Wollastonite fiber with large length-diameter ratio and preparation method thereof

A wollastonite fiber, high aspect ratio technology, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of high processing cost, complex production process, difficult operation, etc., to achieve stable product quality, simple production process, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

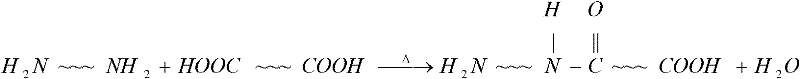

[0038] Preparation of cationic modifier:

[0039] That is, add 100 grams of water to the reaction kettle in advance, add 116 grams of hexamethylenediamine and 101 grams of adipic acid into the reaction kettle, stir at a speed of 120 rpm, raise the temperature to 60 ° C, and react for 3 hours to obtain adipic acid and hexamethylenediamine Salt, the salt is the cationic modifier.

Embodiment 2

[0041] Preparation of wollastonite fiber with high aspect ratio:

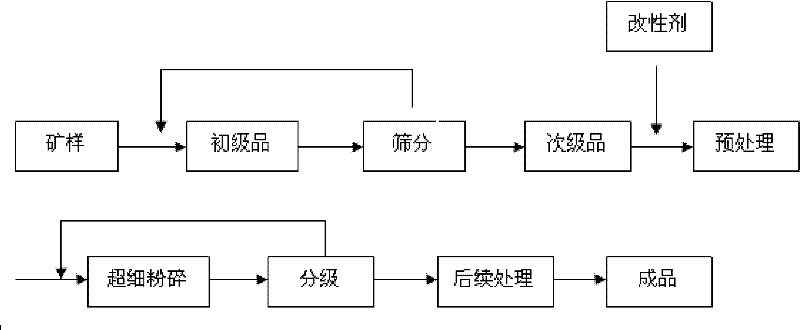

[0042] a) Screening process: crushing the ore sample to obtain a primary product, and screening the primary product to obtain a wollastonite secondary product with a particle size of 100-150 mesh;

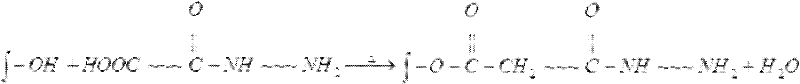

[0043] b) Treatment process: add cationic modifier in wollastonite secondary product, the weight ratio of cationic modifier and wollastonite secondary product is 1: 100, pretreated wollastonite secondary product , dried and dehydrated, then crushed to a particle size of 320-350 mesh, and classified according to the GB / T 1345-2005 standard;

[0044] c) Post-treatment process: analyze and test the graded wollastonite fibers, pack them into warehouses after passing the grade, and obtain cationic high-aspect-ratio wollastonite fiber products.

Embodiment 3

[0046] Except b) treatment process: adding a cationic modifier to the wollastonite secondary product, and the weight ratio of the cationic modifier to the wollastonite secondary product is 0.1:100, the rest is the same as that of embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com