Chromate-free surface-treated metal material

A metal material and surface treatment technology, applied in the metal material coating process, the device for coating liquid on the surface, the anti-corrosion coating, etc., can solve the problem of insufficient corrosion resistance, safety and hygiene can not be used, never provide hydrophobic-oleophobicity , pollution resistance, solvent resistance, alkali resistance, corrosion resistance, non-chromate surface treatment of metal materials, etc., to achieve the effect of excellent corrosion resistance and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

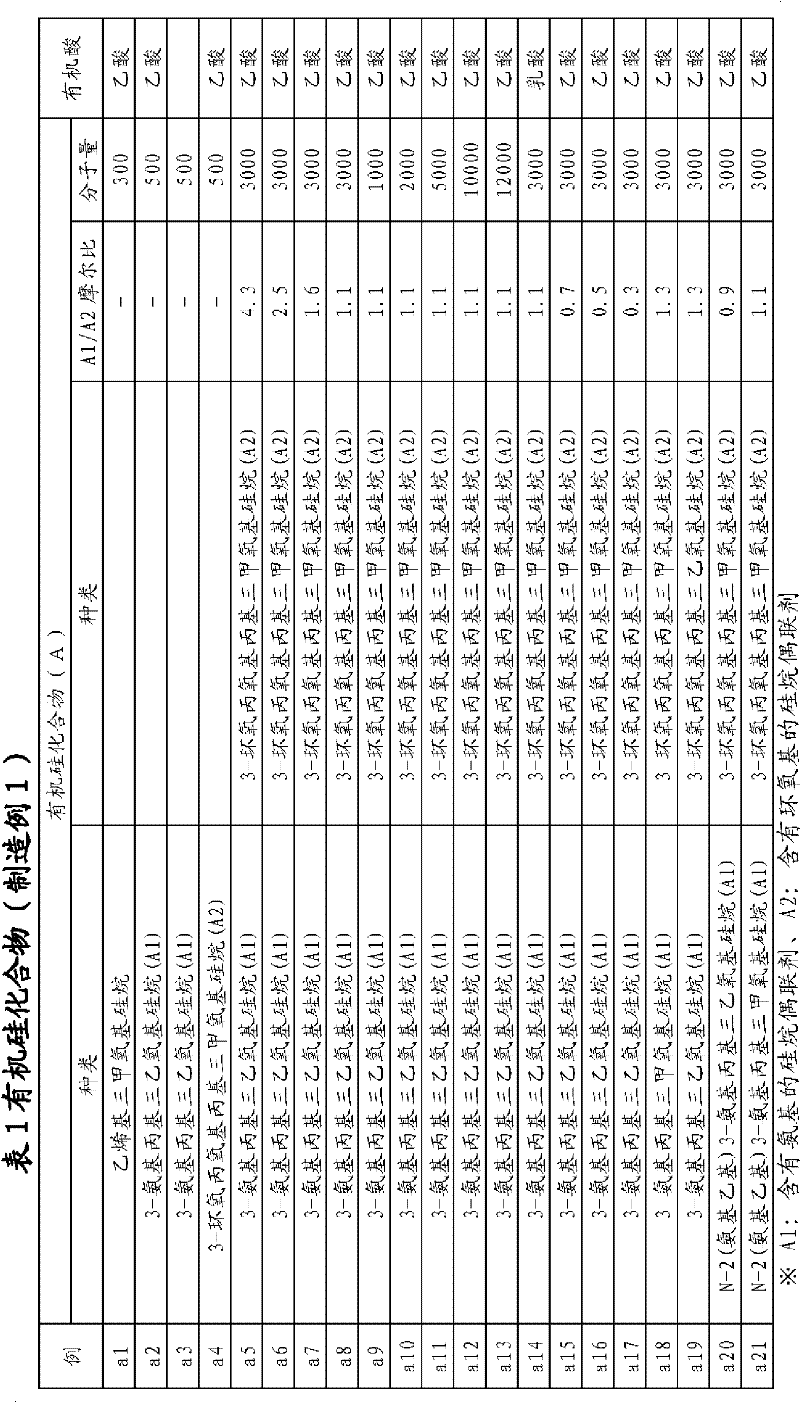

manufacture example 1

[0137] The organosilicon compound and organic acid shown in Table 1 were added to water, and stirred at normal temperature to obtain an organosilicon compound aqueous liquid having a solid content concentration of 10% by mass.

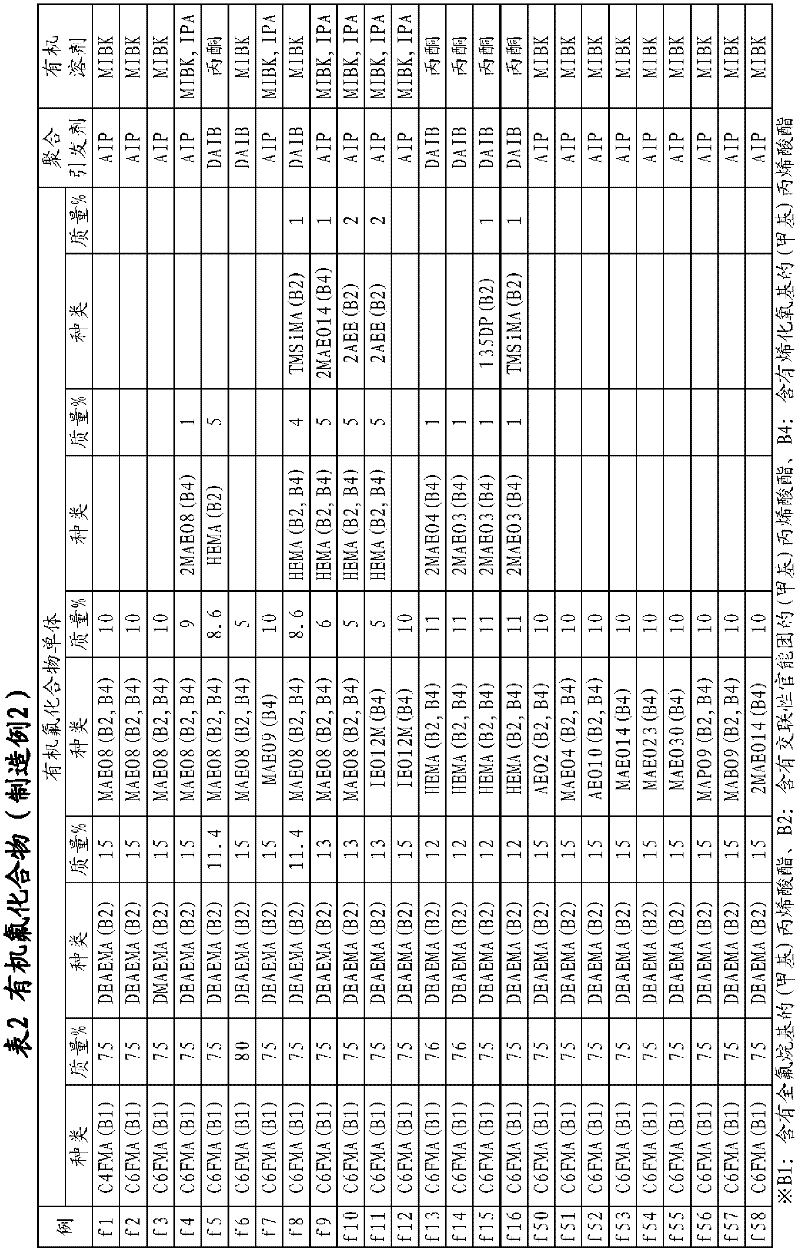

manufacture example 2

[0139] The monomers, polymerization initiators, and organic solvents shown in Table 2 were mixed and replaced with nitrogen, and then polymerized while stirring at 65° C. for 16 hours to obtain a polymer solution with a solid content concentration of 20% by mass. Water and acetic acid were added to the obtained polymer solution, and stirred for 15 minutes to perform emulsification and dispersion. After the organic solvent was distilled off at 65° C. under reduced pressure, water was added so that the solid content concentration became 20% by mass, and an aqueous dispersion of an organic fluorine compound was obtained. Abbreviations in Table 2 have the following meanings.

[0140] C 4 FMA:CH 2 =C(CH 3 )COOC 2 h 4 C 4 f 9

[0141] C 6 FMA:CH 2 =C(CH 3 )COOC 2 h 4 C 6 f 13

[0142] DEAEMA: N,N-Diethylaminoethyl methacrylate

[0143] DMAEMA: N,N-Dimethylaminoethyl methacrylate

[0144] MAEO8:CH 2 =C(CH 3 ) COO (C 2 h 4 O) n H (average of n is 8)

[0145] 2M...

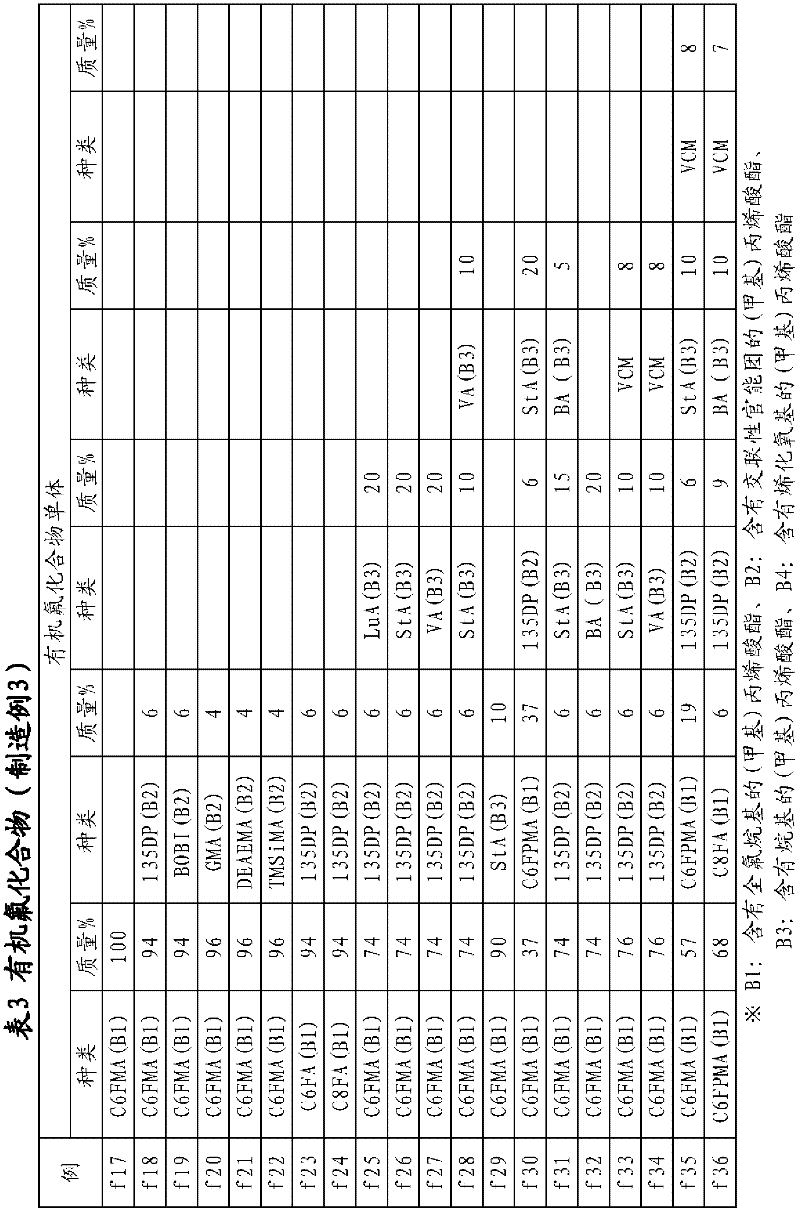

manufacture example 3

[0164] The monomer shown in Table 3, emulsifier (polyoxyethylene oleyl ether, polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, stearyl trimethyl ammonium chloride), dipropylene glycol, n-decyl Dioxanethiol was mixed into water and stirred at 56°C for 30 minutes to obtain a mixed solution. The obtained mixed solution was stirred under high pressure at 40 MPa while maintaining the temperature at 50° C. to obtain an emulsion. After cooling the obtained emulsion to below 30°C, carry out nitrogen substitution, add polymerization initiator 2,2'-azobis[2-(2-imidazolin-2-yl)propane], acetic acid, and stir in The polymerization reaction was carried out at 55° C. for 12 hours to obtain an organic fluorine compound aqueous liquid having a solid content concentration of 20% by mass. Abbreviations in Table 3 have the following meanings.

[0165] C 6 FMA:CH 2 =C(CH 3 )COOC 2 h 4 C 6 f 13

[0166] C 6 FA: CH 2 =CHCOOC 2 h 4 C 6 f 13

[0167] C 8 FA: CH 2 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com