Sulfur-doped titanium dioxide nano-tube film loading indium-zinc-silver-sulfide solid solution, its preparation method and application

A technology of titanium dioxide and indium zinc sulfide, which is applied in chemical instruments and methods, catalysts for physical/chemical processes, hydrogen production, etc., can solve the problems that indium zinc sulfide silver solid solution is difficult to immobilize, and it is difficult to realize sulfide ion doping, etc. Simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

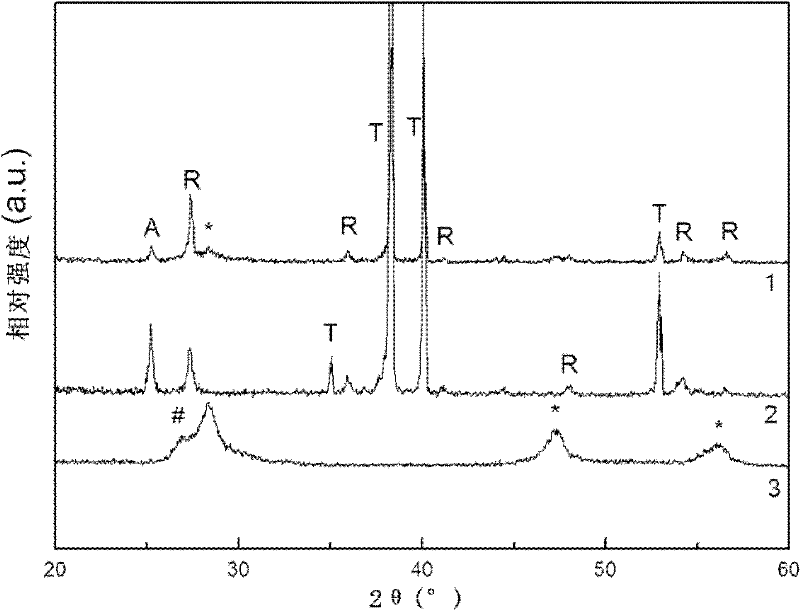

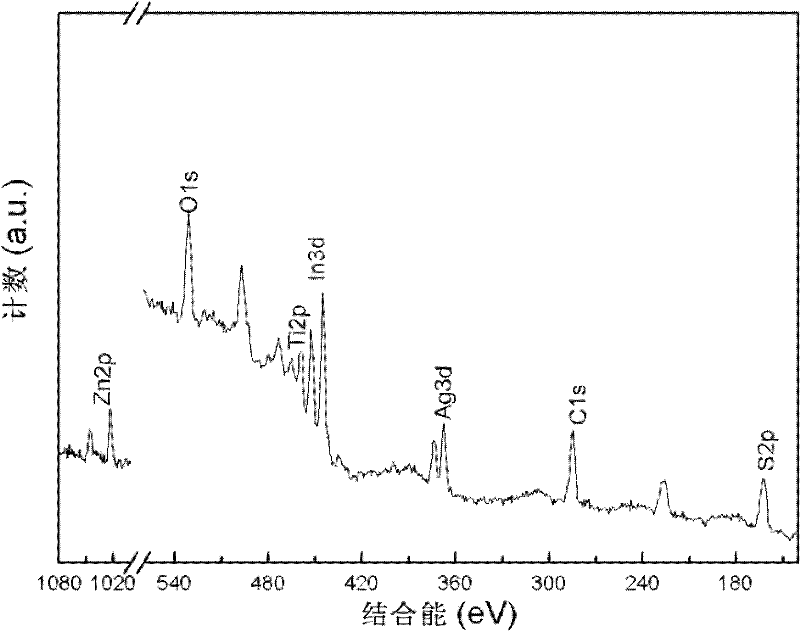

[0013] Specific embodiment one: this embodiment is a sulfur-doped titanium dioxide nanotube film loaded with indium zinc-silver sulfide solid solution, which is based on a titanium sheet, and a cubic phase sphalerite structure diffraction peak appears at the 28.35° position of the X-ray diffraction spectrum. A pair of O-Ti-S signal peaks appear at the positions of 163.78eV and 164.96eV in the X-ray photoelectron spectrum of S2p, and the Raman spectrum is at 337cm -1 A appears at the Raman shift 1g Mode Ti-S bond Raman vibration peaks.

[0014] The sulfur-doped titanium dioxide nanotube film loaded with indium zinc-silver sulfide solid solution in this embodiment is abbreviated as ZnS-In 2 S 3 -Ag 2 S@TiO 2 NTs film.

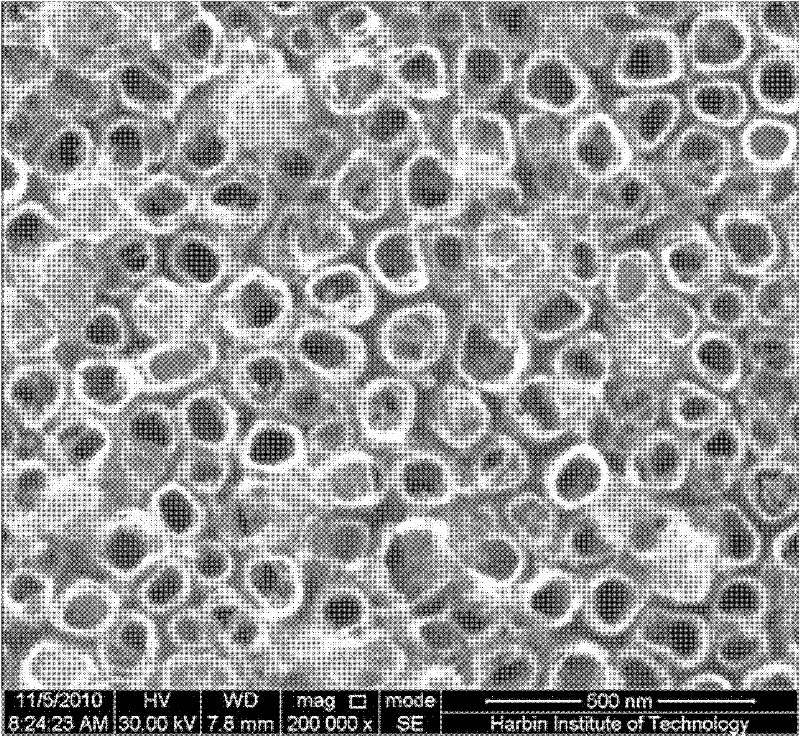

[0015] ZnS-In of the present embodiment 2 S 3 -Ag 2 S@TiO 2 Scanning electron micrographs of NTs films, such as figure 1 As shown, the surface of the sulfur-doped titanium dioxide nanotube film is loaded with acicular indium-zinc-silver sulfide solid solu...

specific Embodiment approach 2

[0022] Specific embodiment two: this embodiment is the preparation method of the sulfur-doped titanium dioxide nanotube thin film loaded with indium zinc silver sulfide solid solution as described in specific embodiment one, and it is realized through the following steps: 1. Adopt anodic oxidation method on titanium Prepare the titanium dioxide nanotube film on the chip; 2. Put the titanium dioxide nanotube film prepared in step 1 into the reaction kettle, then put the reaction solution into the reaction kettle, make the reaction solution submerge the titanium dioxide nanotube film, and then add the titanium dioxide nanotube film to the reaction solution Pass the inert gas for 10-30 minutes, then seal the reaction kettle; 3. Place the sealed reaction kettle in step 2 at 160-200°C, keep it warm for 10-20 hours, then cool to room temperature, take out the titanium dioxide nanotube film, and carry out Cleaning and drying, that is, the preparation of the sulfur-doped titanium dioxi...

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the specific steps of step one are: pretreating the titanium sheet to remove the surface oxide film, and then placing the pretreated titanium sheet in the electrolyte as a working electrode , the copper sheet is used as the counter electrode, the reaction voltage is controlled at 10-30V, and the constant-voltage anodization is carried out for 20-120 minutes, that is, the titanium dioxide nanotube film is obtained on the titanium substrate, and the electrolyte composition is: 5-6g / L NaF and volume Concentration of 2% to 5% H 3 PO 4 solution, the solvent is water. Other steps and parameters are the same as in the second embodiment.

[0025] The scanning electron micrograph of the titanium dioxide nanotube thin film prepared by the present embodiment is as follows Image 6 as shown,

[0026] In this embodiment, the specific operation of pretreating the titanium sheet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com