Lithium ion power cell and its preparation method

A power battery, lithium ion technology, applied in the field of lithium ion power battery and its preparation, can solve the problems of poor high temperature performance, difficult preparation, poor safety performance, etc., and achieves excellent rate charge and discharge, high volume specific energy, technology Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

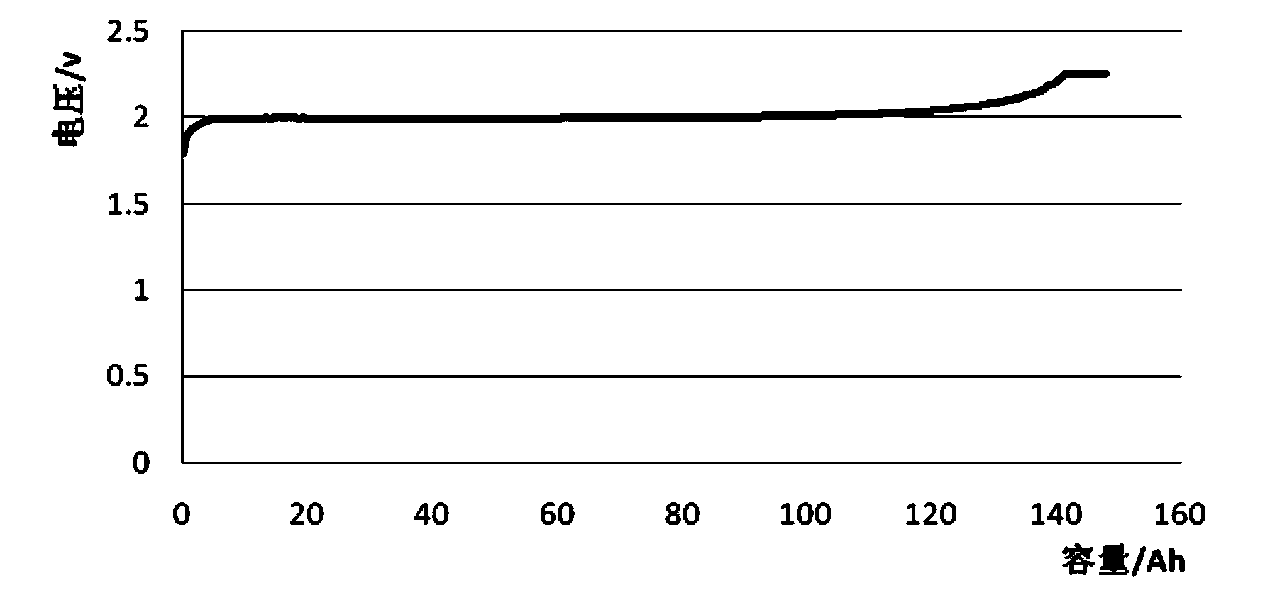

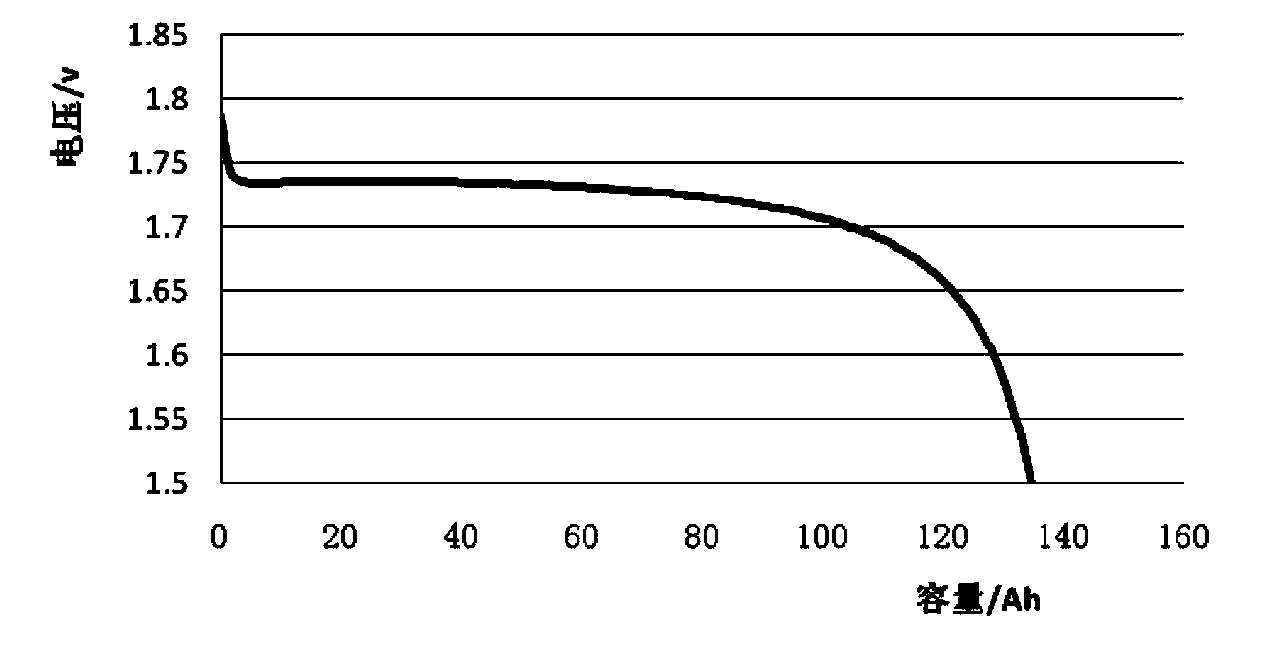

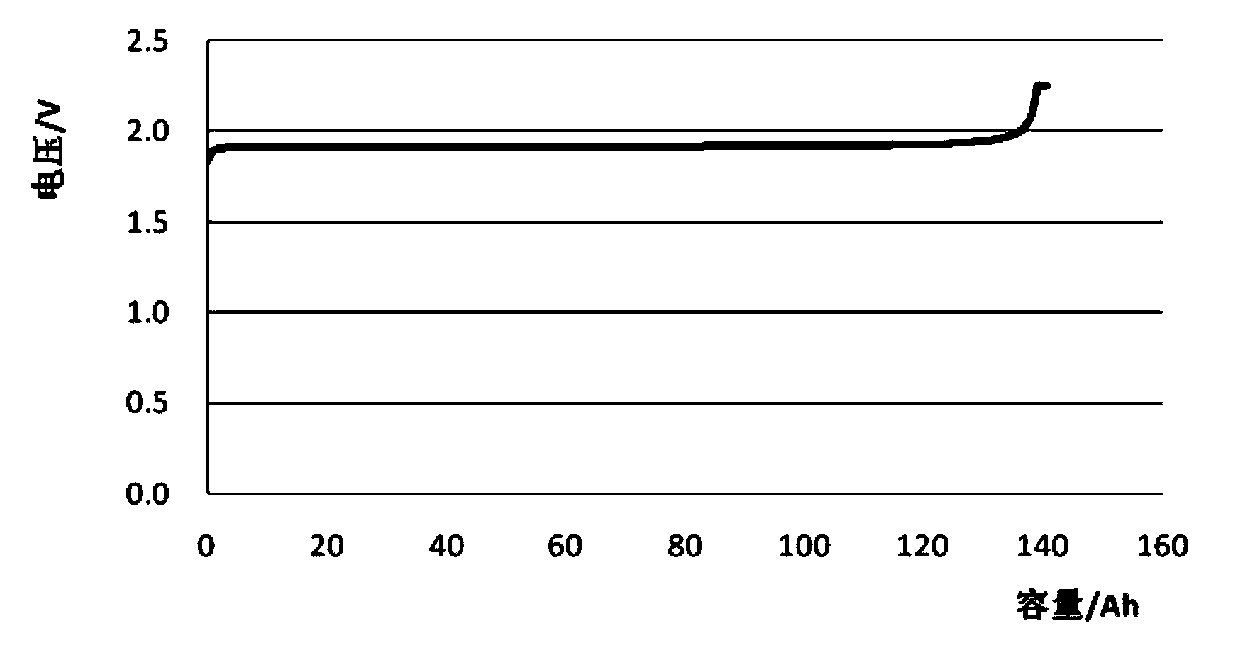

Image

Examples

Embodiment 1

[0026] The formula composition of a kind of lithium-ion power battery negative pole piece material is as follows table 1:

[0027]

[0028] The formula composition of a kind of lithium-ion power battery cathode sheet material is as follows table 2:

[0029]

[0030] Diaphragm: PP single-layer diaphragm

[0031] Electrolyte: 1.2mol / L LiPF 6 Solution, the solvent composition is EC:DMC:EMC=1:1:1

[0032] The shell is a plastic shell

[0033] The specific preparation method is as follows:

[0034] 1) Production of positive electrode sheet: Add positive electrode material according to the formula, add solvent to dissolve, stir evenly with double star power mixer at high speed, eliminate air bubbles and iron filings, and obtain positive electrode slurry, pass positive electrode slurry through automatic feeding system, coating machine evenly coated on aluminum foil, baked at 80°C for 12 hours in a vacuum environment, rolled, cut into positive electrode pieces;

[0035] 2) ...

Embodiment 2

[0039] The formula composition of a kind of lithium-ion power battery negative pole piece material is as follows table 3:

[0040]

[0041] The formula composition of a kind of lithium-ion power battery cathode sheet material is as follows table 4:

[0042]

[0043] Diaphragm: PP single-layer diaphragm

[0044] Electrolyte: 1.2mol / L LiPF 6 Solution, the solvent composition is EC:DMC:EMC=1:1:1

[0045] The shell is a plastic shell

[0046] The specific preparation method is as follows:

[0047] 1) Production of positive electrode sheet: Add positive electrode material according to the formula, add solvent to dissolve, stir evenly with double star power mixer at high speed, eliminate air bubbles and iron filings, and obtain positive electrode slurry, pass positive electrode slurry through automatic feeding system, coating machine evenly coated on the aluminum foil, in a vacuum environment, baked at 100 ℃ for 10 hours, rolled, cut into positive electrode pieces;

[004...

Embodiment 3

[0052] The formula composition of a kind of lithium-ion power battery negative pole piece material is as follows table 5:

[0053]

[0054] The formula composition of a kind of positive pole plate material of lithium-ion power battery is as follows table 6:

[0055]

[0056] Diaphragm: PP single-layer diaphragm

[0057] Electrolyte: 1.2mol / L LiPF 6 Solution, the solvent composition is EC:DMC:EMC=1:1:1

[0058] The shell is a plastic shell

[0059] The specific preparation method is as follows:

[0060] 1) Production of positive electrode sheet: Add positive electrode material according to the formula, add solvent to dissolve, stir evenly with double star power mixer at high speed, eliminate air bubbles and iron filings, and obtain positive electrode slurry, pass positive electrode slurry through automatic feeding system, coating machine evenly coated on aluminum foil, baked at 120°C for 5 hours in a vacuum environment, rolled, cut into positive electrode pieces;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com