Organic electronic device

A technology of organic electronic devices and devices, applied in the direction of electric solid devices, electrical components, organic chemistry, etc., can solve problems such as voltage increase, high voltage, and shortened life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

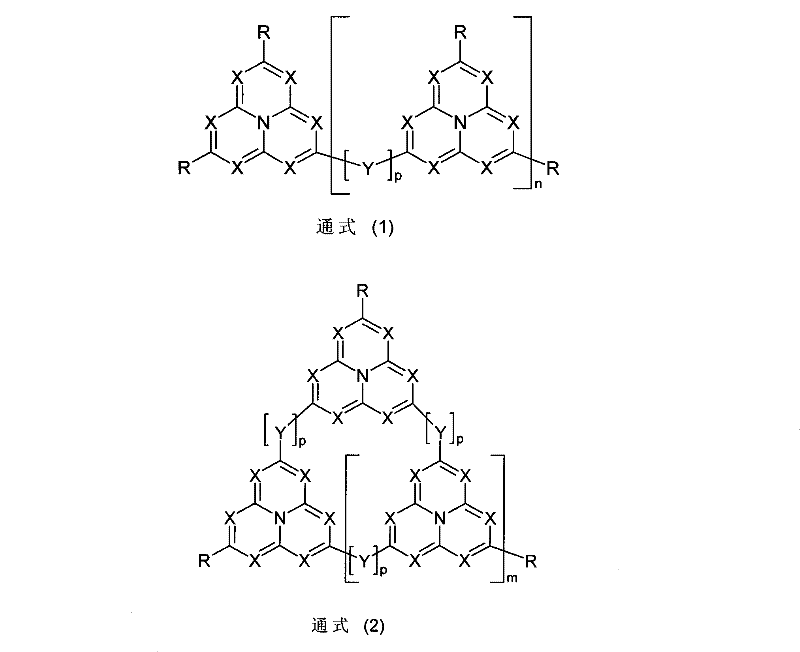

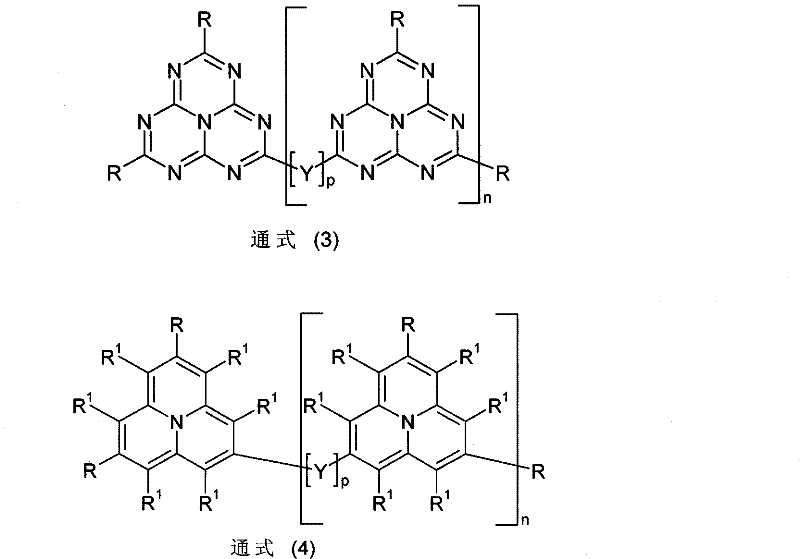

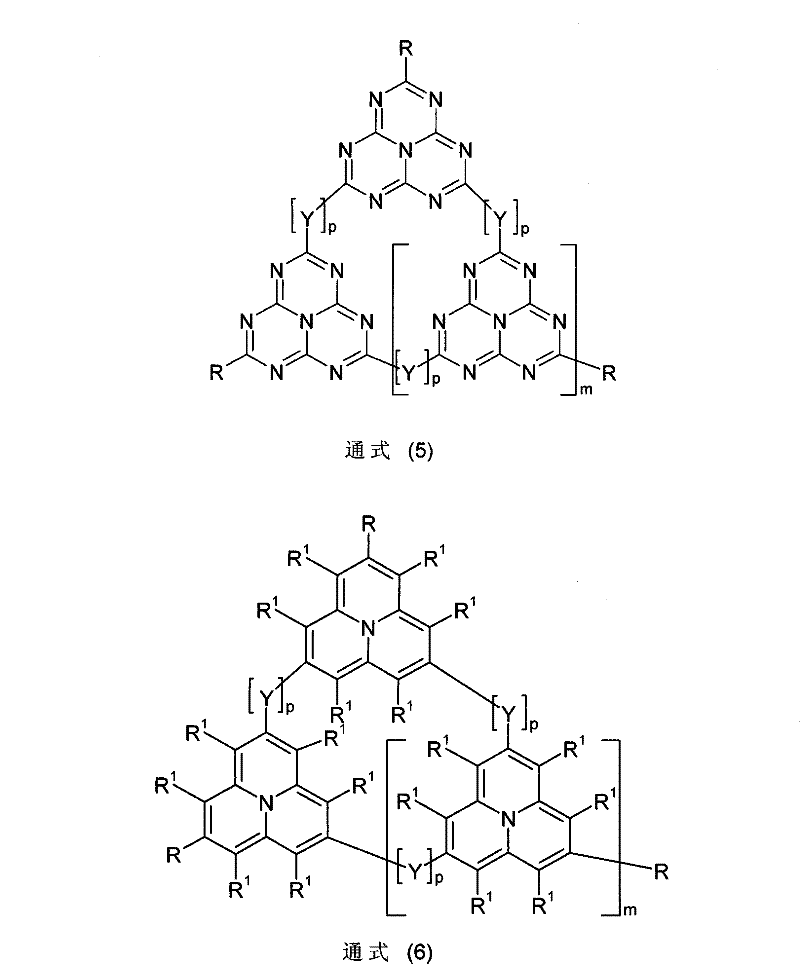

Method used

Image

Examples

Embodiment 1

[0104] Example 1: Synthesis of Tricyanoheptaazaphenene (HIM-1)

[0105]

[0106] 50 g (181 mmol) of trichloroheptaazafinene and 53.45 g (597 mmol, 3.3 equivalents) of copper (I) cyanide were suspended in 750 ml of DMF and heated at 130° C. for 60 h under argon. After cooling to room temperature, the reaction mixture was added to 1000 ml of concentrated ammonia solution and vigorously stirred in the air for 4 h. The organic precipitate precipitated in the process was filtered with suction and washed with cold ethanol. The residue was extracted with acetonitrile in a Soxhlet extractor, and the crystalline precipitate was filtered off with suction, washed with a little cold acetonitrile and dried under vacuum. Yield: 39.1 g (157 mmol), 87% of theory; purity is about 99.8% (HPLC).

Embodiment 2

[0107] Example 2: Manufacturing and characterization of organic electroluminescent devices

[0108] The OLED of the invention is manufactured by a general method according to WO 04 / 058911, which method has to be adapted to the situation described here (layer-thickness variation, material used).

[0109] In the following Examples 3 to 8, the results of various OLEDs are provided. A glass plate coated with structured ITO (Indium Tin Oxide) forms the base of the OLED. For improved processing, 20nm PEDOT (spin-coated from water; purchased from HCStarck, Goslar, Germany; poly(3,4-ethylenedioxy-2,5-thiophene)) was applied to the substrate on. The OLED consists of the following layer sequence: substrate / PEDOT 20nm / hole injection layer (HIL) 5nm / hole transport layer (HTM-1) 20nm / hole transport layer (HTL-2) 20nm / light emitting layer (EML) 30nm / Electron transport layer (ETM) 20nm and the final cathode.

[0110] The material except PEDOT is applied by thermal vapor deposition in a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com