Integral management method for acid sewage generated in titanium white powder production process

A production process, acid sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve problems such as waste, high hardness, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

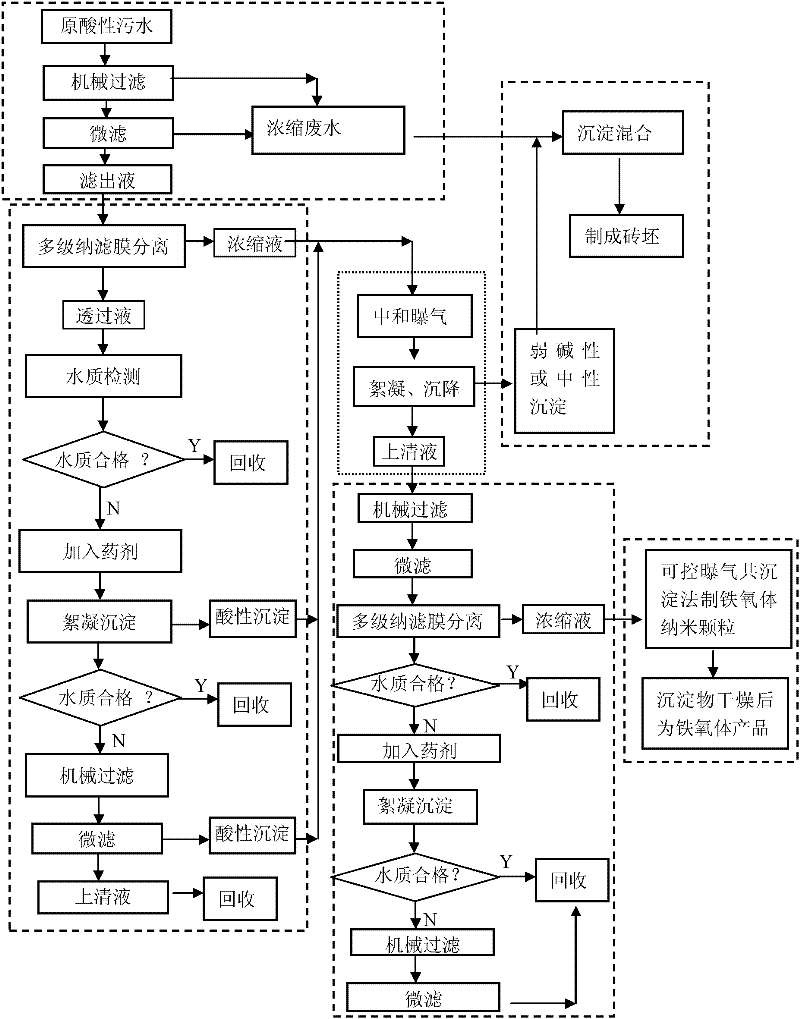

[0043] This embodiment provides a comprehensive treatment method for acid sewage produced in the production process of titanium dioxide, which mainly includes the following steps:

[0044] Step 1: The acidic sewage is subjected to coarse filtration and microfiltration treatment processes for preliminary impurity removal.

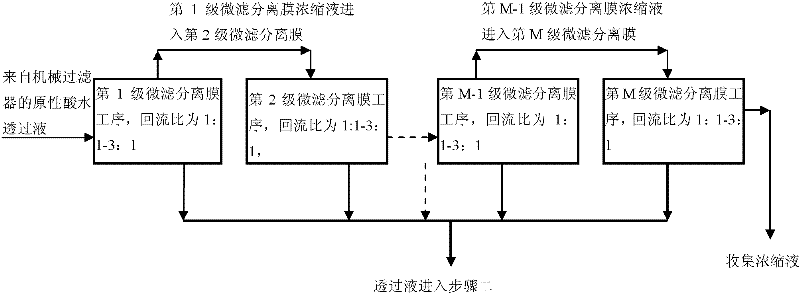

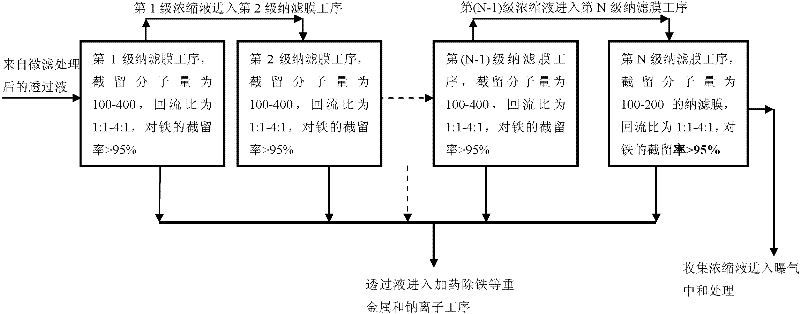

[0045] In this step, first pass the acid sewage generated in the production process of titanium dioxide with a flow rate of 10,000 tons / day through a mechanical filter, use a mechanical filter or a bag filter with a filtration accuracy of 20.0 μm for mechanical filtration, and then use a microfiltration system for microfiltration. Filtration treatment, the microfiltration system is composed of four-stage (M=4) microfiltration separation membrane processes, such as Figure 4 shown, and adopts polypropylene microfiltration separation membrane (such as KJESUF9050X50 / 80) with a membrane pore of 0.5 μm (molecular weight cut-off 80,000), according to the treatment...

Embodiment 2

[0076] The difference between this embodiment and embodiment 1 is that step 6 is added after step 5: ferrite preparation process. This process combines the controllable aeration / oxidation co-precipitation method with the patent "a preparation method of ferrite nanoparticles" (CN201110102232.4) to prepare nano ferrite. The controllable aeration process is based on the content of divalent and ferric iron in the concentrated solution obtained in step 4, adopting air bubbling at the bottom of the container for storing the concentrated solution to oxidize part of the ferrous iron into ferric iron, so that the ferrous iron The molar ratio of iron and ferric iron satisfies the FeCl in step one in the patent 2 4H 2 O and FeCl 3 ·6H 2 The molar ratio of O, specifically the molar ratio of ferrous iron and ferric iron is preferably 1:2; then the mixed iron salt co-precipitation technology in patent CN201110102232.4 is used to prepare highly dispersed soluble nano-ferrite.

[0077] ...

Embodiment 3

[0080] The difference between this embodiment and Example 1 is that in step one, the flow rate is 10,000 tons / day through the mechanical filter, and then 6 stages of microfiltration separation membrane processes are used (the reflux ratio of each stage of microfiltration separation membrane process is 2: 1 ) The polysulfone microfiltration separation membrane connected in series at the outlet of the retentate treats the permeate through the mechanical filter, and the water fluxes of each microfiltration separation membrane process are 125 tons / hour, 83 tons / hour, and 56 tons / hour respectively , 37 tons / hour, 25 tons / hour and 16 tons / hour, the total reflux ratio still reaches 1:9. The microfiltration system can remove impurities such as suspended solids and partially dissolved solids in raw acid water, the total solid content is reduced from 150g / L to 30g / L, and the color of the filtrate also changes from milky white turbid to colorless and clear. Other indicators Still can rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com