Polyurethane material surface-modified by polyethylene glycol and derivatives thereof as well as preparation method and application thereof

A polyurethane material and polyethylene glycol technology, applied in the field of polyurethane materials, can solve the problems affecting the performance of the material body, complicated equipment, and the time required for chemical reagent methods, etc., and achieve good industrialization and practical prospects, simple equipment, and improved surface biological properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

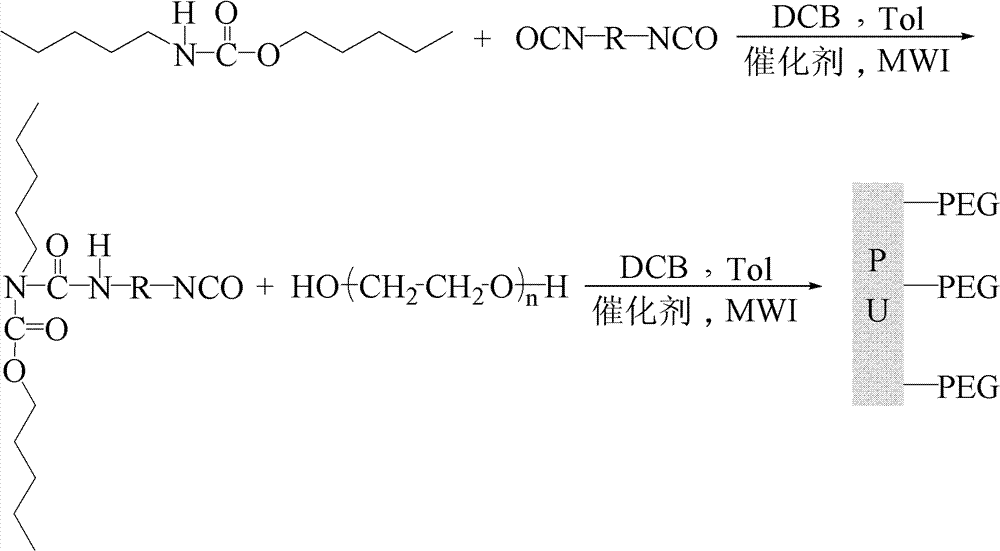

[0036] (1) Dissolve 0.50 g of diphenylmethane diisocyanate (MDI) in 10 mL of a mixed solvent of o-dichlorobenzene (DCB) and toluene (Tol) in a volume ratio of 4:6 to obtain solution A.

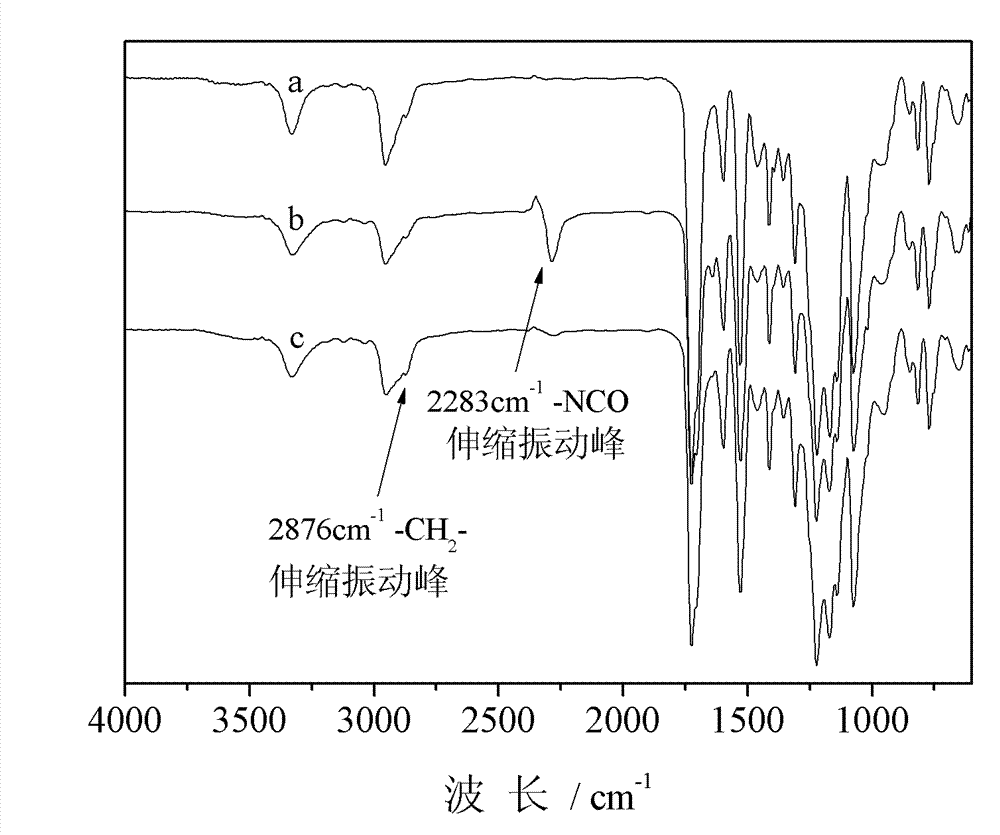

[0037] (2) Set the area to 20cm 2Immerse the polyurethane material in 10mL solution A, add catalyst triethylamine (TEA) 0.25g, place in microwave field, under 100W microwave irradiation power, react 10min, take out, wash, dry, obtain PU-NCO product (namely PU-MDI), the -NCO content per unit area measured by the acetone-di-n-butylamine titration method is 125 × 10 -8 mol cm -2 (Xiong Jun, Sun Fang, Du Hongguang. Determination of isocyanate groups in polyurethane by acetone-di-n-butylamine titration. Analytical Laboratory, 2007, 26 (8): 73-76), its surface total reflection infrared spectrum is shown in the appendix figure 1 Spectrum b and spectrum a are polyurethane materials. Compared with the spectrum of polyurethane material (spectrum a), the 2287cm of spectrum b -1 The stretching vibrati...

Embodiment 2

[0041] (1) Dissolve 1.00 g of hexamethylene diisocyanate (HDI) in 20 mL of a mixed solvent of o-dichlorobenzene (DCB) and toluene (Tol) in a volume ratio of 8:2 to obtain solution A.

[0042] (2) Set the area to 40cm 2 The polyurethane material is immersed in 20mL solution A, and 0.20g of catalyst stannous octoate is added. Place in a microwave field, and react for 5 minutes under 75W microwave irradiation power. Take out, wash, dry, obtain PU-NCO product, the -NCO content of its unit area is 50 * 10 -8 mol cm -2 .

[0043] (3) Add 0.50g (1.25×10 -3 mol) polyethylene glycol (PEG400) with a relative molecular mass of 400 was dissolved in 20 mL of a mixed solvent of o-dichlorobenzene (DCB) and toluene (Tol) at a volume ratio of 6:4 to obtain solution B.

[0044] (4) the area prepared by step (2) is 40cm 2 The PU-NCO product was immersed in 20mL of solution B, and 0.05g of the catalyst stannous octoate and 0.10g of triethylenediamine (TEDA) were added. Place in a microwave...

Embodiment 3

[0046] (1) Add 0.50g (2.5×10 -4 mol) monomethoxypolyethylene glycol (mPEG2000) with a relative molecular mass of 2000 was dissolved in 10 mL of a mixed solvent of o-dichlorobenzene (DCB) and toluene (Tol) at a volume ratio of 1:9 to obtain solution B.

[0047] (2) the area prepared by embodiment 1 step (2) is 20cm 2 The PU-NCO product was immersed in 10 mL of solution B, and 0.10 g of catalyst stannous octoate and 0.05 g of triethylenediamine (TEDA) were added. Place in a microwave field, and react for 10 minutes under 100W microwave irradiation power. Take out, wash and dry to obtain PU-MDI-mPEG2000 product. Adopt the acetone-di-n-butylamine titration method to measure the change of -NCO content after the reaction, draw the mPEG2000 graft content of its unit area to be 107 * 10 -8 mol cm -2 , the grafting rate reaches 86%. Through in vitro testing, the amount of fibrinogen adsorption of mPEG2000-modified PU is 85% lower than that of unmodified PU as measured by the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com