Preparation method of econazole nitrate/polyacrylic resin cationic nanoparticles

A technology of polyacrylic acid resin and econazole nitrate, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Polyether F-68 was dissolved in phosphate buffer to obtain an aqueous phase, econazole nitrate and polyacrylic resin RS100 were dissolved in a mixed solution of acetone and ethanol to obtain an organic phase, and the organic phase was added to water Reaction in phase to obtain primary econazole nitrate / polyacrylic acid resin nanoparticle colloidal solution, then use vacuum evaporation method combined with ultrafiltration to remove organic solvent and unreacted F-68, then add osmotic pressure regulator and antibacterial agent and a buffering agent, and finally adjust the pH value to 4.5-7.0 to obtain econazole nitrate / polyacrylic acid resin nanoparticles.

[0015] The osmotic pressure regulator is glycerin or mannitol, the bacteriostatic agent is benzalkonium chloride, benzalkonium bromide or ethylparaben, and the buffer is phosphate. The phosphate is NaH 2 PO 3 、Na 2 HPO 3 or KH 2 PO 3 . The aqueous phase is prepared by dissolving 1 gram of F-68 in 50-...

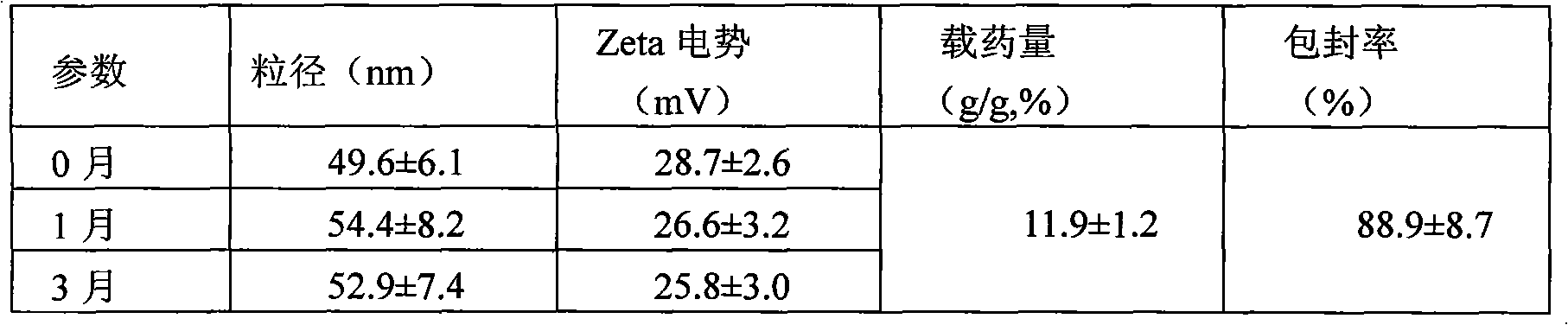

Embodiment 2

[0016] Example 2: Take 1.0 g of polyether F-68 and dissolve it in 80 ml of disodium hydrogen phosphate buffer solution with a pH of 5.85 to obtain an aqueous phase.

[0017] Take 2ml of acetone and 13ml of ethanol and mix evenly, dissolve 0.0613g of econazole nitrate and 0.3635g of RS100 in the above mixture, and shake fully to dissolve the two to obtain the organic phase.

[0018] Take the organic phase, slowly drop it into the water phase under stirring, continue stirring for 30 minutes after injection, and obtain the primary econazole nitrate / polyacrylic acid resin nanoparticle colloid solution A.

[0019] Take liquid A, and remove the organic solvent under vacuum at a constant temperature of 60°C until the volume is reduced to 60ml to obtain liquid B.

[0020] Take liquid B, dilute to 100ml, perform ultrafiltration with vivo-50 ultrafilter, concentrate to 20ml, and then dilute to 100ml, repeat 3 times to obtain liquid C.

[0021] Take 50ml of liquid C, add 0.4g of disodiu...

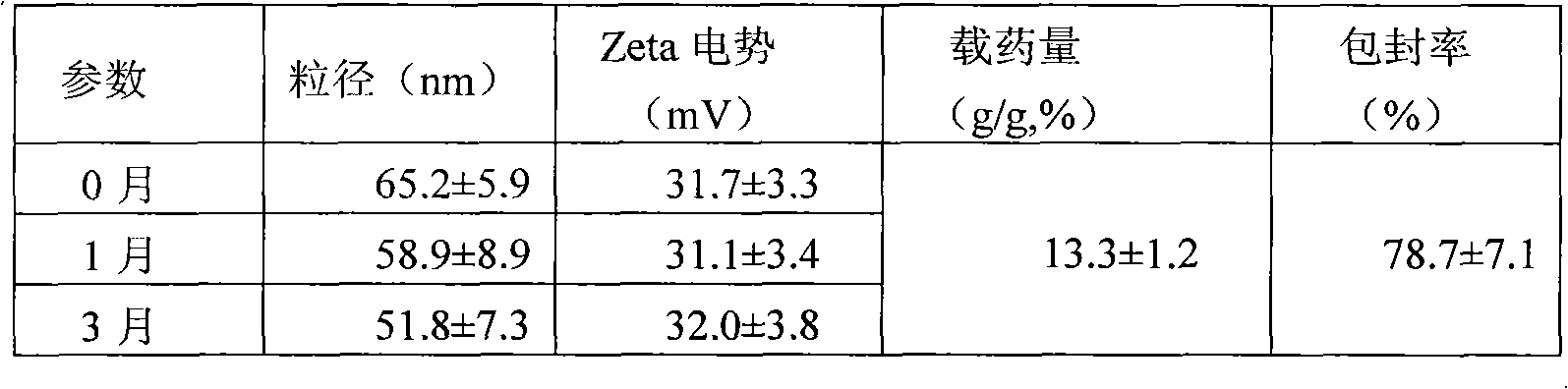

Embodiment 3

[0024] Example 3: 1.1 g of F-68 was taken and dissolved in 100 ml of disodium hydrogen phosphate buffer solution with a pH of 5.85 to obtain an aqueous phase.

[0025] Mix 4ml of acetone with 20ml of ethanol. Dissolve 0.0635g of econazole nitrate and 0.4756g of RS100 in the above mixed liquid, shake fully to dissolve the two to obtain the organic phase.

[0026] Take the organic phase, stir it, slowly drop it into the water phase, and continue stirring for 30 minutes after injection to obtain the primary econazole nitrate / polyacrylic acid resin nanoparticle colloid solution A.

[0027] Take liquid A, and remove the organic solvent under vacuum at a constant temperature of 60°C until the volume is reduced to 80ml to obtain liquid B.

[0028] Take liquid B, dilute it to 125ml, perform ultrafiltration with a vivo-50 ultrafilter, concentrate to 25ml, and then dilute to 125ml, repeat 3 times to obtain liquid C.

[0029] Take 50ml of liquid C, add 0.25g of disodium hydrogen phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com