Preparation method for S-adenosine-L-methionine disulfate tosylate

A technology of toluenesulfonic acid sulfuric acid and p-toluenesulfonic acid, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of reduced heating and cooling speed, increased heating unevenness, equipment and operation Require high-level problems, achieve the effect of less impurity adsorption, high product recovery rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

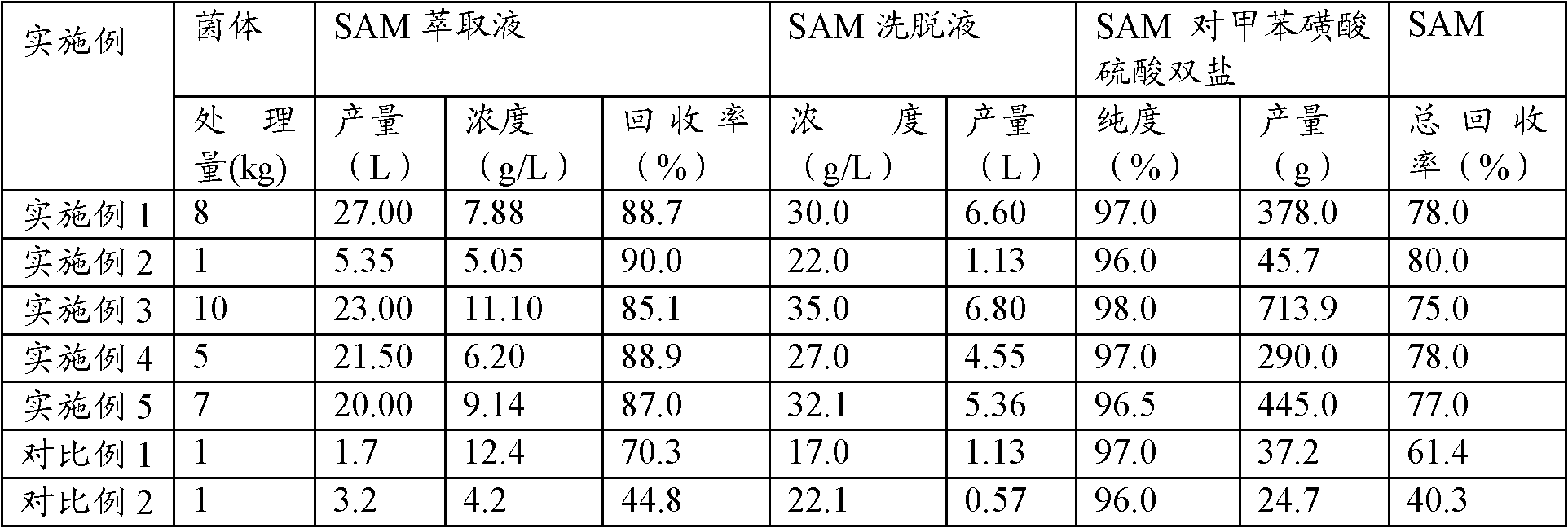

Examples

Embodiment 1

[0030](1) During the fermentation process for preparing SAM, Saccharomyces cerevisiae is used for high-density fermentation, and the precursor L-methionine is added to make the obtained fermentation broth have a higher SAM-rich bacterial cell content. After the fermentation, 30 L of fermentation broth was centrifuged at 6000 rpm for 10 min at 4° C. to obtain about 10 kg of wet bacteria.

[0031] (2) Take 8kg of wet bacteria prepared in step (1), add 24L of 50°C, 0.1M H 2 SO 4 The solution was homogenized at 50° C. for 1 hour, and the homogenizer rotated at 500 rpm. After the cells were crushed, the temperature was cooled with cold water, and the cells were centrifuged at 6000 rpm for 10 min at 4°C to remove the cell fragments to obtain the SAM extract. The yield, concentration and yield are shown in Table 1.

[0032] (3) Using an ultrafiltration membrane with a molecular weight cut-off of 10,000 to perform ultrafiltration on the SAM extract obtained in step (2) to remove pro...

Embodiment 2

[0038] Embodiment 2 is different from embodiment 1 in that:

[0039] (2) Take 1kg of the wet bacteria obtained in step (1), add 5L of 30°C, 0.2M H 2 SO 4 The solution was homogenized for 3 hours at 30° C., and the speed of the homogenizer was 300 rpm. The results are shown in Table 1.

[0040] (3) Using an ultrafiltration membrane with a molecular weight cut-off of 6000 to carry out ultrafiltration treatment on the SAM extract prepared in step (2).

[0041] (4) adjust the pH of the SAM filtrate prepared by step (3) to 7 with 20% NaOH solution, send into an ion exchange column with a column volume of about 0.3L for ion exchange treatment, and the exchange capacity of its resin is 90g / L resin, the feed concentration of SAM is 4.0g / L, the feed speed is 4.0BV / h, and the feed amount is 22.5BV; the consumption of deionized water is 5BV, and the flow rate is 1BV / h; the concentration of sulfuric acid solution is 0.05M, the flow rate is 1BV / h, the results are shown in Table 1.

[...

Embodiment 3

[0046] Embodiment 3 is different from embodiment 1 in that:

[0047] (2) Take 10kg of wet bacteria prepared in step (1), add 20L of 60°C, 0.5M H 2 SO 4 The solution was homogenized at 60°C for 0.5h, and the speed of the homogenizer was 600rpm. The results are shown in Table 1.

[0048] (3) Using an ultrafiltration membrane with a molecular weight cut-off of 6000 to carry out ultrafiltration treatment on the SAM extract prepared in step (2).

[0049] (4) adjust the pH of the SAM filtrate prepared by step (3) to 4 with 20% NaOH solution, send into an ion exchange column with a column volume of about 2.1L for ion exchange treatment, and the exchange capacity of its resin is 120g / L resin, the feed concentration of SAM is 10.0g / L, the feed rate is 1.0BV / h, and the feed amount is 12.0BV; the consumption of deionized water is 4BV, and the flow rate is 2BV / h; the concentration of sulfuric acid solution is 0.25M, the flow rate is 4BV / h, the results are shown in Table 1.

[0050] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com