Preparation method of organic-inorganic hybrid monolithic capillary column

A capillary monolithic column and organic technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of few types of organosilanes, long reaction time, high cost, etc., and achieve uniform pore size distribution and simple preparation process , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Column pretreatment

[0026] First rinse the empty capillary column with 0.1mol / L HCl solution for about 1h, then rinse with deionized water for 30min, then rinse with 0.1mol / L NaOH for 4h, then rinse with deionized water for 30min, and finally rinse with methanol for 30min, nitrogen Blow dry and set aside.

[0027] 2. Silanization

[0028] Inject a mixture of anhydrous methanol and methacryloxypropyltrimethoxysilane (γ-MAPS) at a volume ratio of 1:1 into the pretreated capillary, react at 60°C for 24h, then use methanol for 30min, Blow dry at 60°C with nitrogen.

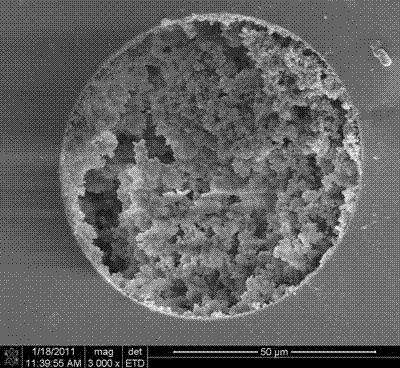

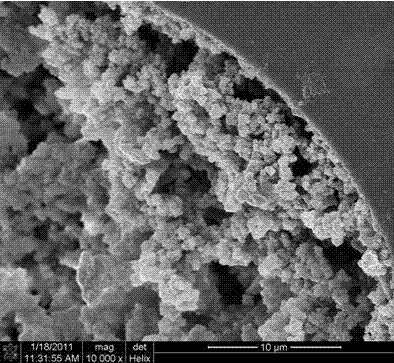

[0029] 3. In-column synthesis

[0030] Accurately weigh 38 mg polyethylene glycol 10000 (PEG 10000) into a round-bottomed flask, add 0.35 mL of 0.01 mol / L acetic acid, 132 μL of tetramethoxysilane (TMOS), and 22 μL of γ-MAPS in ice Vigorously stirred for 1 h in a water bath, the mixture was transparent and viscous. Add 20 mg of 4-vinylphenylboronic acid (VPBA), 80 μL of diethylene glycol and 1 mg of a...

Embodiment 2

[0034]Accurately weigh 38 mg PEG 10000 into a round-bottomed flask, add 0.35 mL of 0.01 mol / L acetic acid, 132 μL of TMOS, and 44 μL of vinyltrimethoxysilane (VTMS), respectively, and vigorously stir for 1 h in an ice-water bath. The mixture was transparent and viscous. Add 12.5 mg of VPBA, 10 μL of acetone and 1 mg of AIBN to the above mixture, and repeatedly sonicate and vortex for 20 minutes (prevent overheating of the sonicated water during sonication) until the mixture is completely dissolved. The viscous mixture was injected into a silanized capillary with an inner diameter of 75 μm to a point of 25 cm, both ends were sealed and placed in a water bath at 45 °C for 12 h, then transferred to a water bath at 75 °C for another 12 h. After the reaction, it was taken out and cooled to room temperature, and washed with 100% methanol at a low flow rate for 40 min with a high-pressure constant-flow pump to remove unreacted functional monomers and some by-products generated by the...

Embodiment 3

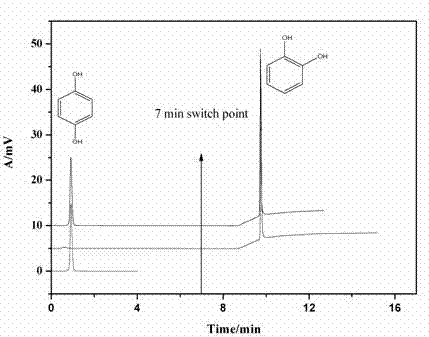

[0036] In micro-column liquid chromatography (μHPLC) mode, pH 8.0, ion concentration 20 mmol / L, acetonitrile: phosphate (30 / 70, v / v) buffer was used as mobile phase A, and the running time was 0-6 min ; pH 3.6, ion concentration 20 mmol / L, acetonitrile: acetate (30 / 70, v / v) buffer as mobile phase B, the running time starts from 7 min; pump flow rate is 0.05 mL / min; detection wavelength 214 nm; under the condition of mobile phase A, resorcinol (0.1 mg / mL) was not retained on the monolithic column but was eluted directly, while catechol with 1,2-cis structure (0.1 mg / mL) was adsorbed on the column due to the formation of reversible covalent bonds with boronic acid groups. When the mobile phase was switched to B conditions, catechol was eluted. The mixture of the two is efficiently and selectively separated on the organic-inorganic hybrid capillary monolithic column prepared in Example 1, and its chromatographic separation diagram is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com