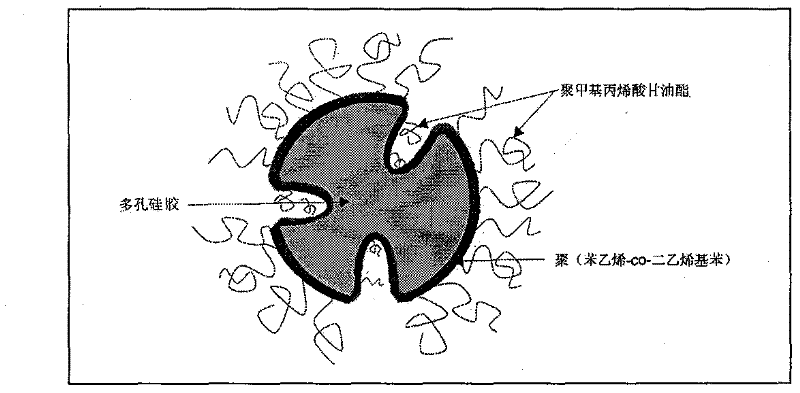

Restricted access poly (styrene-co-divinyl benzene)-coated silica gel chromatographic packing and preparation method thereof

A technology of silica gel chromatography and divinylbenzene, applied in chemical instruments and methods, material separation, analysis of materials, etc., can solve the problem of high cost, achieve the effects of reducing loss, good exclusion effect, and reducing catalytic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

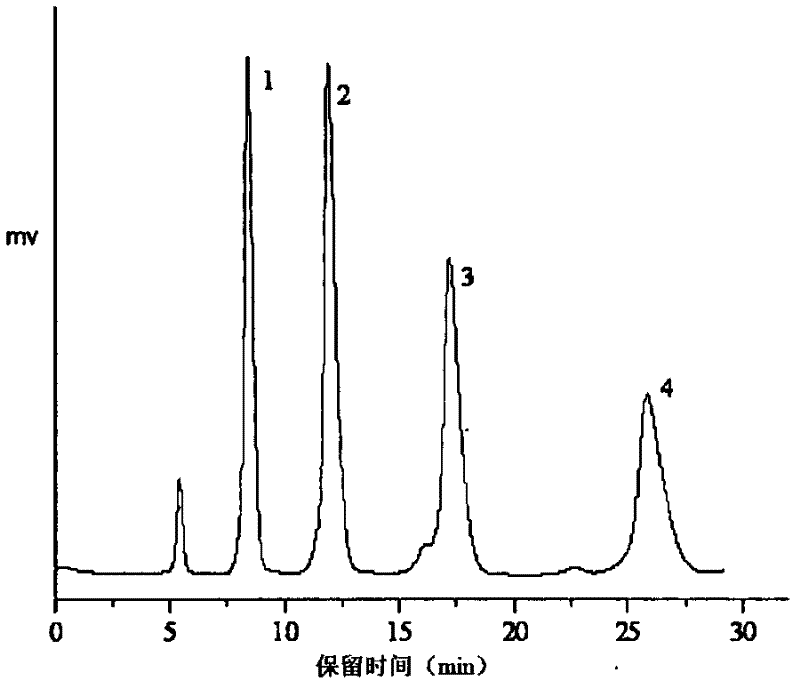

Examples

Embodiment 1

[0052] 1. Preparation of ATRP initiator-immobilized silica gel

[0053] Weigh 15.0 g of activated silica gel microspheres, disperse them in 150 ml of dry toluene, and 2 Under protection, 18.0 ml of γ-aminopropyltrimethoxysilane reagent was added, stirred and refluxed at 110° C. for 12 hours. The reaction product was suction-filtered, washed with toluene, acetone, and in turn. Vacuum drying at 60°C, the product is marked as Sil-NH 2 .

[0054] Sil-NH 2 Transfer to a round-bottomed flask, add 120 ml of dry cyclohexanone, stir to disperse, and 2 Under protection, 30 ml of cyclohexanone solution containing 9.98 g of 4-chloromethylbenzoyl chloride was added dropwise in an ice-water bath, and 1.2 ml of pyridine was added, and the reaction was stirred at room temperature for 18 hours. After the reaction, the product was suction-filtered, and then Soxhlet extracted with acetone, and the obtained product was labeled as Sil-Cl. Dry in a vacuum oven at 60°C for later use.

[0055]...

Embodiment 2

[0061] The 2nd step in embodiment 1 adopts following experimental condition: pass N 2 Under gas conditions, add 2.5 grams of Si-Cl (initiator content is 1.3 mmol / g) in the there-necked flask after drying, 14 milliliters of toluene, mechanical stirring makes silica gel disperse, adds styrene 3.6 grams (34.6 mmol) successively , 0.34 g (3.4 mmol) of cuprous chloride and 1.07 g (6.9 mmol) of 2,2′-bipyridine, heated at 110° C. in an oil bath, and refluxed for 4 hours to obtain polystyrene-coated silica gel. The product is sequentially washed with ethanol and Na 2 Washing with saturated EDTA solution, then Soxhlet extraction with acetone for 12 hours, vacuum drying at 50°C for later use, to obtain polystyrene-coated silica gel, the carbon content was 25.4% as determined by elemental analysis.

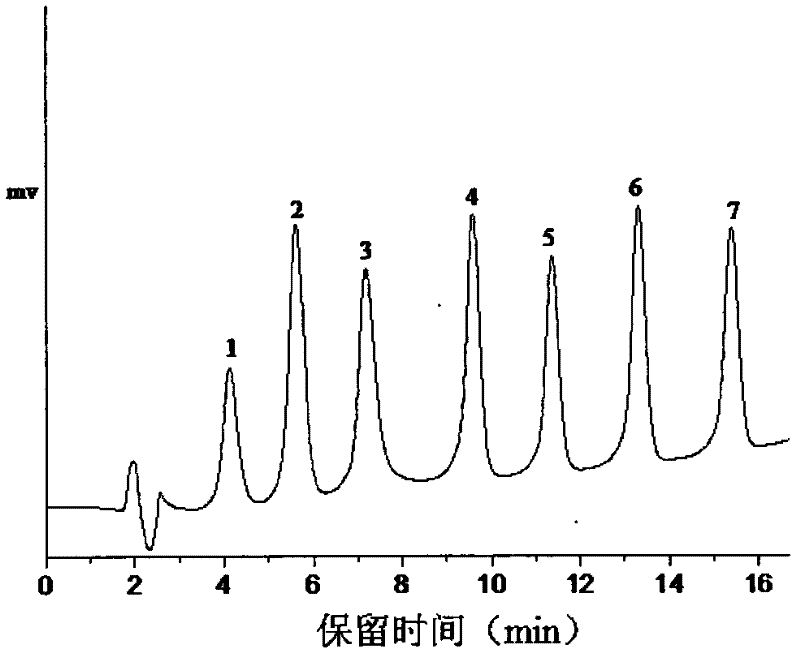

Embodiment 3

[0063] The second step in Example 1 adopts the following experimental conditions: add 2.5 grams of Si-Cl (initiator content is 0.6 mmol / g) and 8 milliliters of toluene to the dried there-necked flask, mechanically stir to disperse the silica gel, and then add 0.73 g (7.02 mmol) of styrene, 0.83 g (6.38 mmol) of divinylbenzene, 0.4 g (2.56 mmol) of 2,2′-bipyridine, 0.125 g (1.26 mmol) of cuprous chloride, oil The bath was heated at 110° C. and refluxed for 2 hours to obtain poly(styrene-co-divinylbenzene)-coated silica gel. The product is sequentially washed with ethanol and Na 2 Wash with saturated EDTA solution, then Soxhlet extract with acetone for 12 hours, and vacuum-dry at 50°C for later use. The carbon content is 26% as measured by elemental analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com