A kind of preparation method of glucosamine sulfate

A technology of glucosamine sulfate and bisulfate, which is applied in the field of electrochemical analysis and detection, can solve problems such as damage to the environment and workers' health, consumption of large organic solvents, and difficulty in stable production, so as to save costs, shorten reaction time, and improve catalytic performance. outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

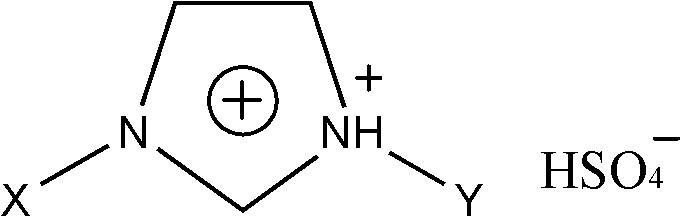

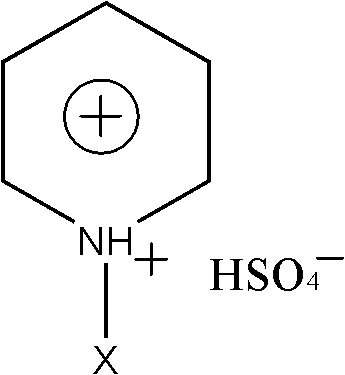

Method used

Image

Examples

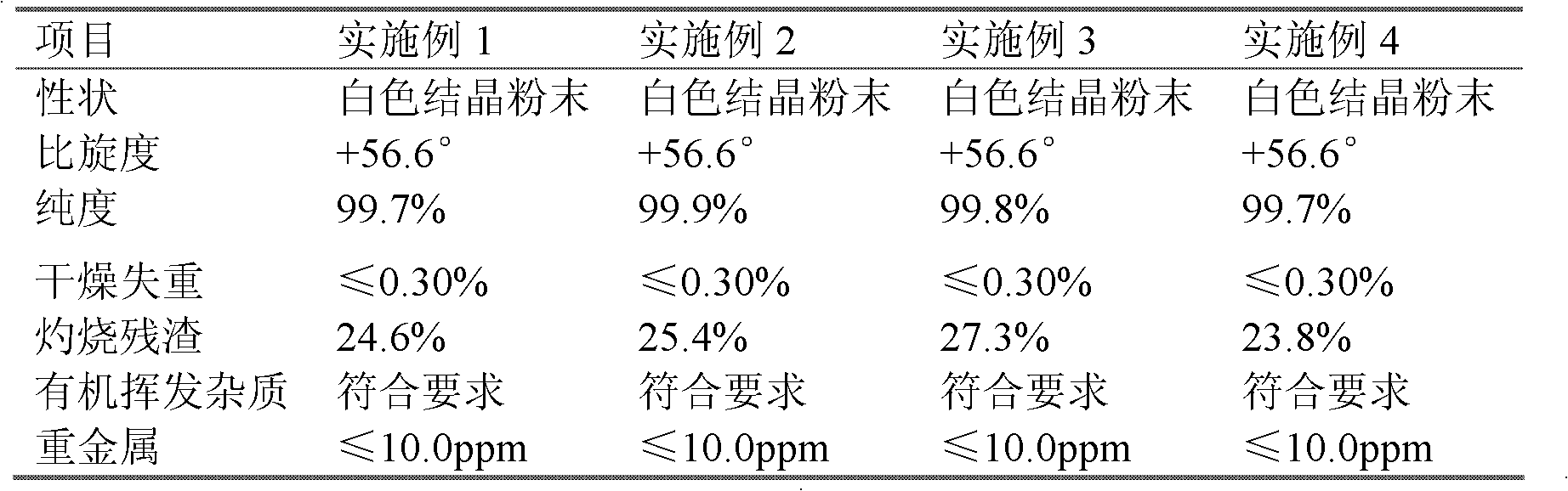

Embodiment 1

[0030] Weigh 10Kg of chitosan (Aladdin Reagent (Shanghai) Co., Ltd., specification: low viscosity), add 50 liters of 1-H-3-methylimidazolium bisulfate ionic liquid into the vacuum reactor, and heat up to about 55°C , start the stirring, open the feeding port, put the chitosan into it, and add 50Kg distilled water, gradually heat up and stir to make the chitosan dissolve, control the reaction temperature at 90°C, and keep the reaction time for 3.5 hours. After the hydrolysis was completed, 100 grams of activated carbon passed through a 100-mesh sieve was put in and decolorized at 80° C. for 1 hour. Transfer the decolorized feed liquid to a vacuum suction filter tank for suction filtration, then transfer the filtrate to a vacuum concentration kettle, control the temperature at 83°C, and concentrate to remove all water, add 3 times the volume of absolute ethanol to the concentrated liquid, Turn on the stirring and stir thoroughly for 1.5 hours, and let it stand at room temperatur...

Embodiment 2

[0034] Weigh 10Kg of chitosan, add 35 liters of 1-propylsulfonate-3-methylimidazolium bisulfate ionic liquid into the vacuum reactor, heat up to 60°C, start stirring, open the feeding port, and the chitosan Add sugar, and add 30Kg distilled water, gradually raise the temperature and stir to dissolve the chitosan, control the reaction temperature to 80°C, and keep the reaction time for 2.5 hours. After the hydrolysis was completed, 150 grams of activated carbon passing through a 100-mesh sieve was put into the mixture and decolorized at 85° C. for 1.5 hours. The decolorized feed liquid is transferred to a vacuum filtration tank for suction filtration, and the filtrate is then transferred to a vacuum concentration kettle, and the temperature is controlled at 93°C for concentration to remove all water. Add 3 times the volume of methanol to the concentrated solution, start the stirring and stir thoroughly for 1.5 hours, and let it stand at room temperature for 2 hours, crystalliza...

Embodiment 3

[0041] Weigh 10Kg of chitosan, add 40 liters of 1-butyl-3-methylimidazolium bisulfate ionic liquid into the vacuum reactor, heat up to about 55°C, start stirring, open the feeding port, and put chitosan into , and add 60Kg of distilled water, gradually increase the temperature and stir to dissolve the chitosan, control the reaction temperature to 100° C., and keep the reaction time for 2.0 hours. After the hydrolysis was completed, 50 grams of activated carbon passed through a 150-mesh sieve was put in and decolorized at 80° C. for 1.5 hours. The decolorized feed liquid is transferred to a vacuum filter tank for suction filtration, and the filtrate is then transferred to a vacuum concentration kettle, and the temperature is controlled at 80°C for concentration to remove all water. Add 2 times the volume of acetone to the concentrated solution, turn on the stirring and stir thoroughly for 1.5 hours, and let it stand at room temperature for 3 hours, crystals precipitate out, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com