Method for manufacturing anti-chloride polyamide reverse osmosis composite membrane with high flux

A reverse osmosis composite membrane, chloropolyamide technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc. The effect of improving adhesion, improving chlorine resistance, and improving chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

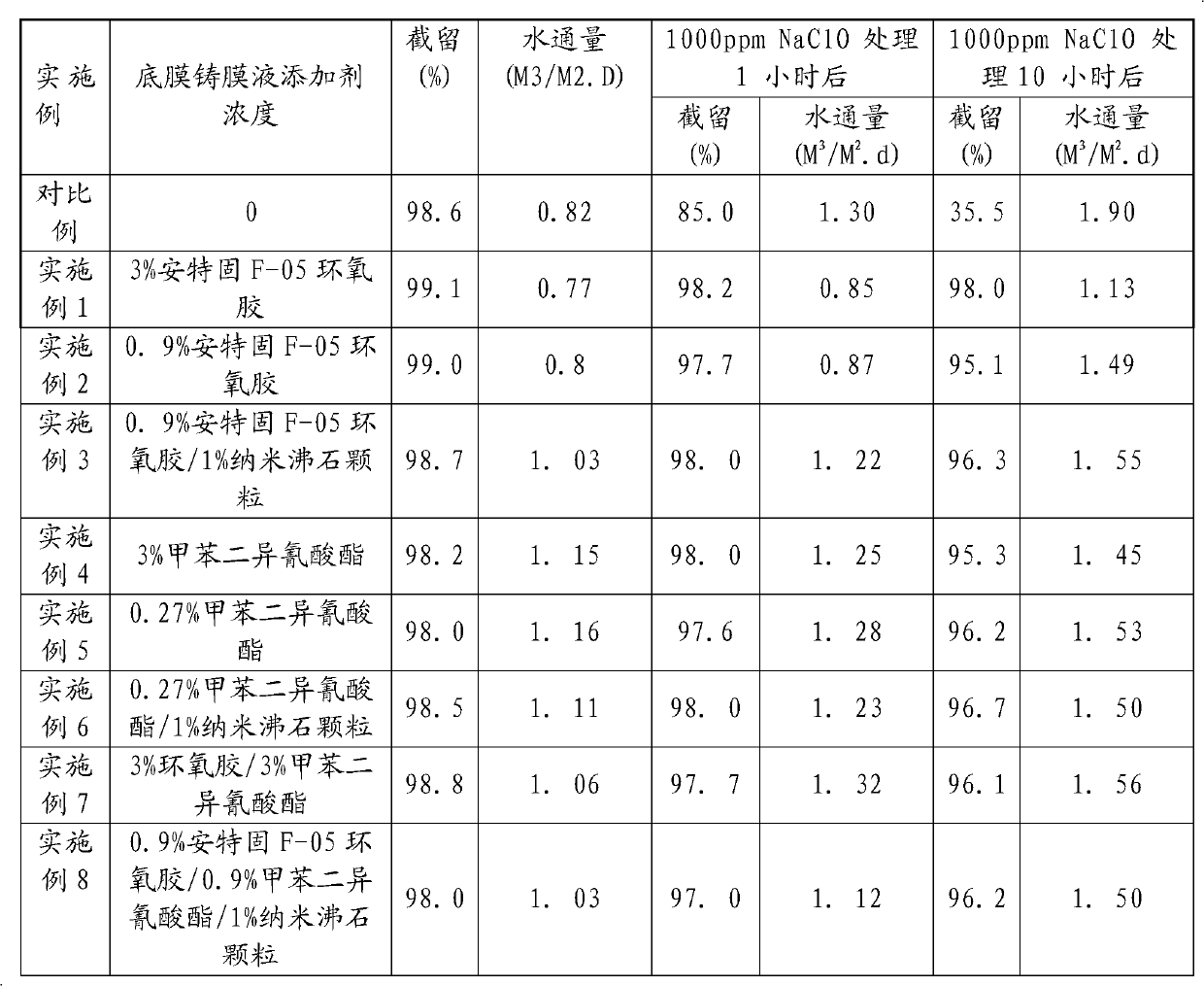

Embodiment 1

[0022] Embodiment 1, configuration concentration is 30% Antegu F-05 epoxy glue organic solution (solvent chooses dioxane), and this epoxy glue organic solution is added in the polysulfone-dimethyl sulfoxide solution And mix evenly, wherein, the concentration percentage of epoxy glue organic solution, polysulfone, dimethyl sulfoxide is 10%, 16%, 74% respectively, then use the same base film manufacturing process and composite process as in the comparative example to compound film forming. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. After soaking in 1000ppm NaClO aqueous solution for 10 hours, the retention rate of NaCl is still as high as 98.0%.

Embodiment 2

[0023] Embodiment 2, configuration concentration is 30% Antegu F-05 epoxy glue organic solution (solvent chooses dioxane), and this epoxy glue organic solution is added in the polysulfone-dimethyl sulfoxide solution And mix evenly, wherein, the concentration percentage of epoxy glue organic solution, polysulfone, dimethyl sulfoxide is 3%, 16%, 81% respectively, then use the same base film manufacturing process and composite process as in the comparative example to compound film forming. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. After soaking in 1000ppm NaClO aqueous solution for 10 hours, the retention rate of NaCl is still as high as 95.1%.

Embodiment 3

[0024] Embodiment 3, configuration concentration is 30% Antegu F-05 epoxy glue organic solution (solvent chooses dioxane), and this epoxy glue organic solution is added in the polysulfone-dimethyl sulfoxide solution And mix evenly, wherein, the concentration percentages of epoxy glue organic solution, polysulfone, and dimethyl sulfoxide are 3%, 16%, and 81% respectively, and then evenly disperse nano-zeolite particles into the casting liquid, add nano-zeolite The mass of the particles is 1% of the mass of the bottom film casting liquid, and the same bottom film manufacturing process and composite process as in the comparative example are used to compound the film. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. The water flux and chlorine resistance are both improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com