Method for producing methane by means of fermentation with jet mixing technology

A technology of stirring fermentation and reflux stirring, which is applied in fermentation, biosynthesis, biological sludge treatment, etc., can solve the problems of poor contact between solid raw materials and fermentation bacterial mass, difficulty in fermentation to achieve the predetermined effect, and large power consumption of mechanical stirring, etc. Achieve the effect of small footprint, simple structure and low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

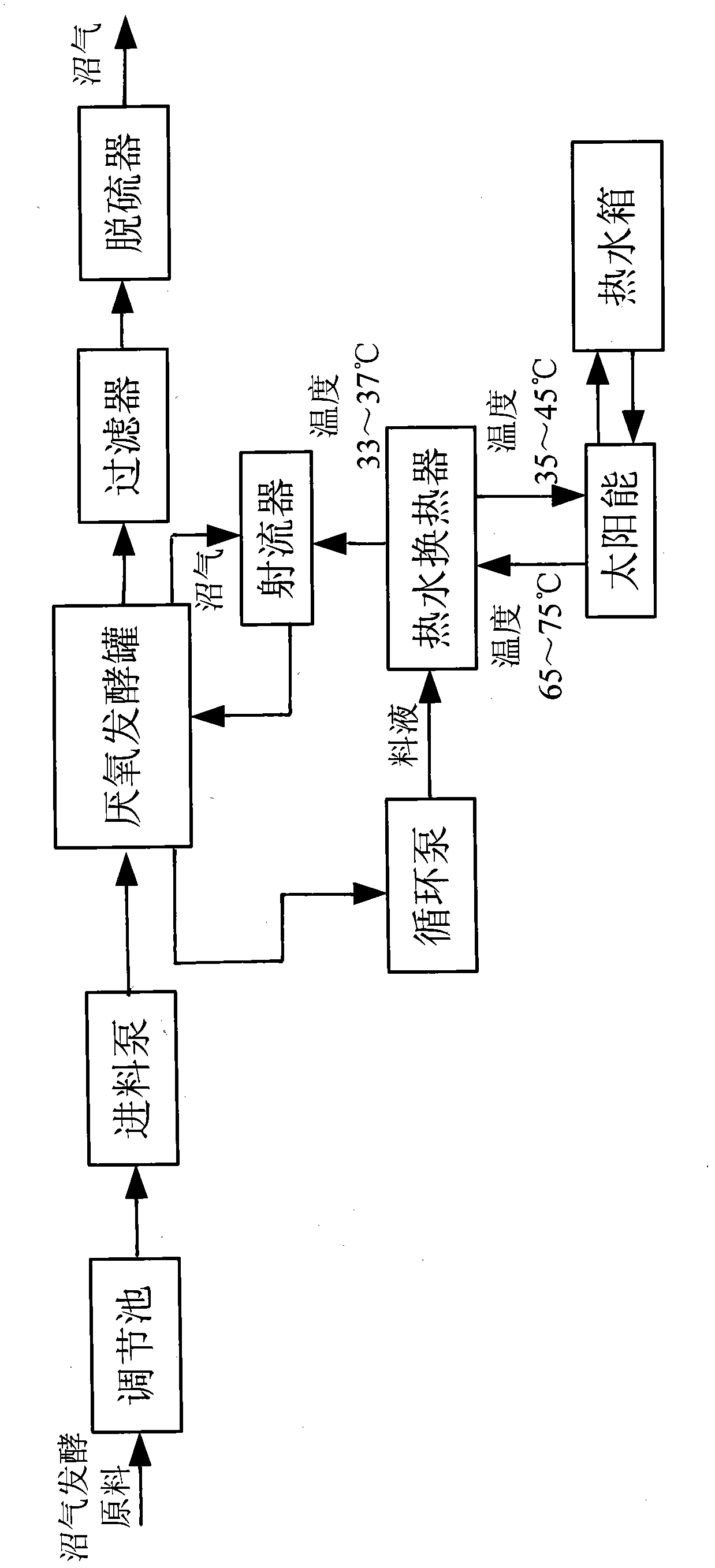

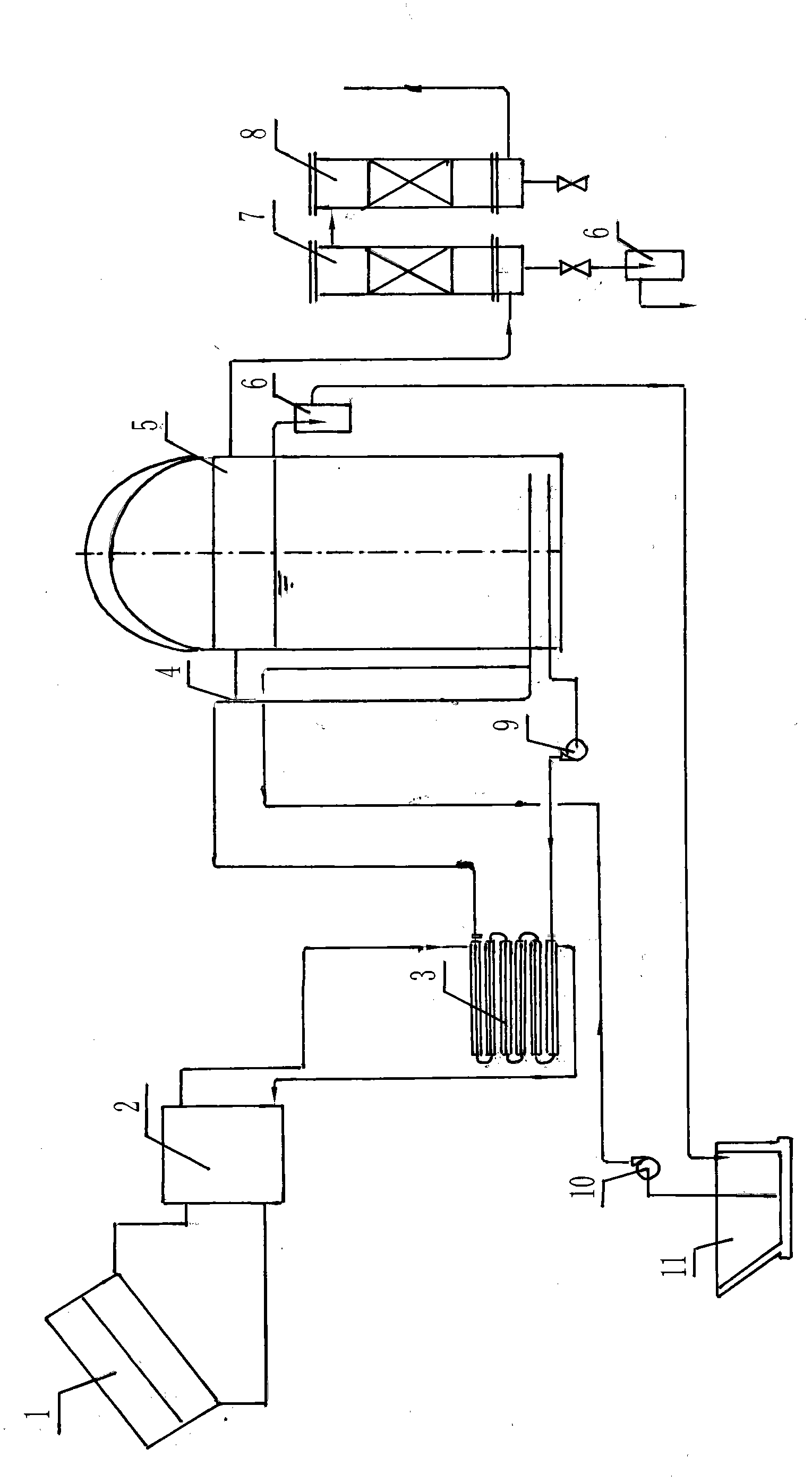

[0031] Example 1 with 20m 3 Take the jet reflux stirring biogas fermentation of the fermenter as an example.

[0032] Processing capacity: single or mixed livestock and poultry manure 400-800kg / day; fermentation TS: 5-8%; fermentation temperature: 33-37°C; fermentation period: 10-20 days; gas production: 20-40m 3 / day.

[0033] Breeding waste such as cow manure, pig manure, chicken manure, etc. pass through the coarse grid and the fine grid in turn, and use the fermentation liquid in the fermentation tank or tap water to prepare fermentation raw materials in the adjustment tank (10), and the feed concentration is controlled at 5 ~ 8%, sent into anaerobic fermentation tank (5) with feed pump (9). The raw material and the fermentation liquid at the bottom of the fermenter are pumped out by the circulation pump (8) and sent to the ejector (4), and the biogas is sucked in and fully mixed in the throat of the ejector. At the same time, heat the mixed fermented liquid with solar ...

Embodiment 2

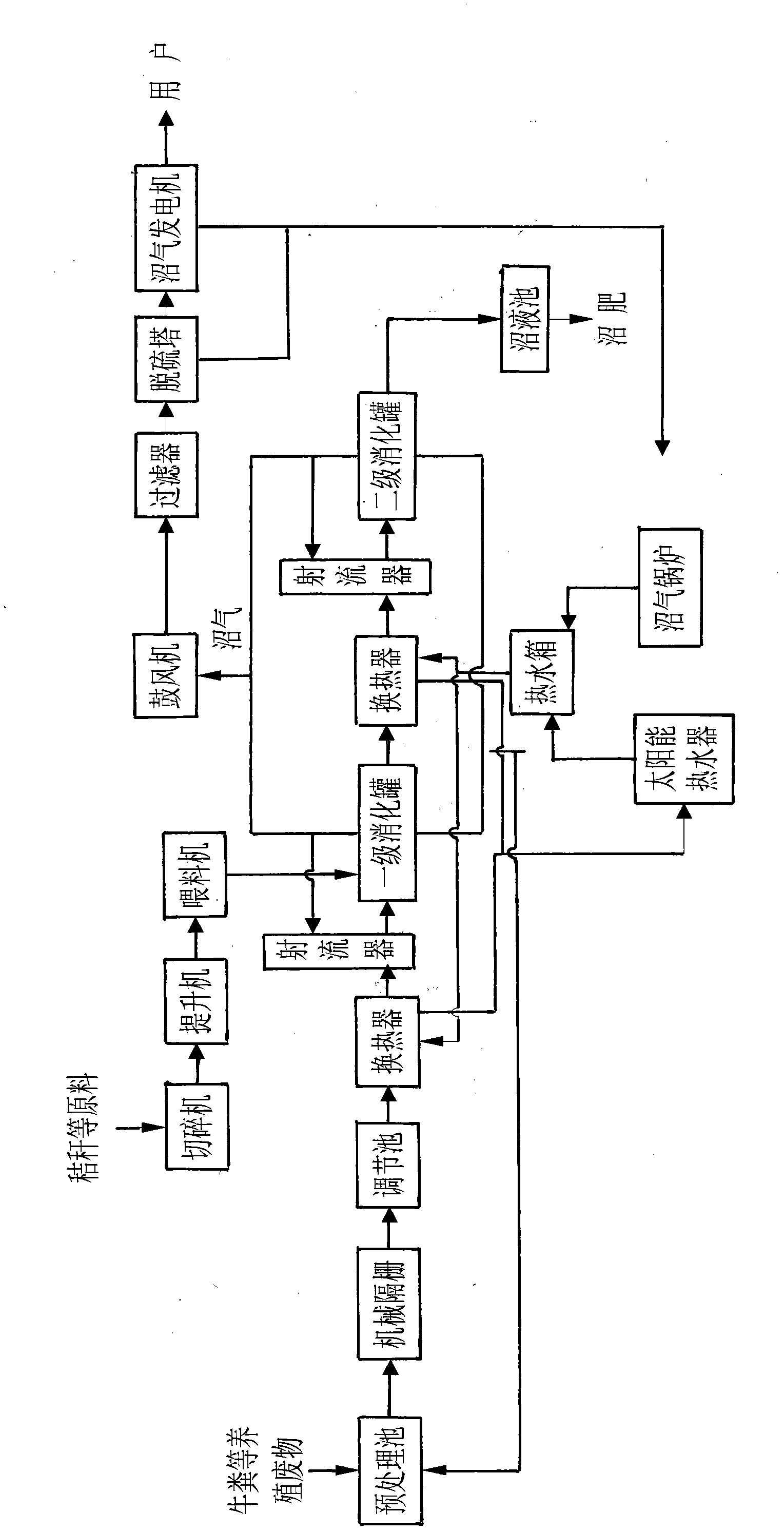

[0034] Example 2 with 100m 3 Take the jet reflux stirring biogas fermentation of the secondary fermentation of the fermenter as an example.

[0035] Processing capacity: livestock and poultry manure, green feed, etc. 10-15t / day, fermentation TS: 6-10%; fermentation temperature: 33-37°C; fermentation period: 10-20 days; gas production 200-350m 3 / day.

[0036] The manure from the farm flows to the pretreatment tank by itself through the drainage ditch or pours the manure collected from a distance by a dung truck into the pretreatment tank, and uses biogas water or tap water after anaerobic fermentation to prepare in the regulating tank (10) to maintain water balance , the feed concentration is controlled at 6-10%, mechanical grilles are arranged in sequence in front of the regulating tank (10), and after deployment, the manure passes through a mechanical grill to remove grass or other sundries in the manure, and then enters the regulating tank. An upper water pump (9) is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com