Supported photocatalyst with high activity under visible light and preparation method thereof

A photocatalytic material, visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic activity, difficult loading, etc., achieve simple preparation process, widen light response range, the effect of good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

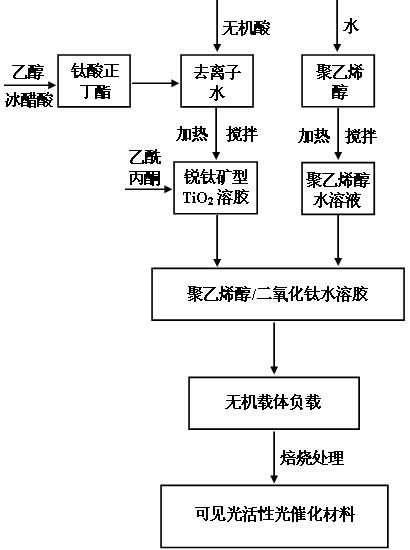

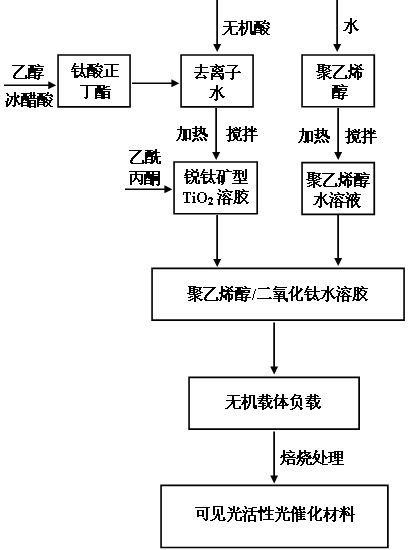

Method used

Image

Examples

Embodiment 1

[0022] First, add 0.1 parts of concentrated hydrochloric acid and 100 parts of distilled water into a reaction kettle equipped with a thermometer, a stirrer and a reflux condenser, raise the temperature to 70°C, add 5 parts of n-butyl titanate, 15 parts of absolute ethanol and 10 parts of The mixed solution of glacial acetic acid was reacted for 0.5h to obtain a translucent sol, which was further aged at room temperature for a certain period of time to obtain a bluish transparent TiO 2 Sol; take 20 parts of TiO 2 sol, add 0.5 part of acetylacetone, after stirring evenly, add 0.1 part of 15% PVA (polymerization degree 500, alcoholysis degree 99%) solution, continue stirring for 1 hour to get PVA / TiO 2 Sol; the PVA / TiO 2 The sol is coated on the inorganic carrier, dried at 70°C, and finally the carrier loaded with the catalyst is placed in a muffle furnace protected by an inert gas, heated to 300°C, and calcined for 1 hour to obtain the composite photocatalytic material.

Embodiment 2

[0024] First, add 0.5 parts of concentrated nitric acid and 150 parts of distilled water into a reaction kettle equipped with a thermometer, agitator and reflux condenser, raise the temperature to 50°C, add 10 parts of n-butyl titanate, 20 parts of absolute ethanol and 1 part of A mixed solution of glacial acetic acid was reacted for 2 hours to obtain a translucent sol, which was further aged at room temperature for a certain period of time to obtain a bluish transparent TiO 2 Sol; take 20 parts of TiO 2 Sol, add 1.0 parts of acetylacetone, after stirring evenly, add 5 parts of 5% PVA (polymerization degree 1700, alcoholysis degree 88%) solution, continue to stir for 2 hours to get PVA / TiO 2 Sol; the PVA / TiO 2 The sol is coated on the inorganic carrier, dried at 80°C, and finally the carrier loaded with the catalyst is placed in a muffle furnace protected by an inert gas, heated to 120°C, and calcined for 3 hours to obtain the composite photocatalytic material.

Embodiment 3

[0026] First, add 1 part of concentrated hydrochloric acid and 50 parts of distilled water into a reaction kettle with a thermometer, a stirrer and a reflux condenser, raise the temperature to 60°C, add 15 parts of n-butyl titanate, 5 parts of absolute ethanol and 5 parts of A mixed solution of glacial acetic acid was reacted for 5 hours to obtain a translucent sol, which was further aged at room temperature for a certain period of time to obtain a bluish transparent TiO 2 Sol; take 20 parts of TiO 2 Sol, add 0.05 parts of acetylacetone, after stirring evenly, add 20 parts of 1% PVA (polymerization degree 2400, alcoholysis degree 78%) solution, continue stirring for 1 hour to get PVA / TiO 2 Sol; the PVA / TiO 2 The sol is coated on the inorganic carrier, dried at 60°C, and finally the carrier loaded with the catalyst is placed in a muffle furnace protected by an inert gas, heated to 200°C, and calcined for 6 hours to obtain the composite photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com