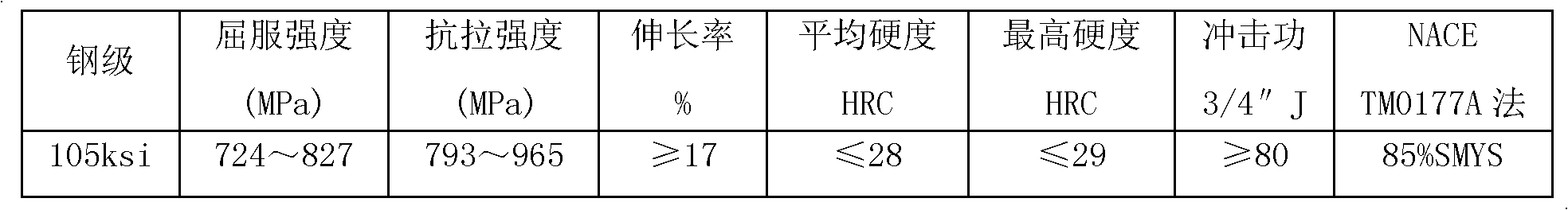

Method for manufacturing 105ksi steel grade sulfide stress corrosion resistant drill rod material

A 105ksi, stress corrosion technology, applied in the field of manufacturing 105ksi steel grade sulfide stress corrosion resistant drill pipe materials, can solve the problems of insufficient sulfide stress cracking resistance, unfavorable saving of precious metal resources, uneven structure of final products, etc. , achieve good anti-SSC performance, simple and easy-to-operate process, and excellent resistance to sulfide stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

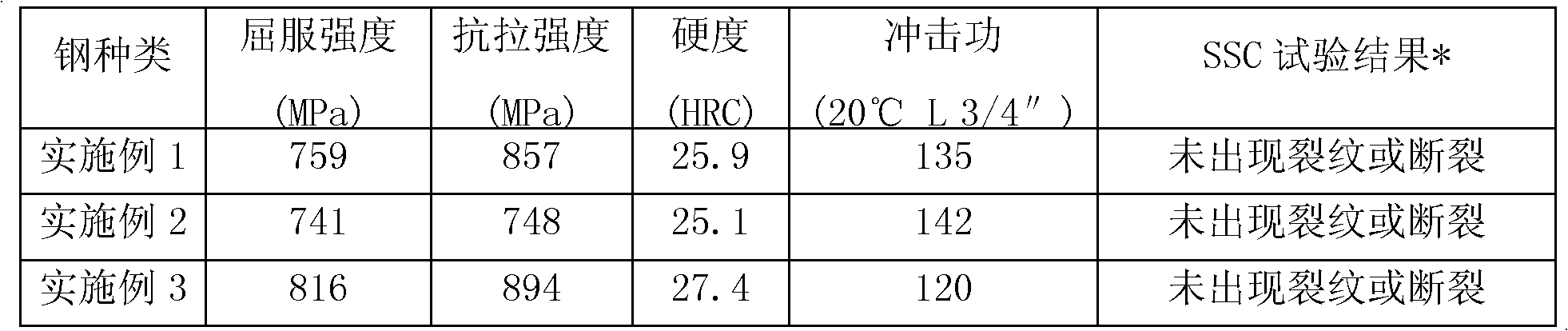

[0015] The manufacturing method of the 105ksi steel grade sulfide stress corrosion resistant drill pipe material of the present invention will be described in conjunction with the examples.

[0016] The invention adopts Cr-Mo alloy elements to realize excellent hardenability and SSC resistance. Its composition (mass percentage) is C 0.20~0.30%, Si 0.15~0.35%, Mn 0.40~0.70%, P≤0.015%, S≤0.005%, Cr 0.70~1.50%, Mo 0.50~0.80%, Nb 0~ 0.05%, V 0~0.06%, Ni≤0.20%, Ca≥0.0015%, the rest is Fe and unavoidable impurities.

[0017] Detailed chemical composition:

[0018] C: 0.20~0.30%

[0019] C is an important constituent element of low-alloy steel, and an important element for forming a tempered sorbite structure with fine carbide particles uniformly distributed after heat treatment. The reduction of C content is beneficial to improve the anti-SSC performance. In order to ensure the necessary strength of the steel pipe, the lower limit of C element content is 0.20%. The preferred co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com