A kind of water-soluble cutting oil and preparation method thereof

A water-soluble, cutting oil technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of non-ferrous metals, human skin damage, short trial period, etc., to achieve dirt resistance, surface tension reduction and cutting temperature, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

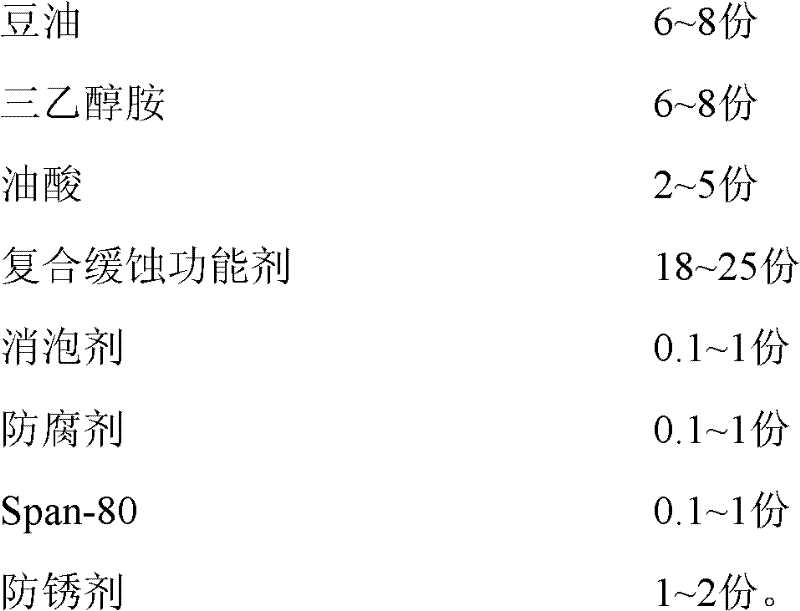

[0034] A water-soluble cutting oil base oil, its raw material components and parts by weight are respectively:

[0035]

[0036] in:

[0037] The antirust agent is a mixture of benzotriazole and ethylene glycol, and the weight ratio of benzotriazole to ethylene glycol is 1:10;

[0038] The nonionic surfactant is an octylphenol nonionic surfactant, and the HLB is between 6 and 10;

[0039] Composite corrosion inhibitor is 15% alcohol amine; 0.5% sodium EDTA; 10% sodium silicate; 5% sodium nitrite; 4% ethylene glycol, add water to 100%, percentage by weight;

[0040] The defoamer is an alkaline defoamer, and the defoamer commodity used in this embodiment is JF1240 of Tianjin Jinfeng Defoamer Co., Ltd., a mixture of silicone and polyether ester;

[0041] The preservatives are Grotan, forte, and the ingredients are hexahydrotriazine derivatives and sodium pyridinium thiol oxide.

[0042] A water-soluble cutting oil comprising the above-mentioned water-soluble cutting oil bas...

Embodiment 2

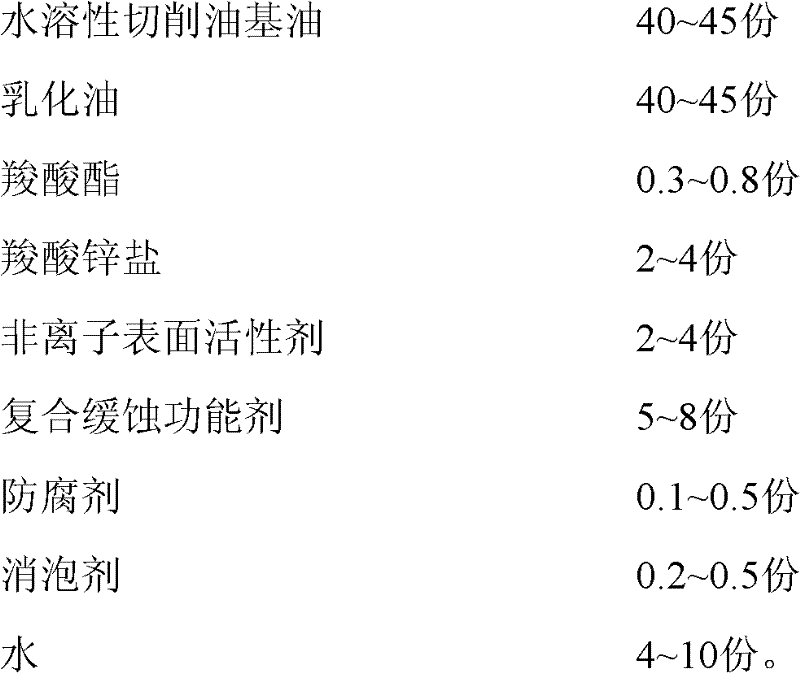

[0055] A water-soluble cutting oil base oil, its raw material components and parts by weight are respectively:

[0056]

[0057]

[0058] in:

[0059] The antirust agent is a mixture of benzotriazole and ethylene glycol, and the weight ratio of benzotriazole to ethylene glycol is 1:10;

[0060] The nonionic surfactant is an octylphenol nonionic surfactant with an HLB between 6 and 10;

[0061]Composite corrosion inhibitor is 15% alcohol amine; 0.5% sodium EDTA; 10% sodium silicate; 5% sodium nitrite; 4% ethylene glycol, add water to 100%, percentage by weight;

[0062] The defoamer is an alkaline defoamer, and the defoamer commodity used in this embodiment is JF1240 of Tianjin Jinfeng Defoamer Co., Ltd., and the main component is a mixture of silicone and polyether ester;

[0063] The preservative is Grotan, forte, and its main components are hexahydrotriazine derivatives and sodium pyridine-thiol oxide.

[0064] A water-soluble cutting oil comprising the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com