Preparation method for metal-based MFI type zeolite molecular sieve film

A zeolite molecular sieve membrane, metal-based technology, which is applied in the preparation of molecular sieve catalysts, liquid hydrocarbon mixtures, chemical instruments and methods, etc., can solve the problems of difficult control of molecular sieve membrane thickness and thermal conductivity, etc., to improve the anti-mechanical vibration performance and thermal conductivity. performance, strengthen the bond strength, solve the effect of discontinuous problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Comparison of firmness of metal-based molecular sieve membrane composites prepared by three methods

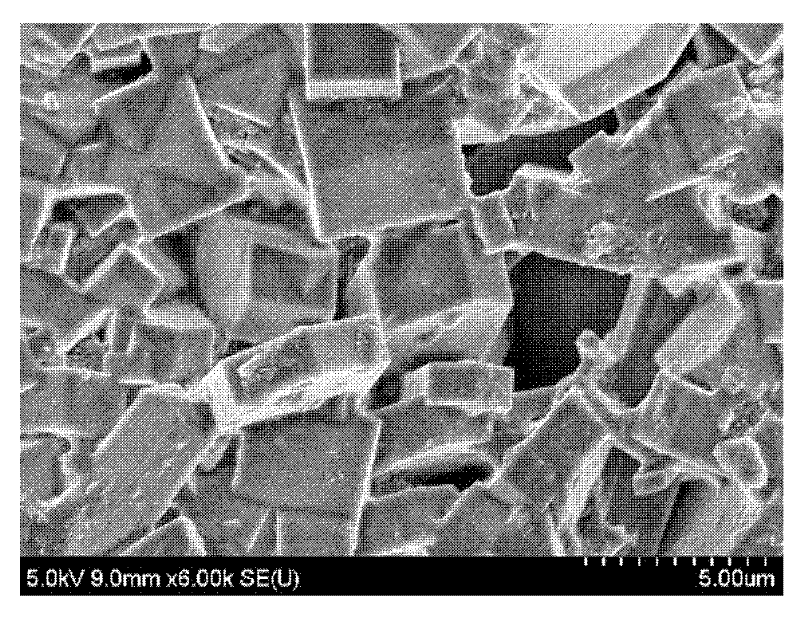

[0057] Method 1: Direct growth of MFI molecular sieve membrane by in-situ hydrothermal method

[0058] Dissolve 1.5mL of 2.214moL / L TPAOH as template agent in 3.2g of water and stir evenly. Then, under the condition of stirring, 2.0 g of TEOS was slowly added dropwise, stirred at room temperature for 6 h, and a clear synthetic solution was obtained. Put the treated stainless steel carrier on the polytetrafluoroethylene support, put it vertically into a stainless steel crystallization kettle with a polytetrafluoroethylene lining, then pour the synthetic solution prepared above into the kettle, and put the stainless steel carrier Submerged and hydrothermally synthesized at 175°C for 24h. After taking out the kettle, cool it with rapid water, take out the stainless steel carrier, rinse it repeatedly with deionized water, clean it with ultrasonic vibration, and...

Embodiment 2

[0087] Example 2: Applying metal-based MFI-type zeolite molecular sieve membrane composite catalytic materials to low-concentration methane catalytic combustion

[0088] Step 1: Pretreatment of Stainless Steel Support

[0089]Polish the surface of stainless steel with 30 mesh, 240 mesh, and 1000 mesh sandpaper, then wash with ethanol and deionized water to remove the grease on the surface, and put 30wt% concentration of H 2 o 2 Soak in water for 30 minutes, take out, rinse, and dry for later use;

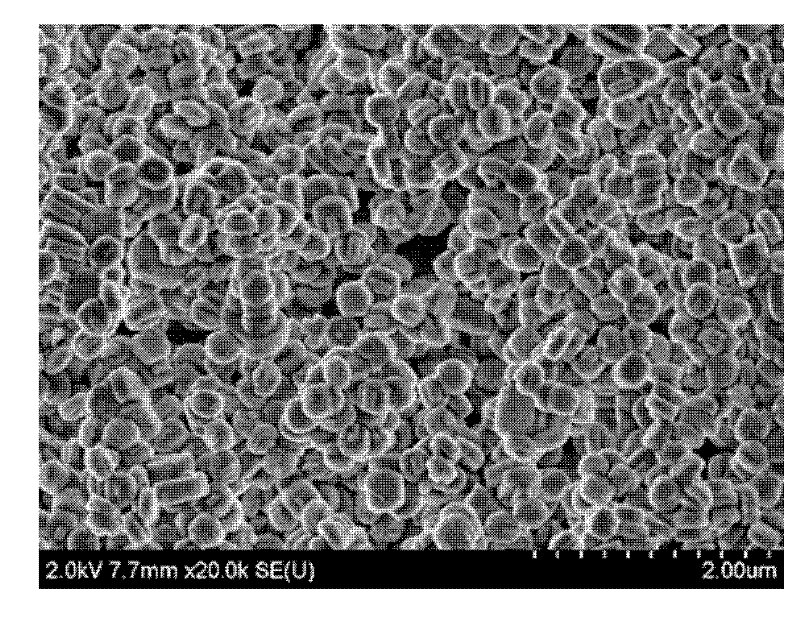

[0090] Step 2: Preparation of Silicalite-1 zeolite membrane seed transition layer by in-situ hydrothermal synthesis on stainless steel support

[0091] In an Erlenmeyer flask, mix TEOS, TPAOH and H 2 O by TEOS:TPAOH:H 2 O=1:0.32:165 ratio mixing. First add 1.734mL TPAOH with a concentration of 2.214moL / L to 34.56gH 2 O, 2.5 g of TEOS was added dropwise under stirring at 375 rpm or under the action of ultrasound. Then continue to stir and age for 5 hours to obtain a synthetic ...

Embodiment 3

[0104] Example 3: Applying metal-based molecular sieve membrane composite catalytic materials to Fischer-Tropsch synthesis reaction

[0105] Step 1: Pretreatment of Stainless Steel Support

[0106] After the stainless steel carrier is processed into a certain shape, it is washed with acetone to remove grease, then rinsed with deionized water, and put in 30wt% concentration of H 2 o 2 Soak in water for 30 minutes, take out, rinse, and dry for later use.

[0107] Step 2: In situ hydrothermal synthesis of Silicalite-1 zeolite membrane seed transition layer on stainless steel support

[0108] In an Erlenmeyer flask, mix TEOS, TPAOH and H 2 O by TEOS:TPAOH:H 2 O=1:0.32:165 ratio mixing. First add 1.734mL TPAOH with a concentration of 2.214moL / L to 34.56gH 2 O, 2.5 g of TEOS was added dropwise under stirring at 375 rpm or under the action of ultrasound. Then continue to stir and age for 5 hours to obtain a synthetic liquid of zeolite membrane. Fix the stainless steel carrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com