A displacement chemical gold plating solution

An electroless gold plating and alloy technology, applied in the field of displacement electroless gold plating solution, can solve the problems of difficult control of electroless plating, harm to operators, influence on welding quality, etc., to avoid poor adhesion, good uniformity, and solder wettability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The test board used in this embodiment is an FR-4 substrate with a thickness of 2.0mm, the copper coverage area is about 15%, and the remaining part is coated with solder resist ink.

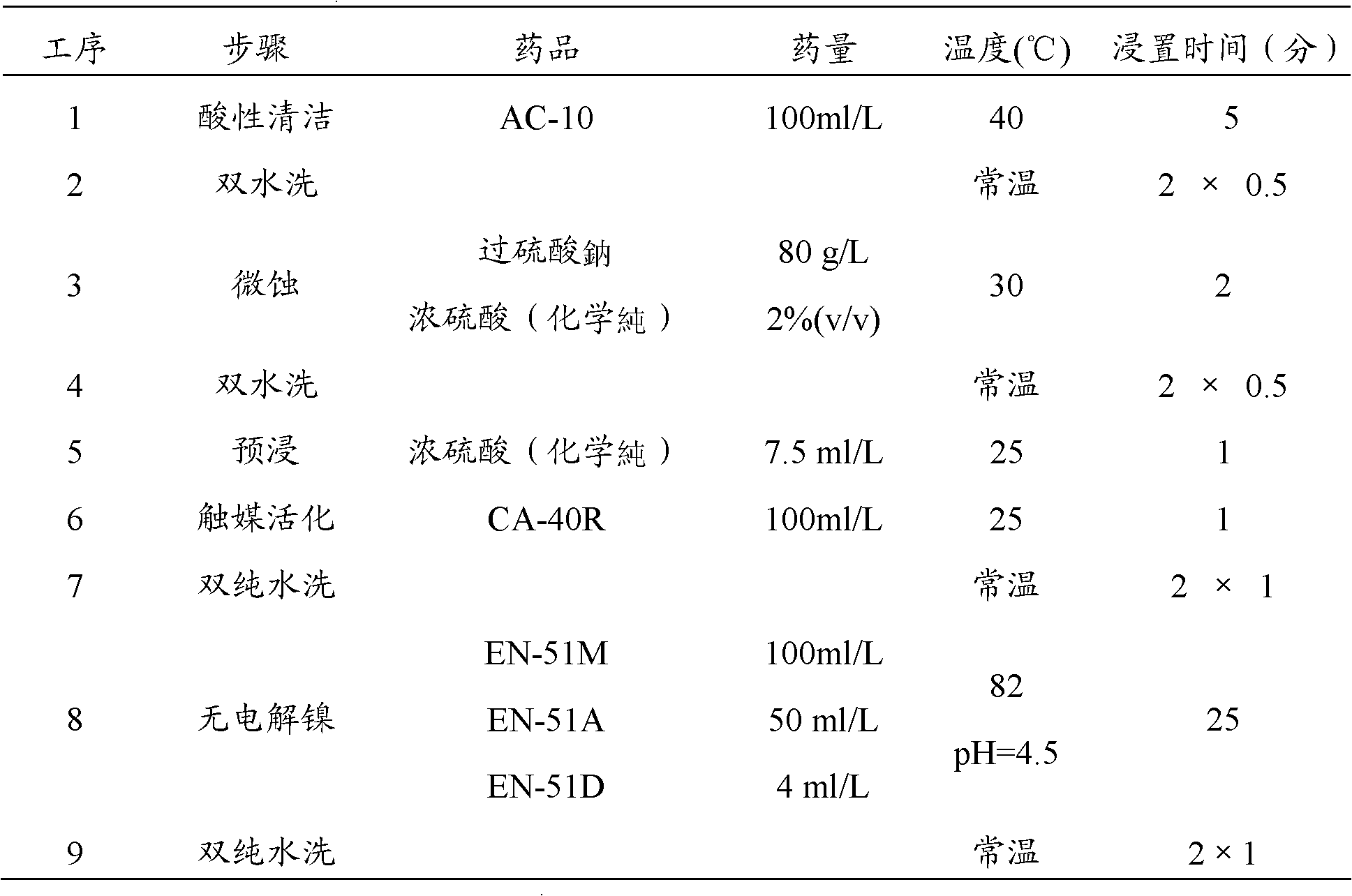

[0046] Pre-treatment steps: The test plate was pre-treated in the manner shown in Table 1, and the drugs used in the pre-treatment process were all products of Shenzhen Huaxun Applied Materials Co., Ltd. The plating time of electroless nickel plating is 25 minutes to form an electroless nickel thickness of 4 μm.

[0047] The test plate pretreatment process and condition that table 1 embodiment 1 adopts

[0048]

[0049] In a 500ml beaker, prepare the components and proportions shown in Table 2 to obtain a displacement type chemical gold plating solution. After adjusting the pH value to 5.2, heat the beaker to 86°C with a magnetic heating stirrer;

[0050] The substrate treated in the pretreatment step was washed with water, and immersed in the above-mentioned displacement chemical gol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com