Temperature response water-soluble nonionic polyamino acid and preparation method thereof

A polyamino acid, non-ionic technology, applied in the field of water-soluble non-ionic polyamino acid and its preparation, can solve the problems of difficult biocompatibility and biodegradability, and achieves a simple and feasible synthesis method, low cost, The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of polyamino acid shown in embodiment 1, formula (II)

[0031]

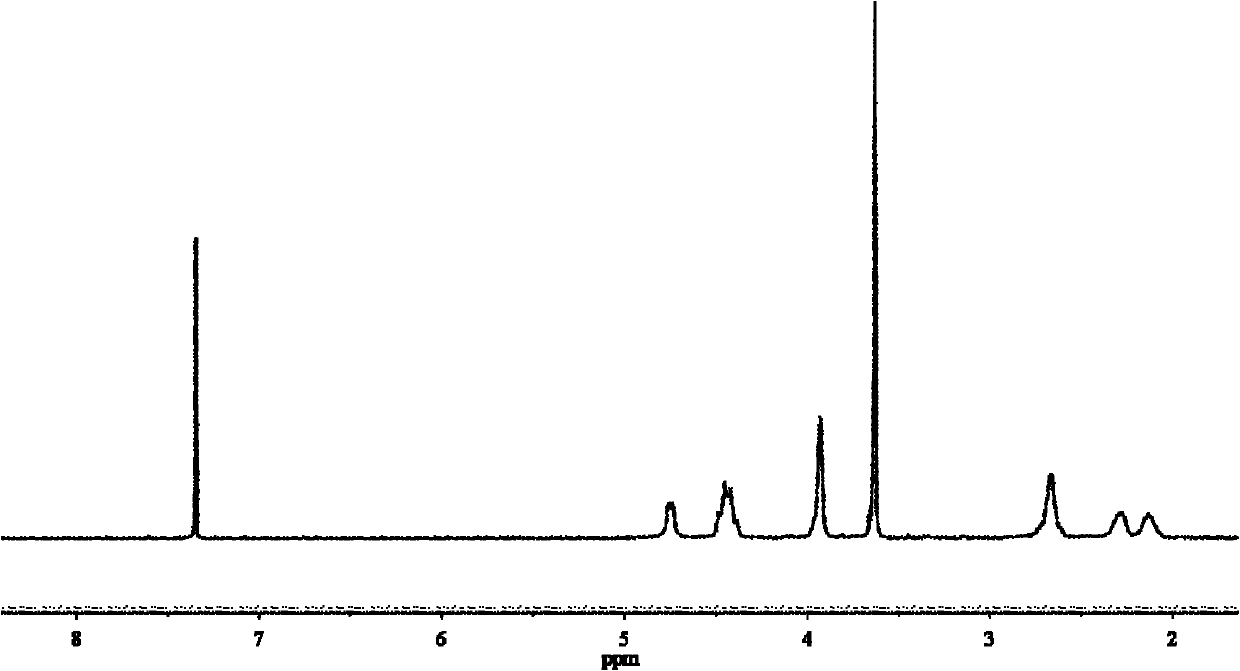

[0032] (1) first add 25 milliliters of ethylene glycol monomethyl ethers in the round bottom flask, and add 5 grams of glutamic acid, the mass and number ratio of glutamic acid and triethylene glycol monomethyl ether is 1: 4.8 in this system, Place the suspension in an ice-water bath, wait until it is cooled to 0°C, and slowly add 3 milliliters of concentrated sulfuric acid (wherein the ratio of glutamic acid to concentrated sulfuric acid is 1:1.1 by mass and number); return to 30 °C, react at 30 °C for 8 hours. The clear solution was poured into a mixed solution of triethylamine and isopropanol (1:10 by volume), resulting in a white precipitate. Centrifuged to obtain 3.8 grams of white solid, the productive rate was 54.5%; 1 H NMR (400MHz, D 2 O): δ4.30-4.23(t, 2H), 3.80-3.73(t, 1H), 3.72-3.66(t, 2H), 3.40-3.33(s, 3H), 2.66-2.49(m, 2H), 2.25-2.07(m, 2H); C NMR 13 C NMR (400MHz, D ...

Embodiment 2

[0035] The preparation of polyamino acid shown in embodiment 2, formula (III)

[0036]

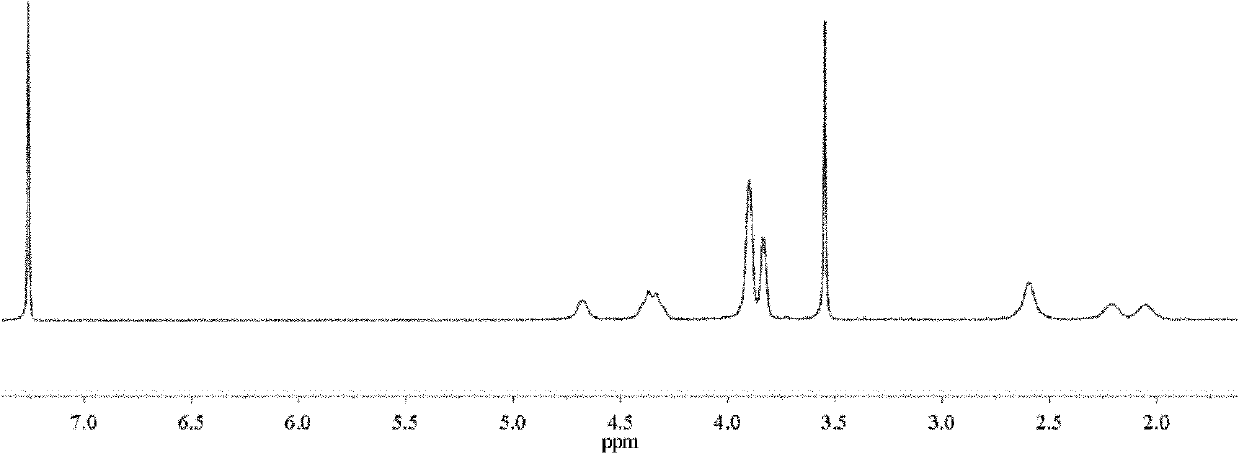

[0037] (1) First add 30 milliliters of diethylene glycol monomethyl ether in a round bottom flask, and add 5 grams of glutamic acid, the mass and number ratio of glutamic acid and diethylene glycol monomethyl ether in this system is 1: 6 , place the suspension in an ice-water bath, wait until it is cooled to 0°C, and slowly add 3 milliliters of concentrated sulfuric acid (wherein, the mass-number ratio of glutamic acid to concentrated sulfuric acid is 1:1.1), return to 20°C, react at 20°C for 48 hours. The clear solution was poured into a mixed solution of triethylamine and isopropanol (1:10 by volume), resulting in a white precipitate. Centrifuged to obtain 4.2 grams of white solid, the productive rate was 51.5%; 1 H NMR (400MHz, D2O): δ4.31-4.22 (t, 2H), 3.82-3.72 (m, 3H), 3.72-3.64 (m, 2H), 3.63-3.56 (m, 2H), 3.39-3.32 ( s, 3H), 2.66-2.49(m, 2H), 2.25-2.07(m, 2H); C NMR 13 C NMR ...

Embodiment 3

[0042] The preparation of polyamino acid shown in embodiment 3, formula (IV)

[0043]

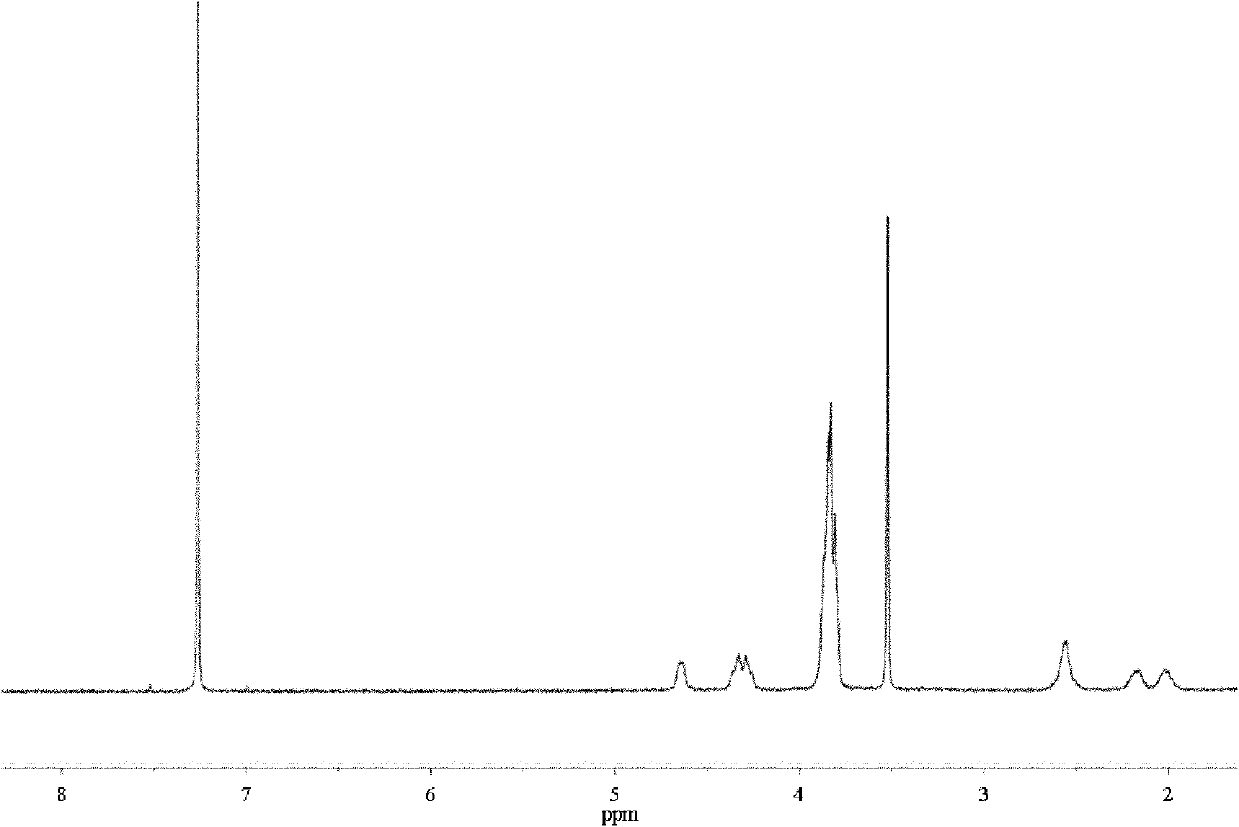

[0044] (1) First add 40 milliliters of triethylene glycol monomethyl ether in the round bottom flask, and add 5 grams of glutamic acid, the mass fraction ratio of glutamic acid and triethylene glycol monomethyl ether in this system is 1: 8 , place the suspension in an ice-water bath, wait until it is cooled to 0°C, and slowly add 3 milliliters of concentrated sulfuric acid (wherein the mass-number ratio of glutamic acid to concentrated sulfuric acid is 1: 1.1); return to 25°C, react at 25°C for 24 hours. The clear solution was poured into a mixed solution of triethylamine and isopropanol (1:10 by volume), resulting in a white precipitate. Centrifuged to obtain 3.7 grams of white solid, the productive rate was 37.1%; 1 H NMR (400MHz, D2O): δ4.32-4.25(t, 2H), 3.81-3.74(m, 3H), 3.73-3.64(m, 6H), 3.63-3.57(m, 2H), 3.40-3.33( s, 3H), 2.67-2.50(m, 2H), 2.23-2.07(m, 2H); C NMR 13 C NMR (400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com