Acidic flux cored wire for ultralow-hydrogen low-temperature steel

A technology of flux-cored welding wire and low-temperature steel, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor low-temperature toughness, high hydrogen diffusion of deposited metal, etc., and achieve improved mechanical properties and small spatter , The effect of elongation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 Preparation of ultra-low hydrogen low temperature steel flux-cored welding wire

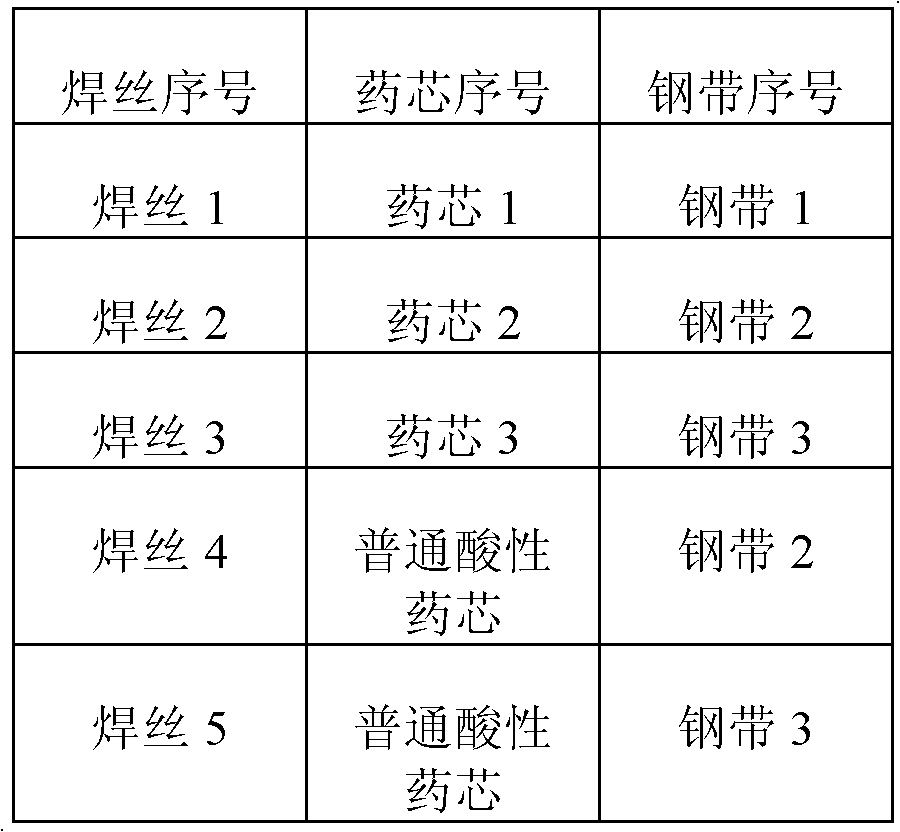

[0011] Flux-cored welding wire is prepared by a common manufacturing process: the powders of each component are passed through an 80-mesh sieve, and various powders are put into a powder mixer according to the proportion (Table 1) and stirred for 40 minutes, and then the mixed powder is added to the V-shaped steel strip (steel The strip composition is shown in Table 2) in the slot, the drug powder accounts for 16-17% of the total weight of the welding wire; the forming machine closes the strip slot; table 3).

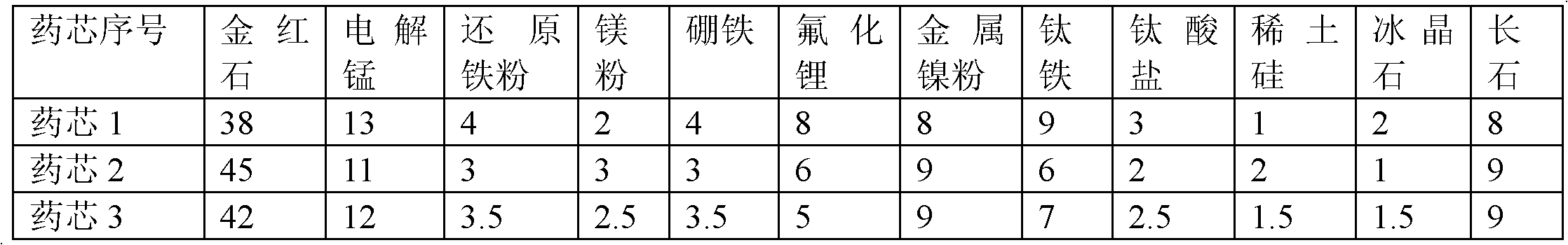

[0012] Table 1 Flux cored wire powder formula (mass percentage%)

[0013]

[0014] Table 2 steel strip composition (mass percentage %)

[0015] Strip serial number

C

Si

mn

P

S

Steel strip 1

0.05

0.04

1.3

0.015

0.015

0.03

0.02

3.5

0.006

0.006

Steel bel...

Embodiment 2

[0019] Embodiment 2 Flux cored wire performance test

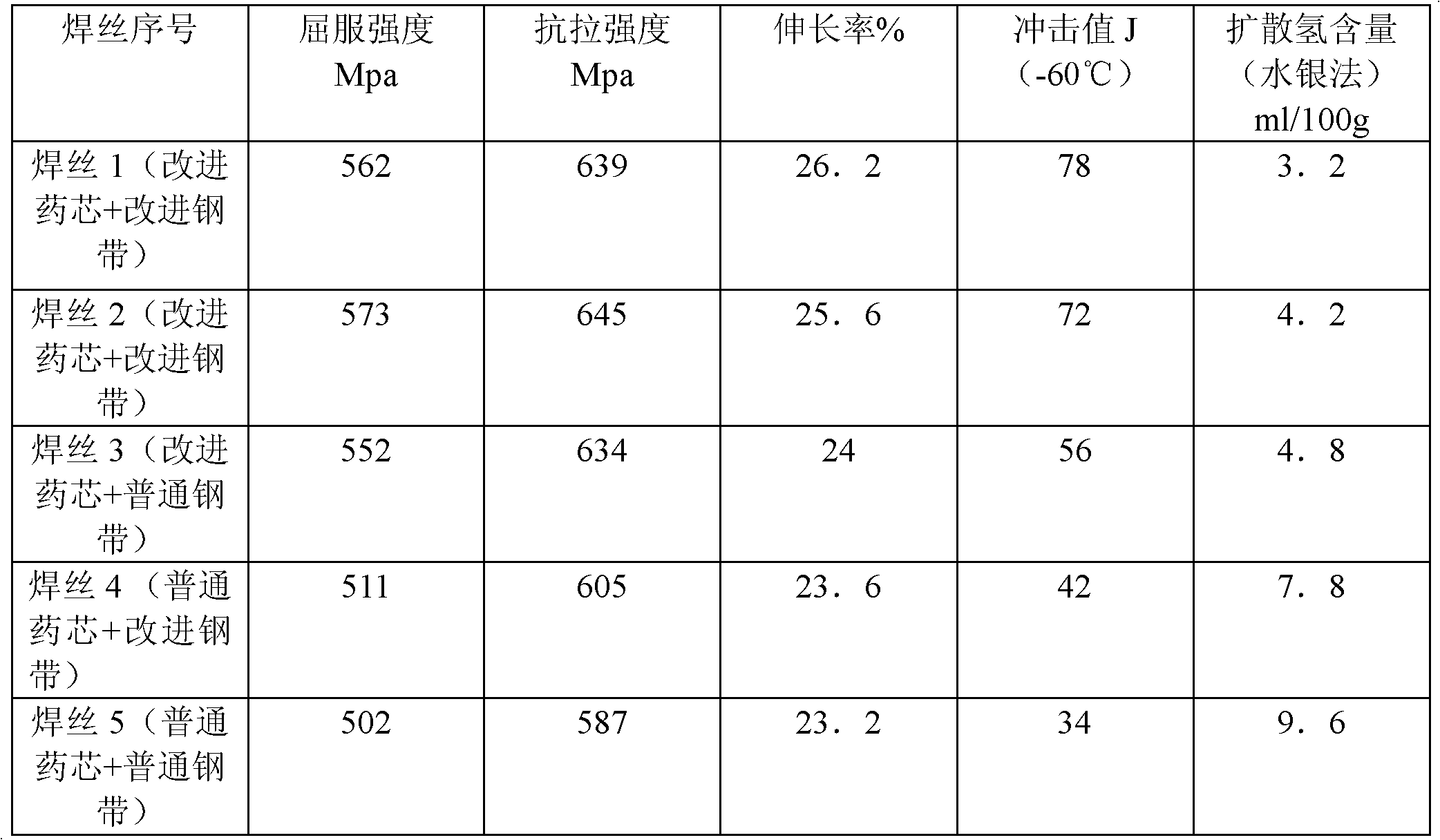

[0020] According to the GB / T 10045 testing method, test the performance indicators of the welding wire in Table 3, and the results are shown in Table 4:

[0021] Table 4 Performance indicators of different welding wires

[0022]

[0023] Experimental results show that the welding wire prepared by the acidic flux core of the present invention has low hydrogen content in the deposited metal diffusion, good low-temperature impact toughness of the weld seam, and improved elongation; the welding wire prepared by the steel strip of the present invention has yield strength, tensile strength, tensile strength The elongation is improved, the mechanical properties are greatly improved, and the low temperature impact toughness is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com