Straw decomposing agent and production method thereof

A technology of straw decomposing agent and production method, which is applied in the direction of organic fertilizers, etc., and can solve the problem of symbiosis, intergrowth, and antagonistic effects of strains that do not fully consider the ability of strains to produce enzymes. Reasonable, poor stability of decomposing effect, etc., to achieve the effect of extending product shelf life, good promotion and use value, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

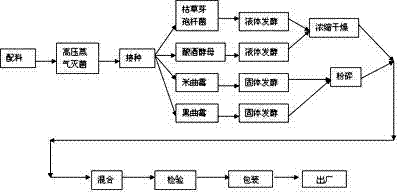

Image

Examples

Embodiment 1

[0098] Embodiment 1: A straw decomposing agent, characterized in that: the straw decomposing agent is prepared by mixing Bacillus subtilis, Saccharomyces cerevisiae, Aspergillus oryzae and Aspergillus niger, specifically as follows:

[0099] Step 1), preparing Bacillus subtilis:

[0100] A. Transfer the freeze-dried Bacillus subtilis strains to the pre-prepared test tube slope in a sterile environment, control the temperature at 30-32°C, cultivate for 36-40 hours, and then transfer to the eggplant bottle for 30- After 36 hours, after checking and confirming that there is no miscellaneous bacteria, it is used for fermenter inoculation;

[0101] B, preparation of culture medium material: the culture medium material in the fermenter needs to be proportioned according to the ratio of 0.5g of slag sugar, 0.5g of beef extract, 0.5g of protein jelly and 0.5g of sodium chloride per liter of water, mix and dissolve in water together, transported to the fermenter;

[0102] C. Steriliz...

Embodiment 2

[0130] Embodiment 2: other steps are identical with embodiment 1,

[0131] Step 5) Combine the raw Bacillus subtilis powder, cerevisiae parent powder, Aspergillus oryzae raw powder and Aspergillus niger raw powder obtained in the above steps: mix the raw Bacillus subtilis prepared in the above steps according to the number of grams 3 kilograms of powder, 2 kilograms of Saccharomyces cerevisiae powder, 2 kilograms of Aspergillus oryzae powder and 2 kilograms of Aspergillus niger powder were mixed uniformly to obtain the straw decomposing agent.

Embodiment 3

[0132] Embodiment 3: other steps are identical with embodiment 1,

[0133] Step 5) Combine the raw Bacillus subtilis powder, cerevisiae parent powder, Aspergillus oryzae raw powder and Aspergillus niger raw powder obtained in the above steps: mix the raw Bacillus subtilis prepared in the above steps according to the number of grams 3 kilograms of powder, 3 kilograms of Saccharomyces cerevisiae powder, 1 kilogram of Aspergillus oryzae powder and 2 kilograms of Aspergillus niger powder were uniformly mixed to obtain the straw decomposing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com