire Schottky diode manufacturing process is further described below in conjunction with the accompanying drawings. As described in the background technology, the front electrode structure of the conventional Schottky diode chip is mostly made of Ti (titanium)-Ni (nickel)-Ag (silver ), V (vanadium)-Ni (nickel)-Ag (silver) and a class of three-layer structure, the realization steps are as follows:

[0035] The voltage divider ring and the main junction of the conventional planar high-voltage transistor are formed at the same time, and the implementation steps are as follows:

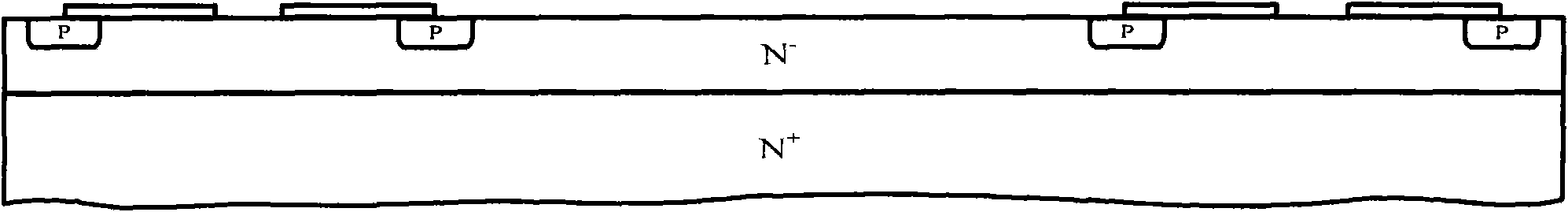

[0036] 1. Clean the Schottky diode chip before vacuum evaporation coating, as shown in Figure 1(a);

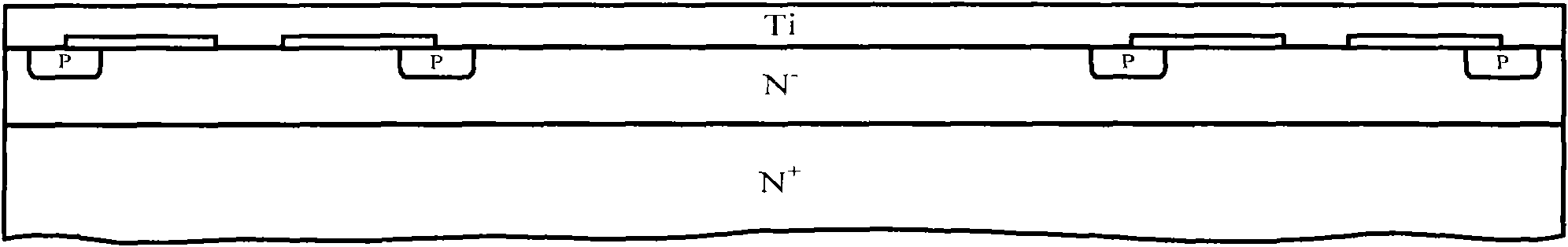

[0037] 2. Vacuum evaporation of metal Ti or V in the contact layer, as shown in Figure 1(b);

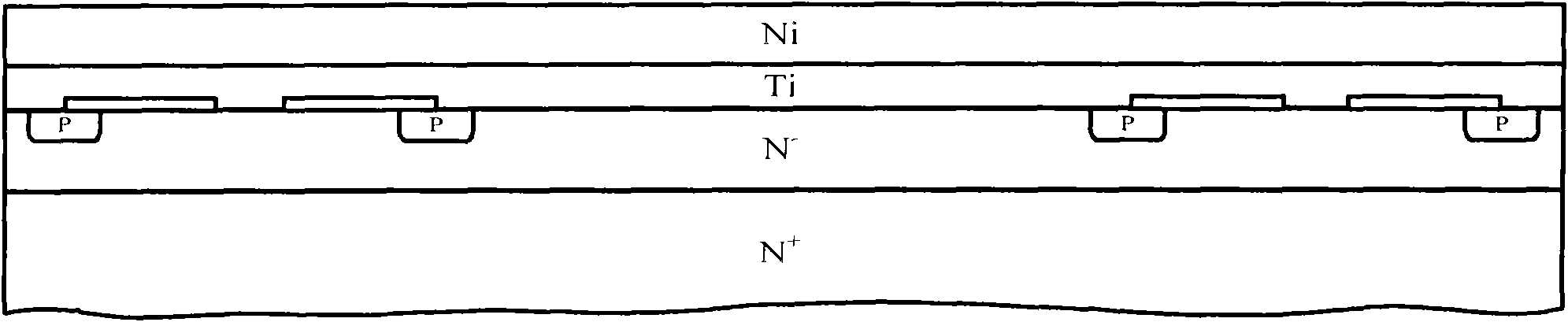

[0038] 3. Vacuum evaporation transition layer metal Ni, as shown in Figure 1(c);

[0039] 4. Vacuum evaporation of conductive layer metal Ag, as shown in Figure 1(d);

[0040] 5. Perform photolit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com