Exterior wall fireproof emulsion paint

A fire-resistant latex and exterior wall technology, applied in latex paint, fire-resistant paint, coating and other directions, can solve the problem that the storage and transportation environment temperature is greatly affected, the scope and method of use of fire-resistant paint are limited, and the water-based fire-resistant paint coating is resistant to water and heat. Moisture resistance is not as good as other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

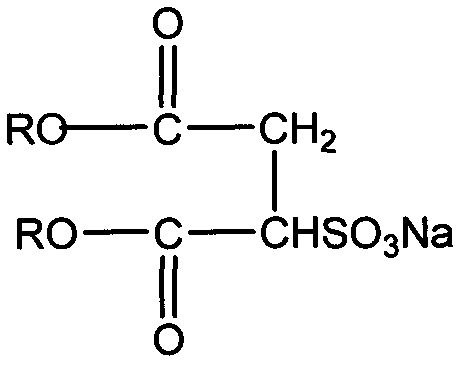

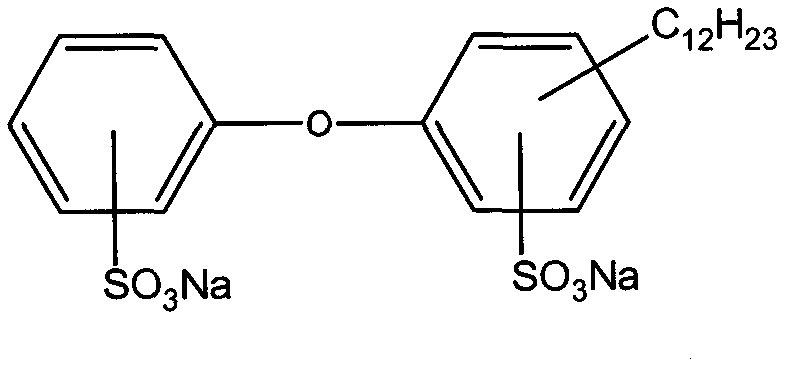

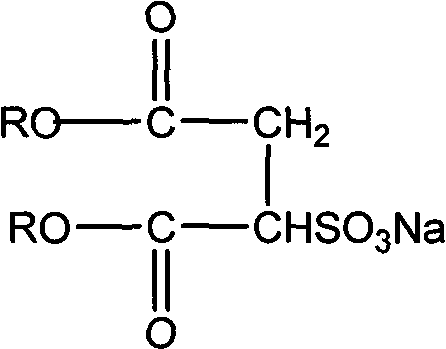

[0035] The invention provides a powder exterior wall latex paint, comprising redispersible acrylic rubber powder, ammonium polyphosphate, heavy calcium carbonate, titanium dioxide, barium sulfate, silicon micropowder, glass microbead carrier, nano-montmorillonite, and melamine , Tributyl Phosphate, Ammonium Dihydrogen Phosphate, Sodium Polyacrylate, Sodium Hexametaphosphate, Sodium Isopropyl Naphthalene Sulfonate, Aerosol Sodium Salt Anionic Surfactant, Sodium Disulfonated Oxydecyl Dibenzene Sulfonate, N - disodium octadecyl sulfosuccinate, Triton nonylphenol nonionic surfactant, sodium bicarbonate, the weight percent value of each component is: redispersible acrylic rubber powder 25.0%, ammonium polyphosphate 2.5% , calcium carbonate 9.0%, titanium dioxide 10.0%, barium sulfate 15.0%, silica powder 15.0%, glass microbead carrier 10.0%, nano-montmorillonite 1.0%, melamine 0.6%, tributyl phosphate 0.04%, ammonium dihydrogen phosphate 1.5%, Sodium Polyacrylate 1.5%, Sodium Hexam...

Embodiment 2

[0039] The invention provides a powder exterior wall latex paint, comprising redispersible acrylic rubber powder, ammonium polyphosphate, heavy calcium carbonate, titanium dioxide, barium sulfate, silicon micropowder, glass microbead carrier, nano-montmorillonite, and melamine , Tributyl Phosphate, Ammonium Dihydrogen Phosphate, Sodium Polyacrylate, Sodium Hexametaphosphate, Sodium Isopropyl Naphthalene Sulfonate, Aerosol Sodium Salt Anionic Surfactant, Sodium Disulfonated Oxydecyl Dibenzene Sulfonate, N - disodium octadecyl sulfosuccinate, Triton nonylphenol nonionic surfactant, sodium bicarbonate, the weight percentage value of each component is: redispersible acrylic rubber powder 30.0%, ammonium polyphosphate 2.0% , calcium carbonate 8.0%, titanium self-powder 12.0%, barium sulfate 10.0%, silica powder 12.0%, glass microbead carrier 13.5%, nano-montmorillonite 1.5%, tripolyhydrogen amine 0.5%, tributyl phosphate 0.02%, dihydrogen phosphate Ammonium 2.0%, Sodium Polyacrylat...

Embodiment 3

[0043] The invention provides a powder exterior wall latex paint, comprising redispersible acrylic rubber powder, ammonium polyphosphate, heavy calcium carbonate, titanium dioxide, barium sulfate, silicon micropowder, glass microbead carrier, nano-montmorillonite, and melamine , Tributyl Phosphate, Ammonium Dihydrogen Phosphate, Sodium Polyacrylate, Sodium Hexametaphosphate, Sodium Isopropyl Naphthalene Sulfonate, Aerosol Sodium Salt Anionic Surfactant, Sodium Disulfonated Oxydecyl Dibenzene Sulfonate, N - disodium octadecyl sulfosuccinate, Triton nonylphenol nonionic surfactant, sodium bicarbonate, the weight percent value of each component is: redispersible acrylic rubber powder 35.0%, ammonium polyphosphate 2.0% , calcium carbonate 10.0%, titanium dioxide 15.0%, barium sulfate 10.0%, silica powder 10.0%, glass microbead carrier 14.0%, nano-montmorillonite 1.0%, melamine 0.8%, tributyl phosphate 0.06%, ammonium dihydrogen phosphate 1.8%, Sodium Polyacrylate 2.5%, Sodium Hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com