Preparation method of shearing thickened fluid based on SiO2 nano-scale microspheres

A micro-nano ball and fluid technology, applied in textile and paper making, fiber processing, fiber type, etc., can solve the problems of difficult-to-disperse particle aggregates, long preparation time, long preparation cycle, etc., and achieve simple process, stable product performance, The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

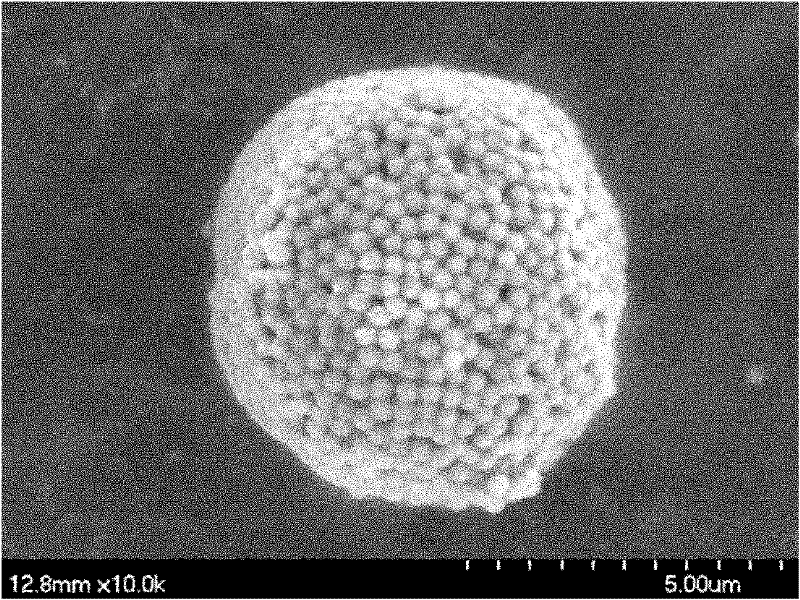

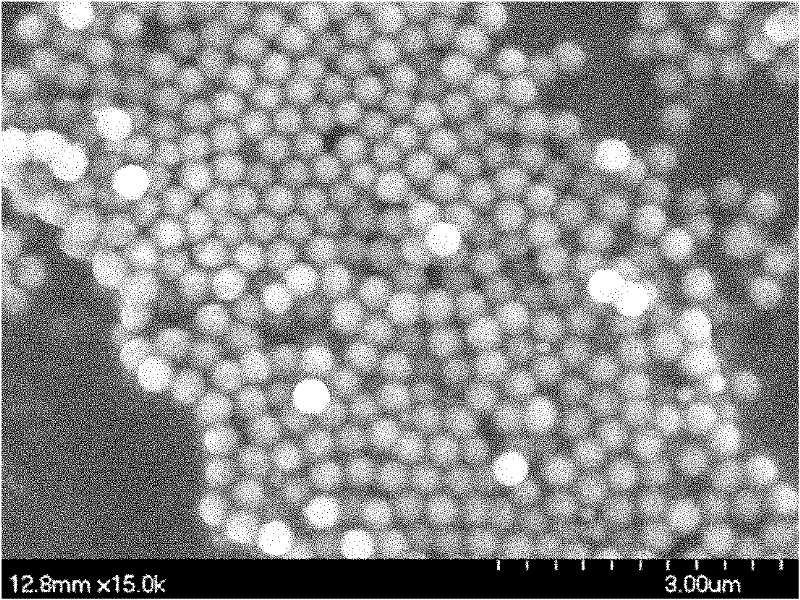

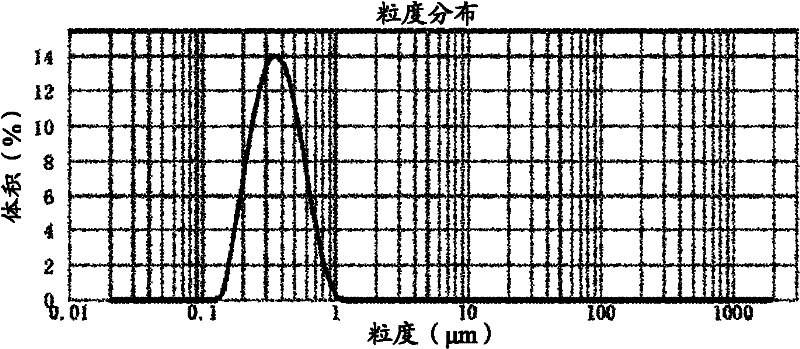

[0030] SiO 2 Preparation of the micro-nanosphere suspension: respectively configure an anhydrous ethanol solution with a molar concentration of tetraethyl orthosilicate of 0.8 mol / L as the first reaction solution, and a water molar concentration of 8 mol / L and an ammonia molar concentration of 1.6 mol / L L of absolute ethanol mixed solution, as the second reaction solution. Then control the reaction temperature of the microreactor to 30°C, and at the same time send the two reaction liquids into the microreactor in equal amounts, and fully mix the reaction in the microreactor, and the reaction product is SiO 2 micronanosphere suspension. And according to the needs, an appropriate amount of water and ammonia can be added to the obtained reaction product to keep the molar concentration of water at 8mol / L and the molar concentration of ammonia at 1.6mol / L. The first reaction solution with a molar concentration of ethyl acetate of 0.8mol / L continues to react, and finally obtains S...

Embodiment 2

[0032] First, according to the method of Example 1, SiO with a D50 particle size of 360nm was prepared. 2 micronanospheres. Use a ceramic microfiltration membrane with a filter pore size of 150 nm to first clean the SiO obtained by the reaction 2 The aqueous phase suspension of micronanospheres is washed until the pH of the filtrate=7. Then stop adding distilled water, and continue to use ceramic microfiltration membrane to filter out the water in the suspension to concentrate until the solid content of the suspension is 10%.

[0033] Then, step a: adding SiO to the concentrated suspension 2 The polyethylene glycol 200 liquid of 10% by weight of the micro-nano balls was treated with an ultrasonic stirring device for 30 minutes. Step b: Use spray drying equipment to control the inlet temperature at 220°C, the outlet temperature at 90°C, the compressed air pressure at 0.3MPa, and the suspension feed flow rate at 1.8L / min, carry out spray drying, and obtain SiO in the receiv...

Embodiment 3

[0037] At first, according to the method for embodiment 1, prepare the SiO that D50 particle size is 278nm 2 Micro-nano balls; use a ceramic microfiltration membrane with a filter pore size of 150nm to clean the SiO obtained by the reaction 2 The aqueous phase suspension of micronanospheres is washed until the pH of the filtrate=7. Then stop adding distilled water, and continue to use ceramic microfiltration membrane to filter out the water in the suspension to concentrate until the solid content of the suspension is 8%.

[0038] Then, step a: adding SiO to the concentrated suspension 2 Glycerol liquid with 15% weight of micro-nanospheres was treated with ultrasonic stirring equipment for 45 minutes. Step b: Spray the suspension treated in step a by using spray drying equipment, controlling the inlet temperature at 240°C, the outlet temperature at 100°C, the compressed air pressure at 0.4MPa, and the suspension feed flow rate at 2.0L / min. Dry to get SiO in the receiver 2 D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com